Product Feature

High-grade fire resistance and excellent thermal insulation performance

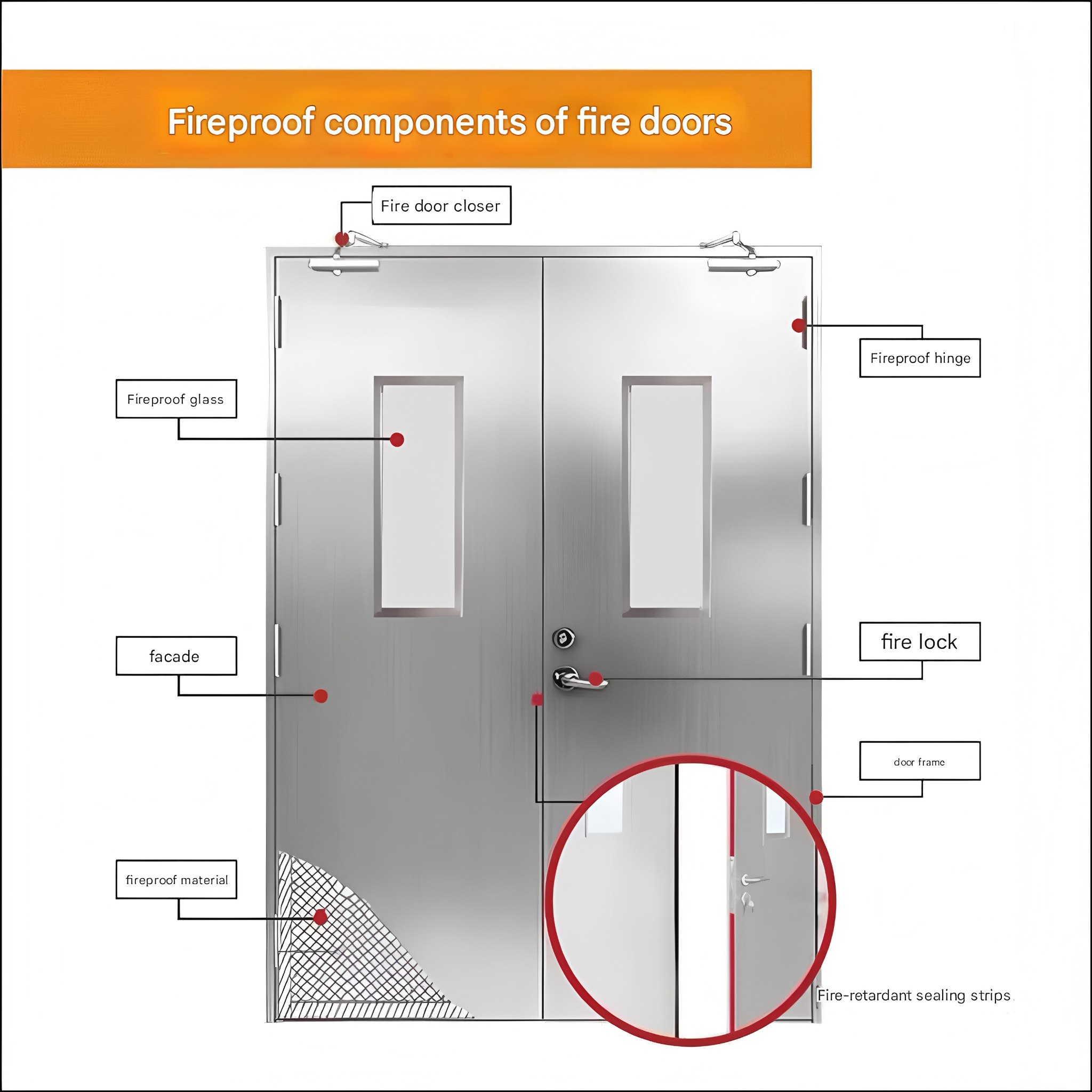

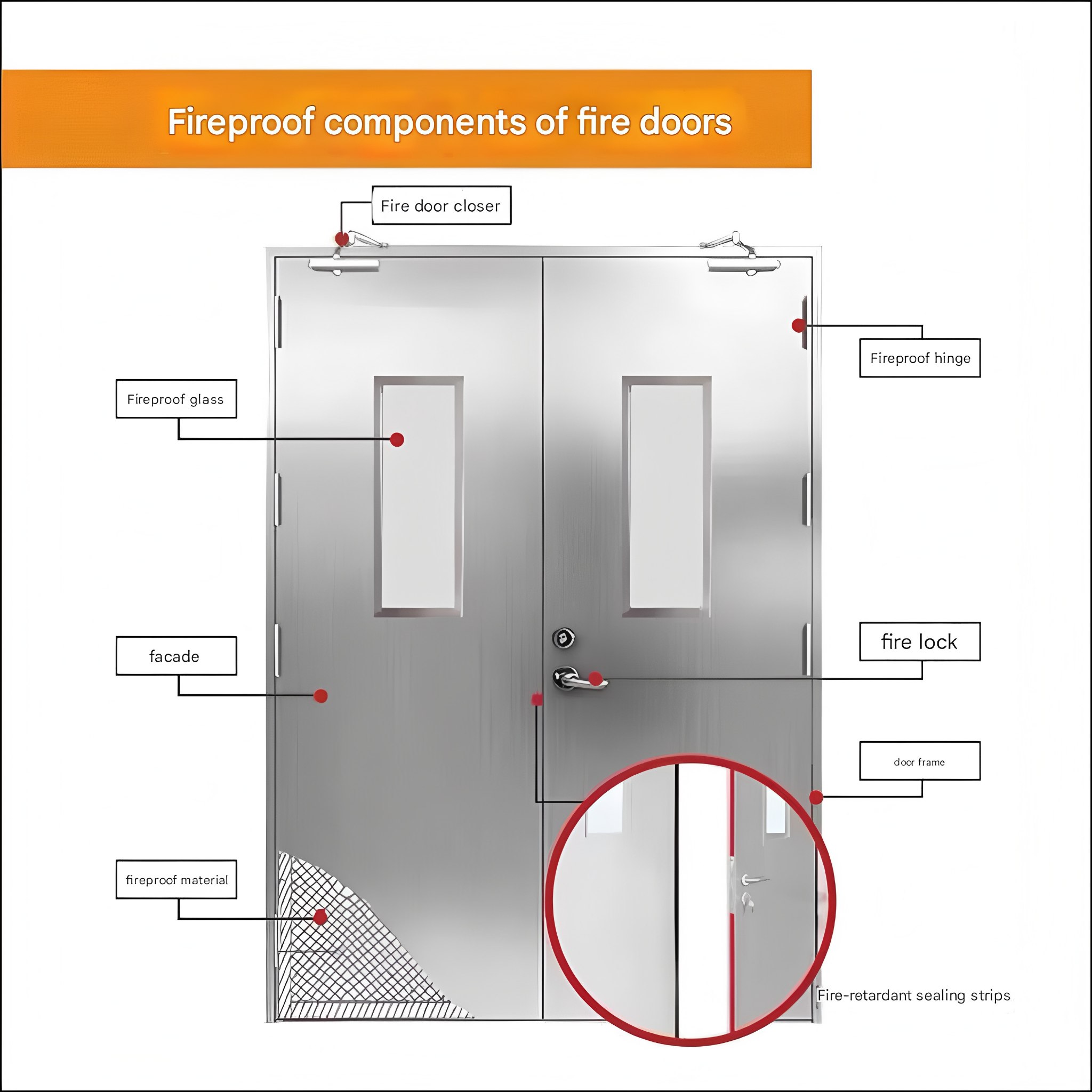

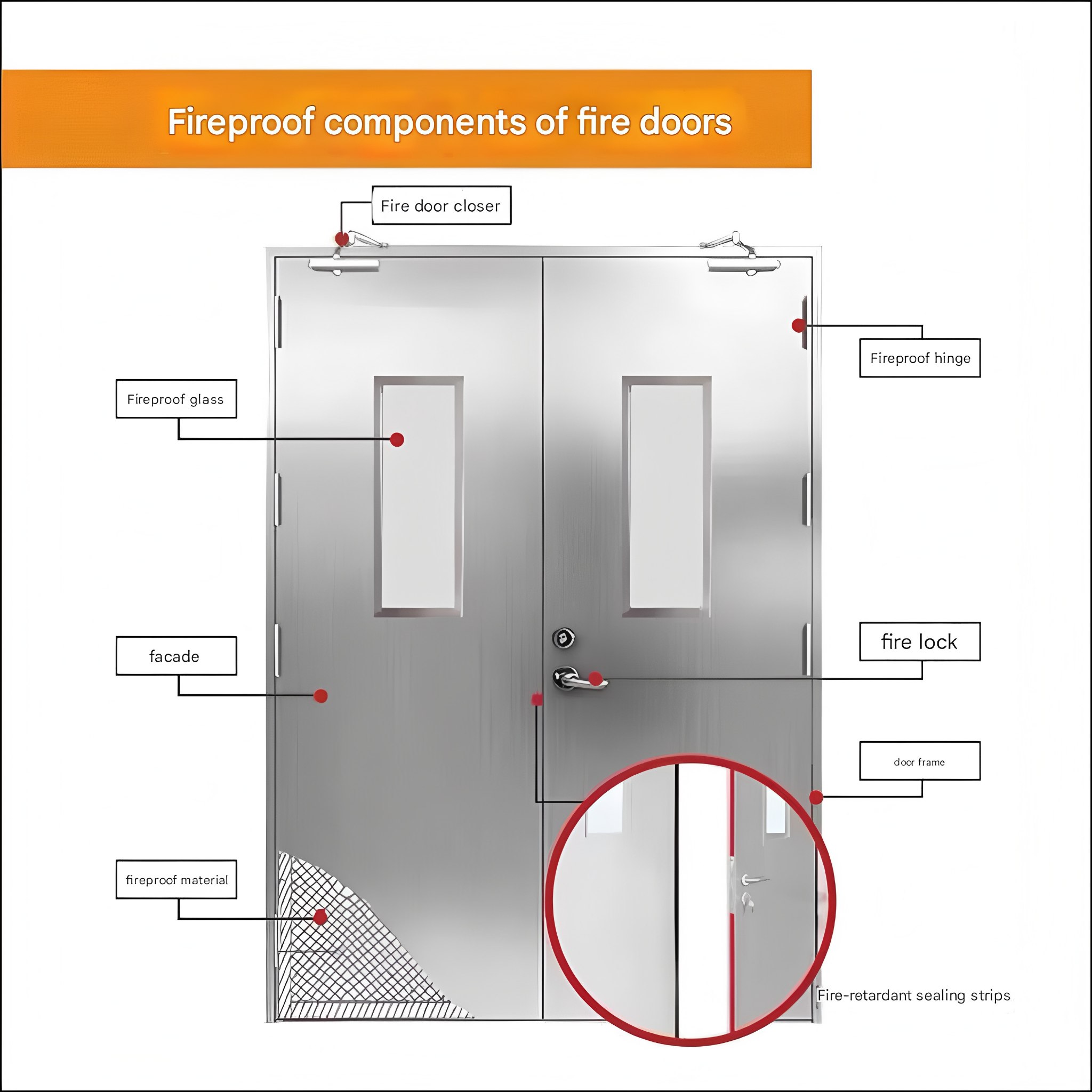

Manufactured from premium cold-rolled steel using an integrated forming process and filled with high-density fire-resistant insulating core material, the door meets stringent standards for fire integrity and thermal insulation. In case of fire, it effectively blocks flame spread and high-temperature transfer, providing valuable time for evacuation and emergency response.

Robust, durable, impact-resistant and anti�prying, with high anti-theft performance

The steel-plate structure delivers exceptional hardness, and the reinforced frame and door leaf, together with specialized fire-rated hardware, offer both fire-proof and anti-break-in protection. Its strong resistance to impact and prying ensures a long service life with minimal deformation or damage.

Precision engineering ensures tight sealing, superior sound and heat insulation

High-temperature-resistant fire seals are installed at the junctions between the frame and door leaf, expanding automatically under heat to close gaps. This effectively prevents smoke and flame penetration, reduces noise, and minimizes indoor-outdoor thermal transfer, combining fire safety with daily comfort and usability.

Compliance-driven, reliable quality, with complete certification

Strictly manufactured in accordance with national fire-door production standards, each product has passed authoritative national fire-safety testing and certification, and carries full acceptance credentials for fire-protection systems. All performance indicators meet regulatory requirements, ensuring smooth approval in fire-safety inspections.

Stable structure, easy to clean and maintain, and widely adaptable

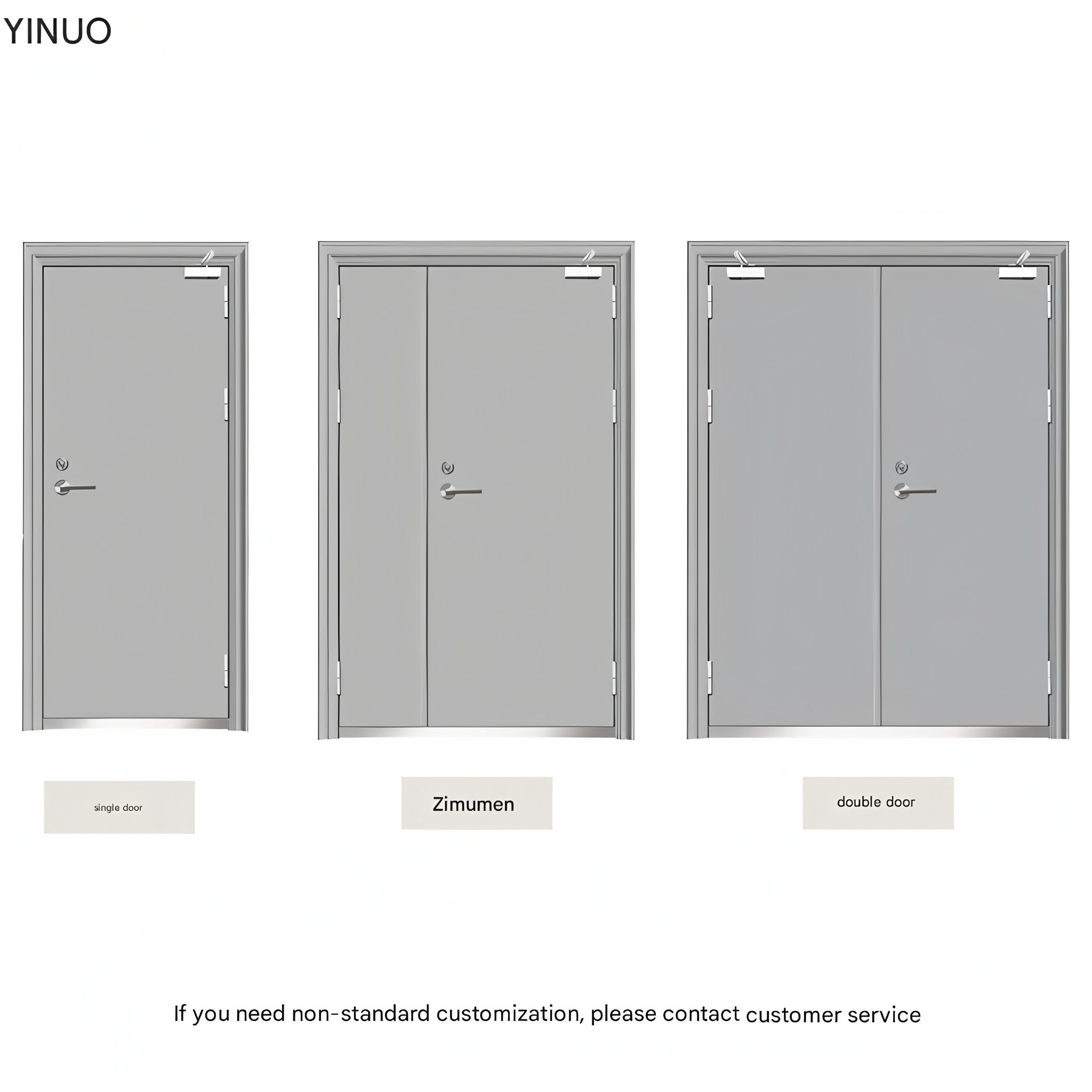

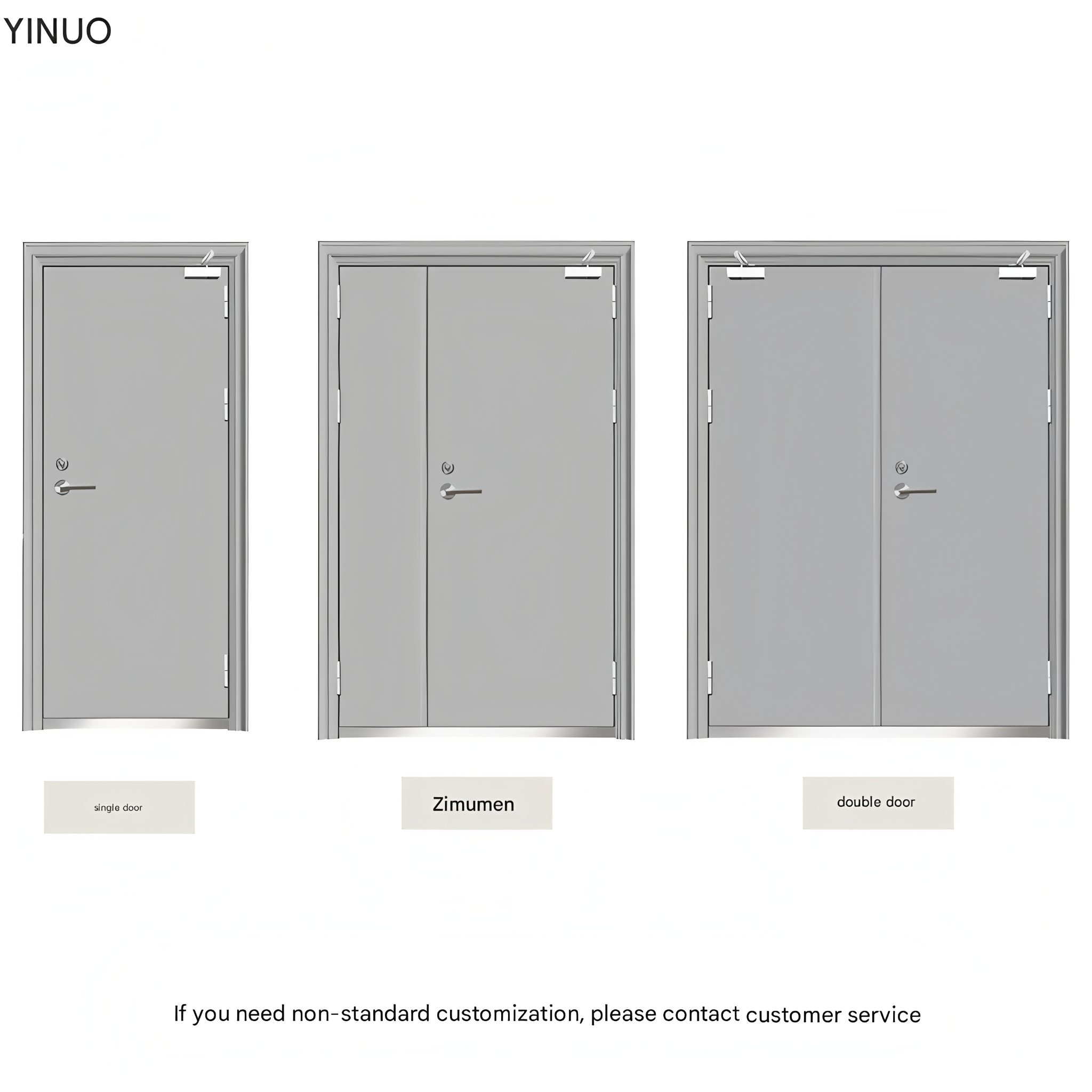

The all-metal construction resists moisture, corrosion, and mold. Routine cleaning requires only simple wiping. Styles and specifications can be customized to meet installation needs in a wide range of settings, including construction projects, shopping malls, office buildings, industrial plants, and residential spaces.

Product Description

This steel fire door is constructed with premium steel plates as the base material, formed through precision stamping, bending, and welding processes. The door leaf is filled with high-density, environmentally friendly fire-resistant core material, ensuring a solid and stable overall structure. Manufactured in strict compliance with national fire safety standards, it provides high-grade fire resistance and thermal insulation. Equipped with high-temperature-resistant intumescent fire seals, the door automatically expands when exposed to flames, sealing gaps to effectively block the spread of fire and smoke, creating a reliable safety barrier for evacuation and rescue operations.

Designed with reinforced frames and leaves, the door offers excellent impact resistance as well as anti-prying and anti-theft properties. It maintains long-term durability with minimal deformation. The product carries comprehensive fire safety certifications, and all performance indicators have passed authoritative testing and verification, ensuring smooth approval in fire safety inspections.

Resistant to moisture and corrosion, easy to clean and maintain, the door can be customized in specifications and styles to meet specific requirements. It is widely suitable for fire compartments and passageways in various buildings, including factories, office buildings, shopping malls, residential complexes, hospitals, and garages. This fire door is an optimal choice that balances safety protection with practical adaptability.

Production Process

Exhibition & Package & Shipping

Product Applications

1. Residential Use

Unit entrance doors, stairwells, fire escape passages, equipment shafts (electrical/power, water, ventilation shafts).

2. Commercial & Office Use

Fire passages in shopping malls/office buildings, shop partitions, equipment/electrical rooms, hotel corridor doors.

3. Industrial & Warehouse Use

Fire compartments in factory buildings, hazardous material storage areas, logistics warehouses, boiler rooms.

4. Public & Institutional Use

School teaching buildings/laboratories, hospital ward areas/operating rooms, archive rooms in government service halls.

5. Transportation & Special Applications

Equipment rooms in subway stations/airports, fire partitions in underground parking garages, partition walls in gas station fuel storage areas.

After-sales Service

1.Free Installation, Commissioning & Training

A professional technical team will provide complimentary on-site installation and commissioning of the door and its control system to ensure all operational parameters meet usage standards. One-on-one training will also be conducted for facility and equipment management teams, covering daily start/stop, linkage setup, basic troubleshooting, and other relevant content. Operation manuals and maintenance guides will be provided.

2.Extended Warranty & Quick Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire unit is covered by a 1-year warranty. During the warranty period, repairs and parts replacement for non-human-induced failures are provided free of charge.

3.Regular Inspection & Preventive Maintenance

During the warranty period, technicians will perform on-site inspections every 6 months to evaluate door sealing performance, sensor sensitivity, motor operation, and other key aspects. Aging or vulnerable parts (such as brush seals) will be replaced in a timely manner to prevent potential malfunctions. After the warranty expires, customers can sign an annual maintenance agreement to enjoy discounted inspections and priority repair services, thereby extending the door's service life.

4.Sufficient Spare Parts Inventory

We maintain an adequate inventory of spare parts to ensure timely supply for repairs and replacements.

5.Lifetime Technical Support & Upgrade Service

Lifetime free technical consultation is provided to answer any questions that may arise during use. Should upgrades to the door linkage function be needed in the future—such as integration with new access control or fire protection systems—cost-based technical upgrade services are available to meet the needs of smart facility upgrades, such as those in hospitals.

FAQS

1. Q: What is the difference between normally open and normally closed steel fire doors?

A: Normally closed doors are equipped with door closers and remain shut under normal conditions, automatically sealing to block smoke during a fire. Normally open doors feature electromagnetic releases, closers, and signal feedback devices—they stay open for easy passage in daily use and are designed to close automatically upon power cut-off when triggered by a fire alarm. This design is suitable for high-traffic public passageways.

2. Q: How can you identify low-quality steel fire doors?

A: Check whether 3C certification and test reports are complete; verify that the steel plate thickness meets standards; tap the door leaf to listen for solid filling (no hollow sound); inspect whether components such as locks and hinges are fire-rated; and be cautious of products that are unusually low in price or lack proper labeling.

3. Q: What should be noted when replacing parts?

A: Only fire-certified dedicated parts (such as fire-rated locks, hinges, and door closers) must be used. Ordinary parts cannot withstand high temperatures and may fail rapidly in a fire, compromising the door's protective function.

4. Q: What is the expected service life under normal use?

A: Properly maintained, qualified products in dry environments typically last 10-15 years. In humid or high-frequency use scenarios, the lifespan is about 7-10 years. In high-temperature or corrosive environments without anti-corrosion treatment, service life may be reduced to 5-8 years. After a fire, the door must be replaced regardless of its outward appearance.

5. Q: How can daily maintenance help preserve performance?

A: Weekly: Check that closers, locks, and hinges operate smoothly. Monthly: Clean the surface with water or mild soap solution (avoid corrosive cleaners). Quarterly: Apply lubricant to hinges and moving parts of door closers. Annually: Test signal feedback and linkage functions with fire-alarm systems. Never lock, block, or remove any safety components.

Procurement advantages

1.Cold-rolled steel plates + premium fire-resistant core material – impact-resistant, deformation-resistant, and corrosion-resistant, suitable for various environments.

2.Standard fire-rated hardware – low failure rate, with a lifespan of 10-15 years under normal conditions.

3.Cost-effective at the same fire rating – bulk purchase discounts available, ensuring low procurement costs.

4.Standardized production and easy installation – simple long-term maintenance, with full lifecycle cost control.

5.Wide application coverage – suitable for residential, commercial, industrial, transportation, and other scenarios, meeting diverse installation needs.

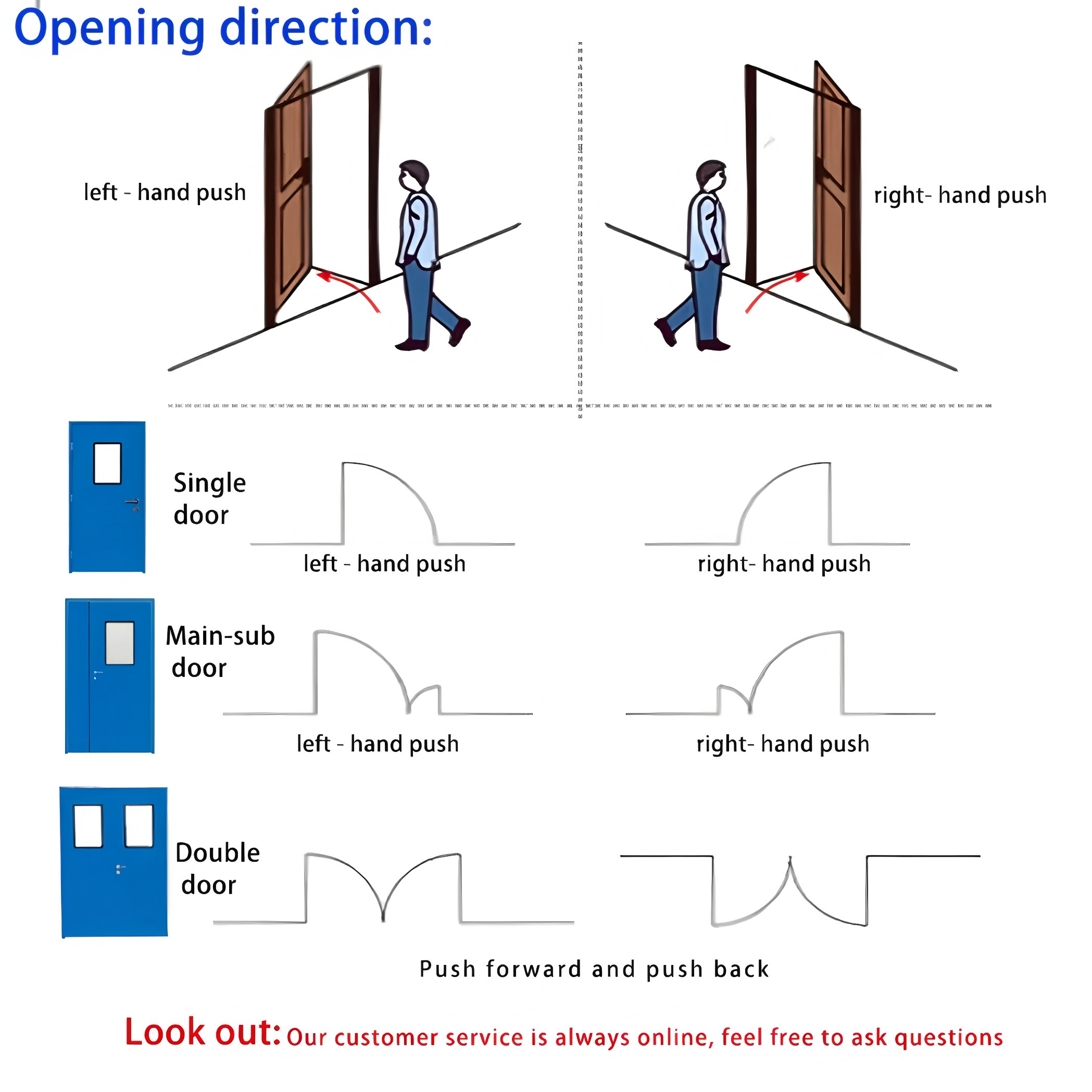

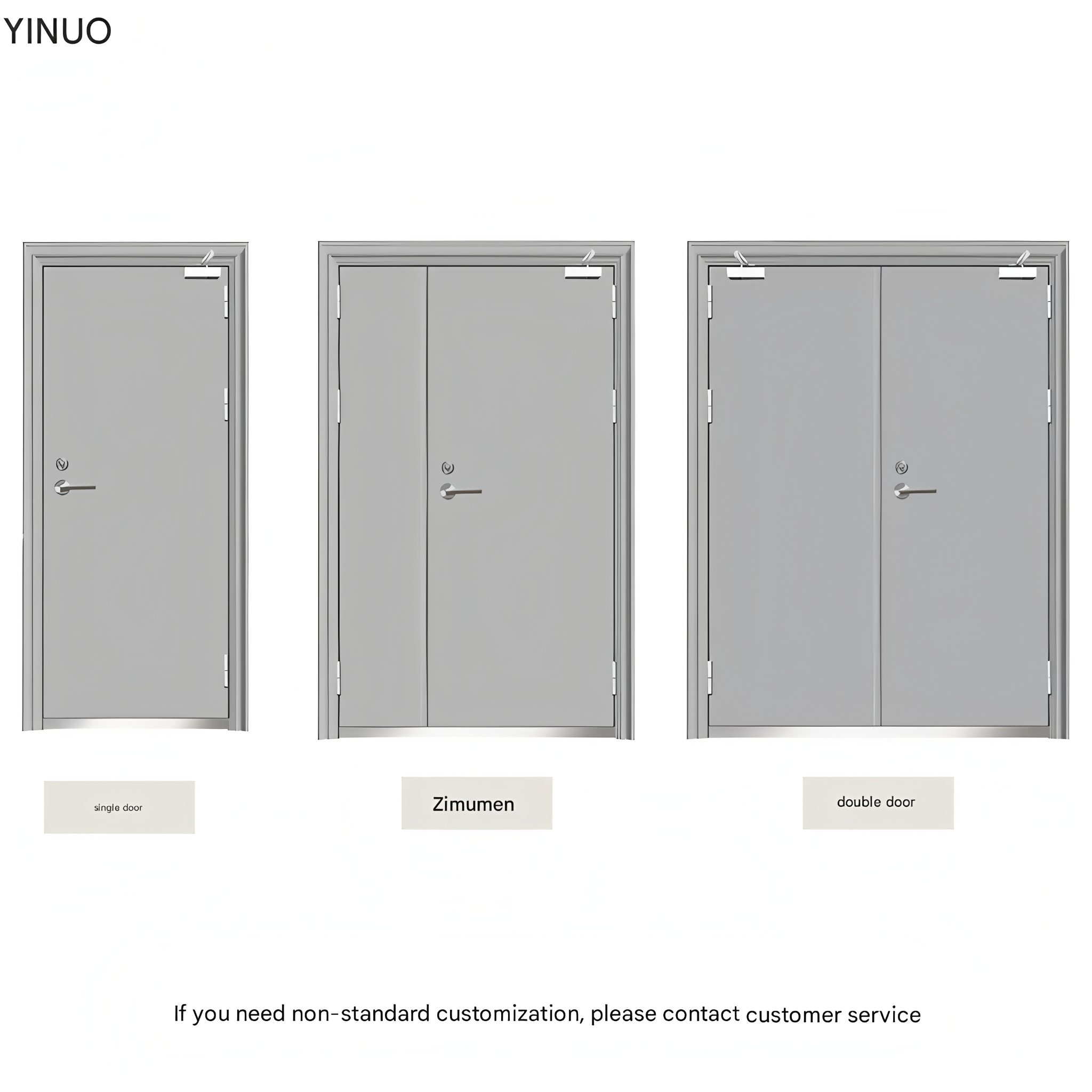

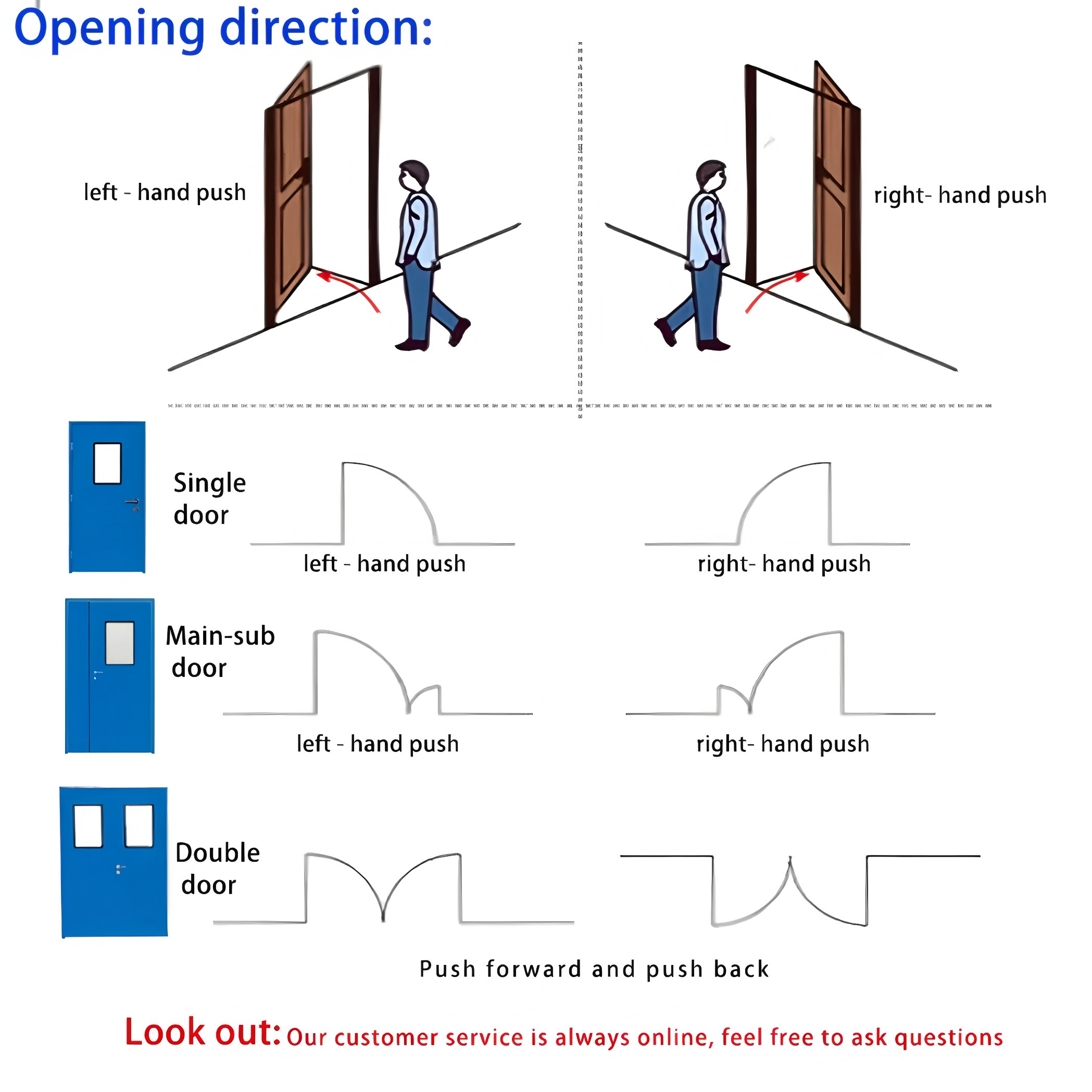

6.Customizable size, opening direction, and color – supports additional features such as fire-resistant glass installation.

7.Mature supply chain and sufficient production capacity – standard products delivered in 7-15 days, ensuring timely project completion.

8.Reputable manufacturer providing installation guidance and warranty service – products are traceable, ensuring worry-free procurement.