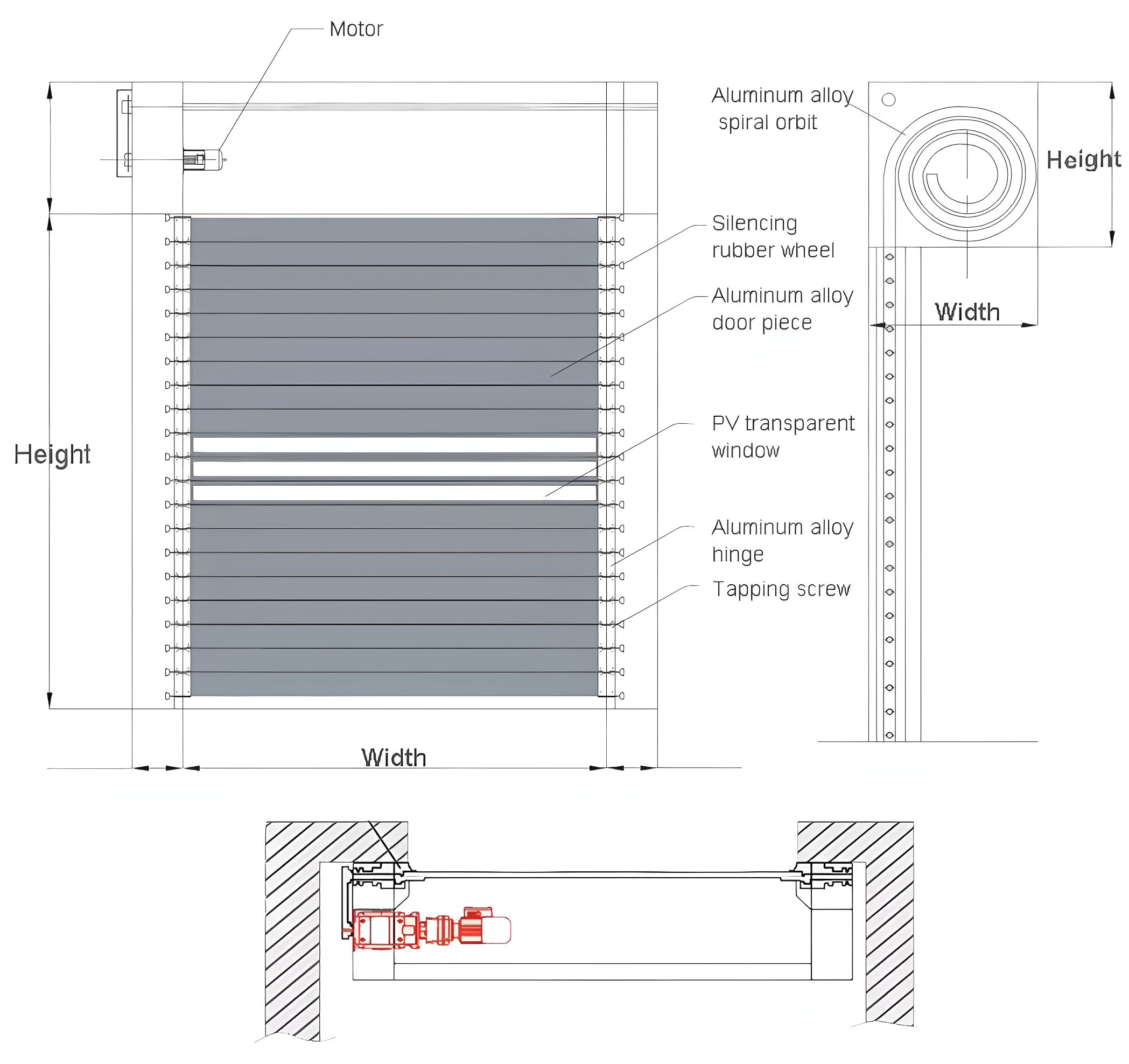

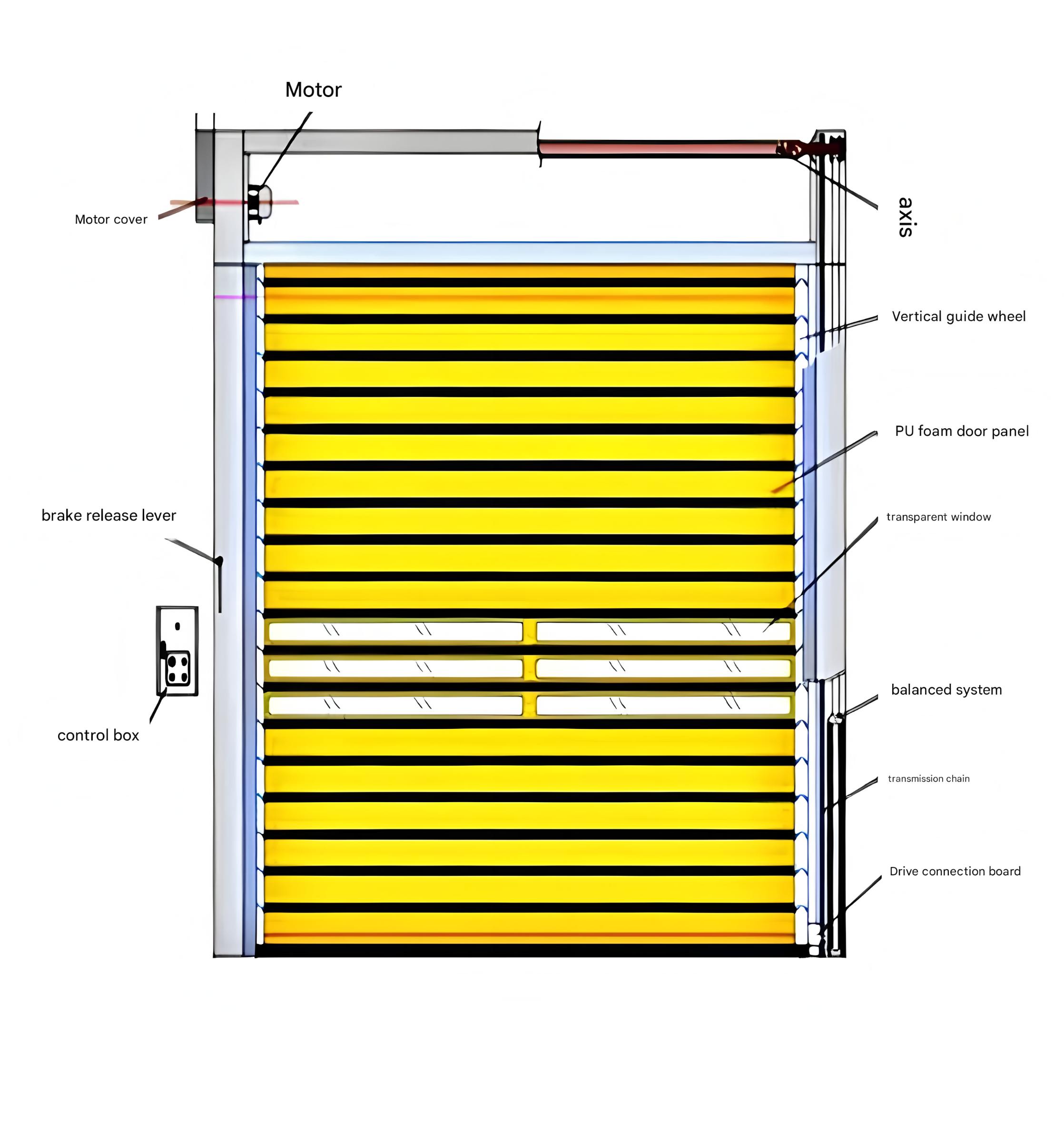

Product Feature

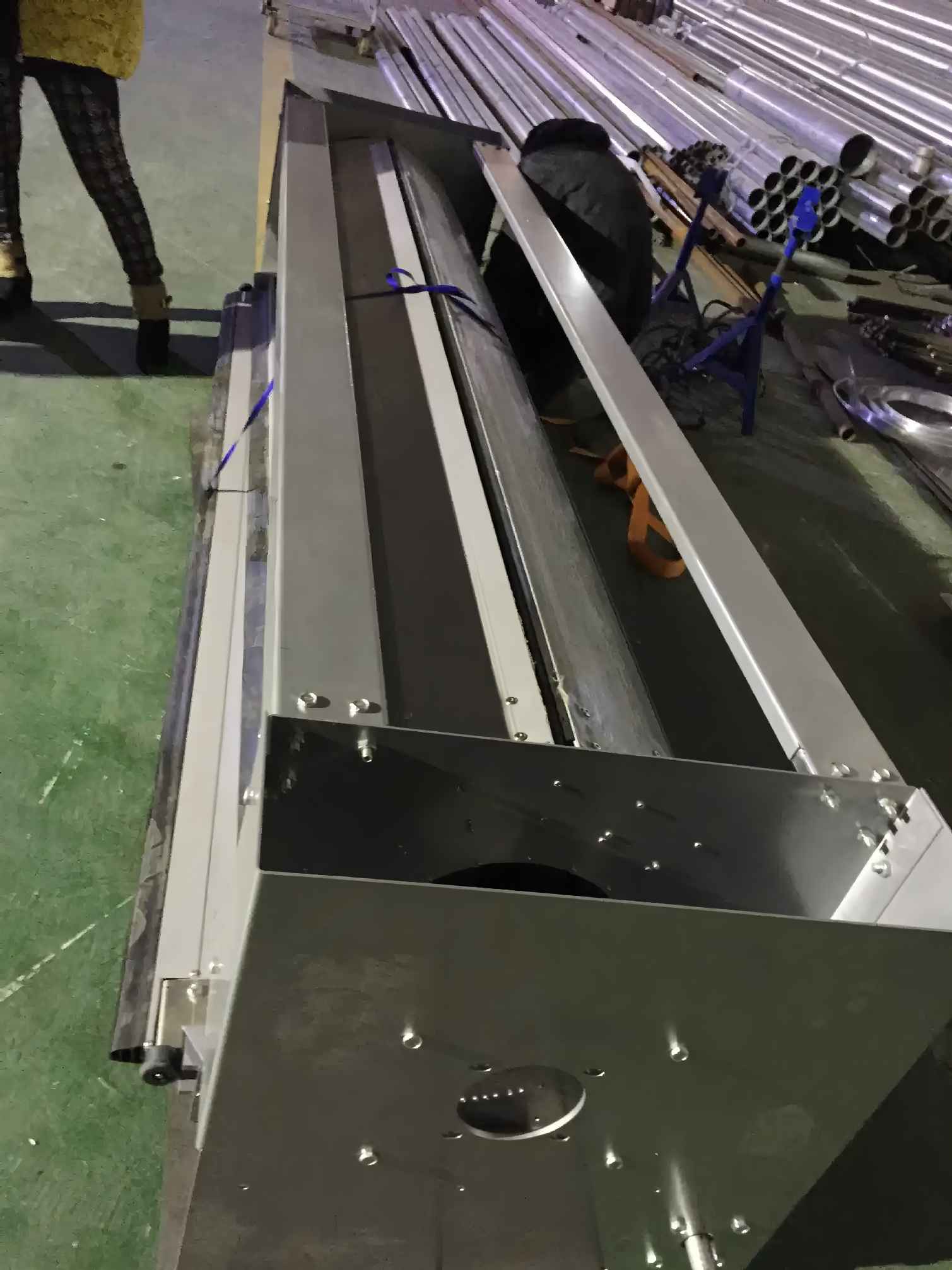

1.High Speed & High Frequency, Max Efficiency

Opening/closing speed reaches 1-2.35 m/s, enabling a 4-meter door to fully open in just 2 seconds. Capable of over 1,800 daily cycles and compatible with automatic sensor linkage, significantly reducing passage wait times.

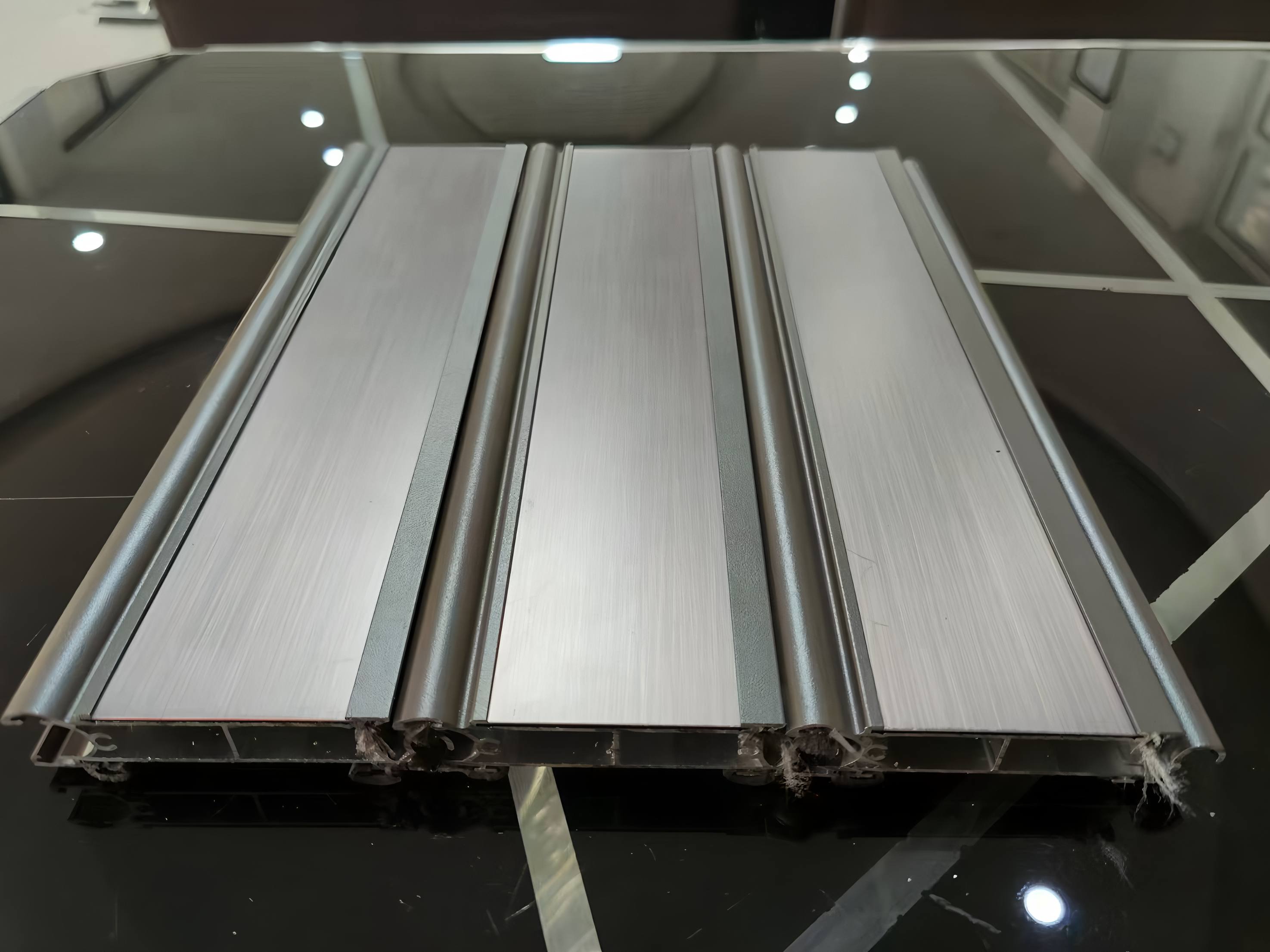

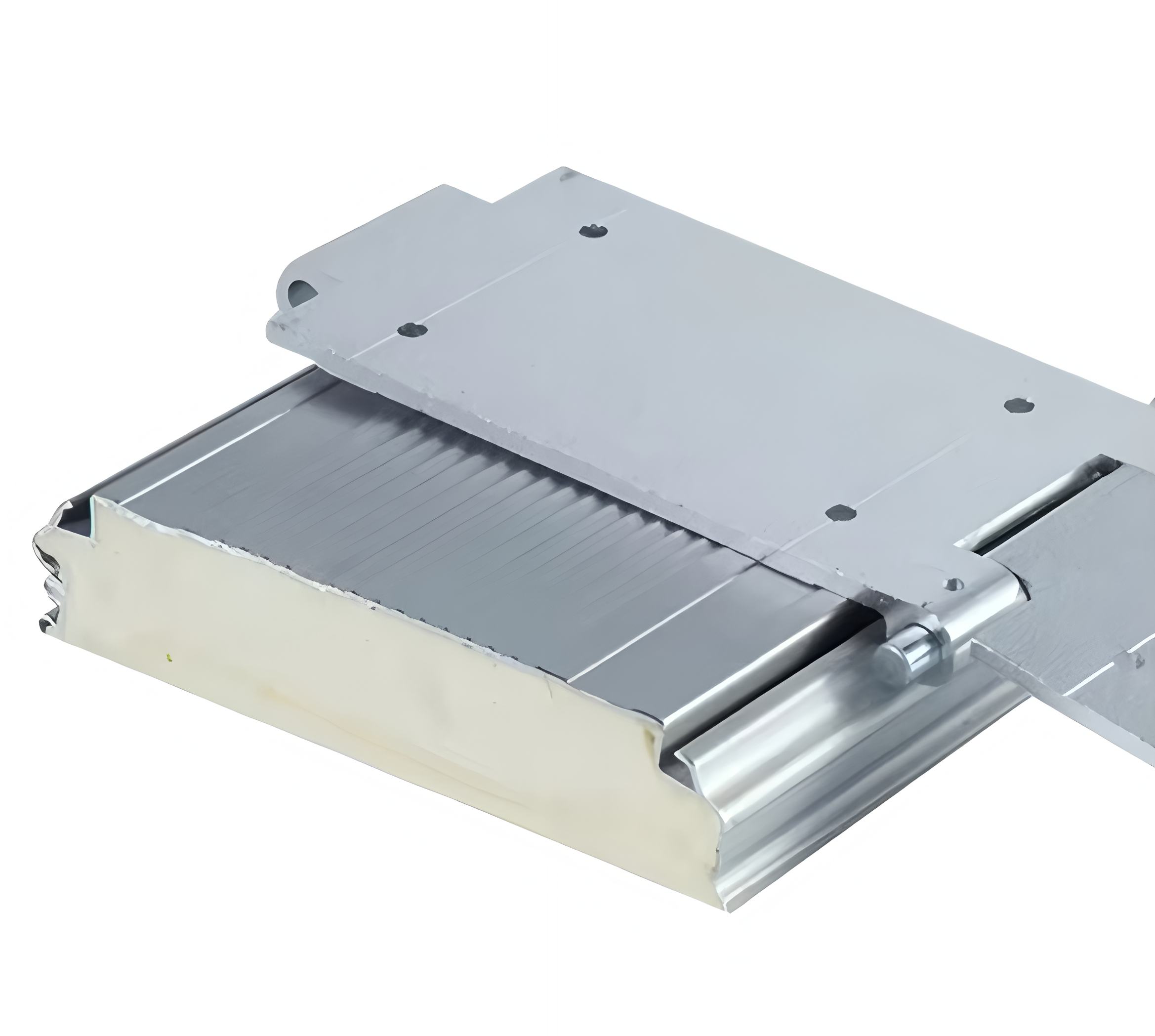

2.Sealed & Insulated, Energy-Saving

Quadruple sealing (sides, bottom, top, between panels) combined with polyurethane foam panels (K-value 0.4 W/㎡·K) effectively blocks dust and odors while reducing energy consumption in cold storage and climate-controlled workshops.

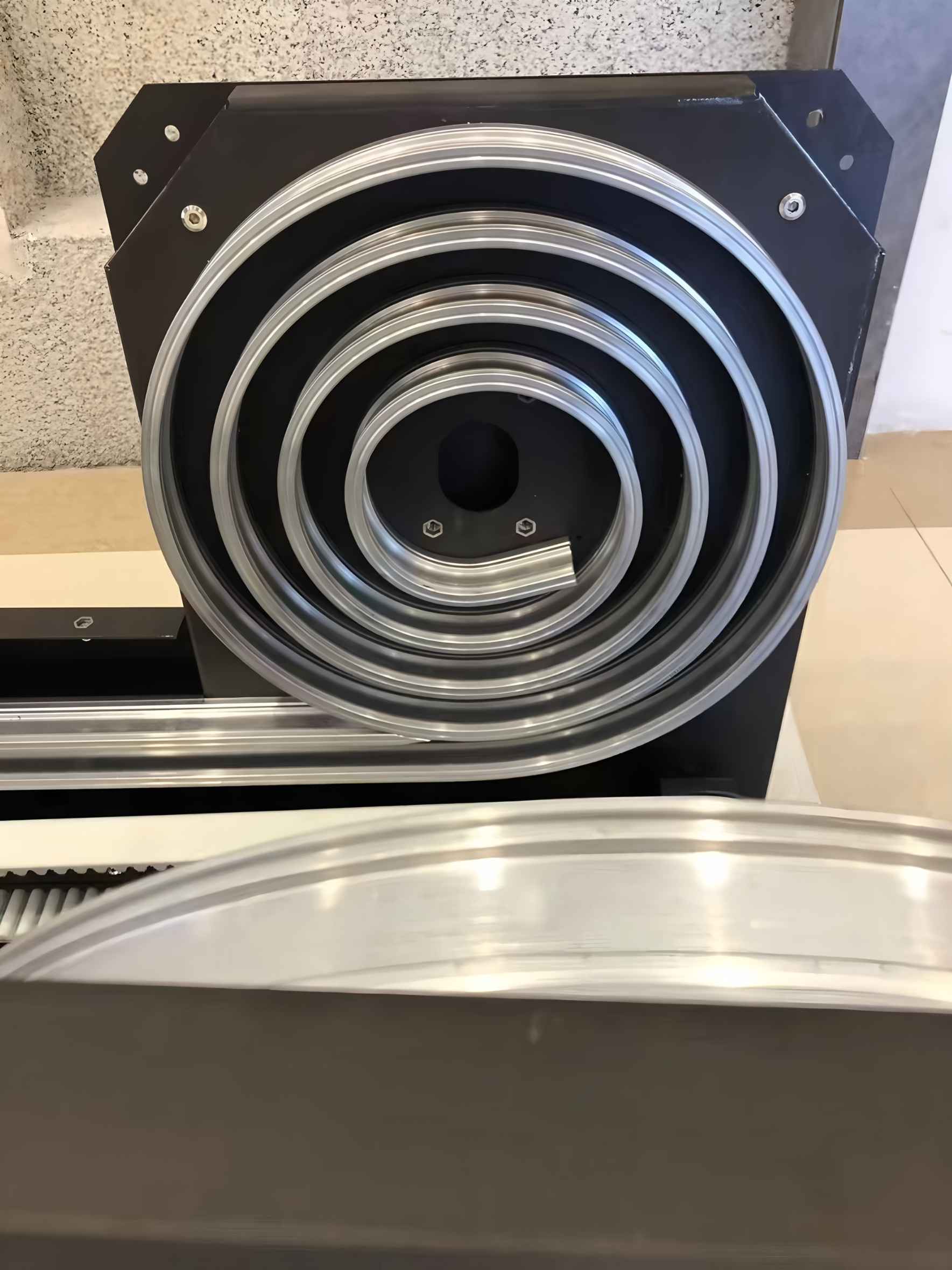

3.Wind-Resistant & Durable, Environmentally Adaptive

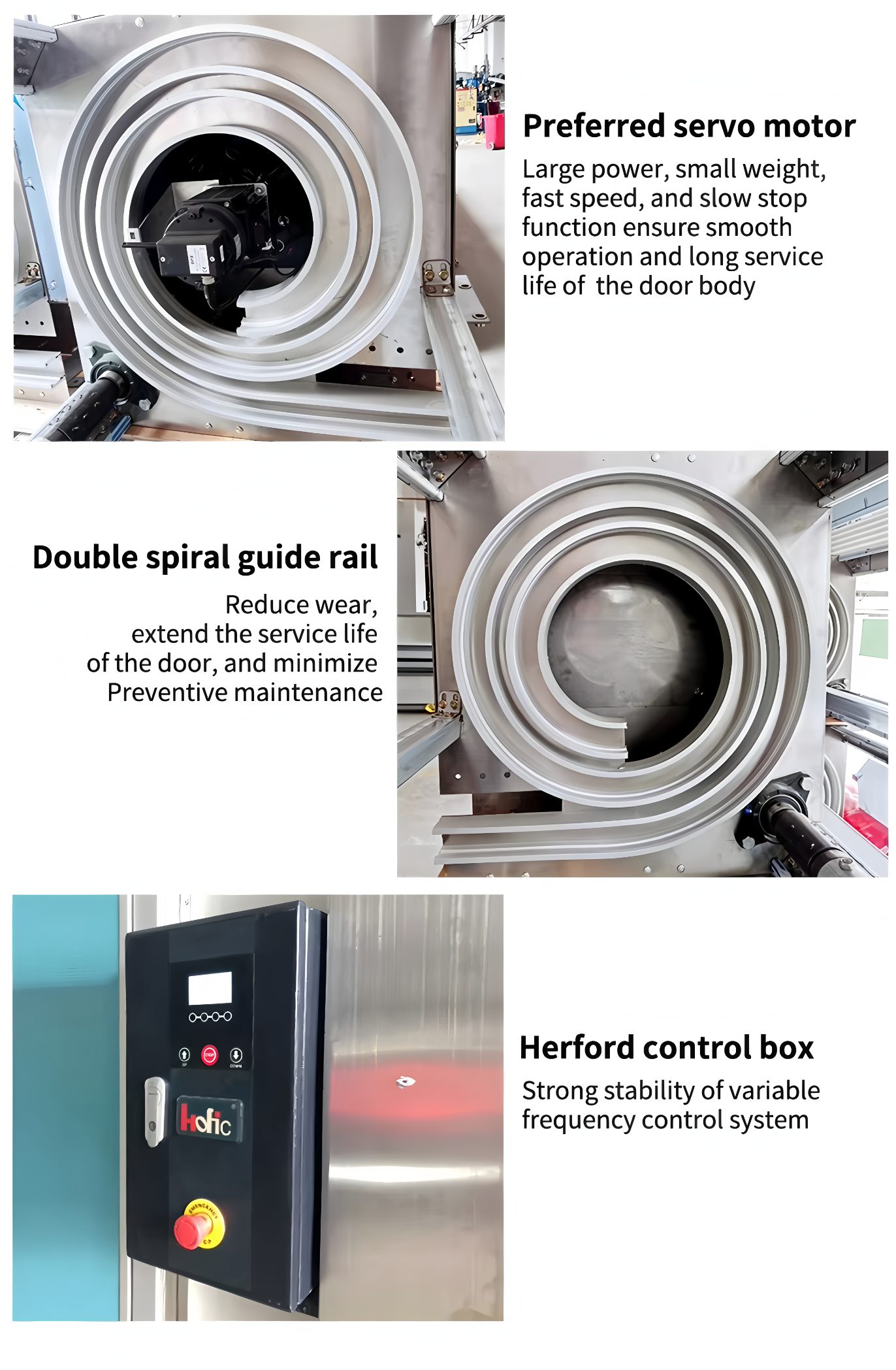

Turbo track + aluminum alloy panel structure withstands wind loads up to levels 11–12, operates across temperatures from -30°C to 70°C, and requires minimal maintenance even after millions of cycles—ideal for coastal or high wind-pressure locations.

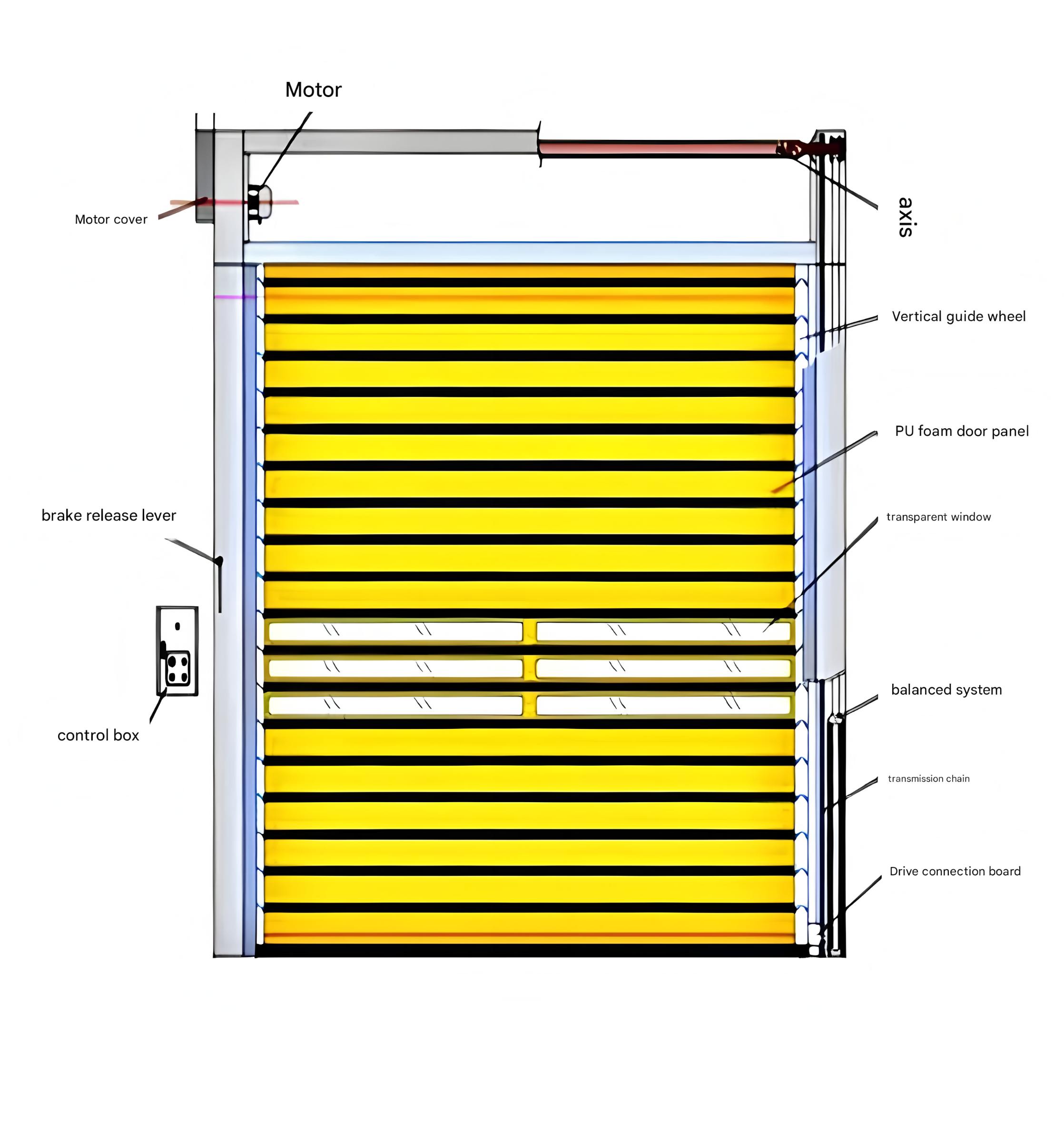

4.Safe & Intelligent, Comprehensive Protection

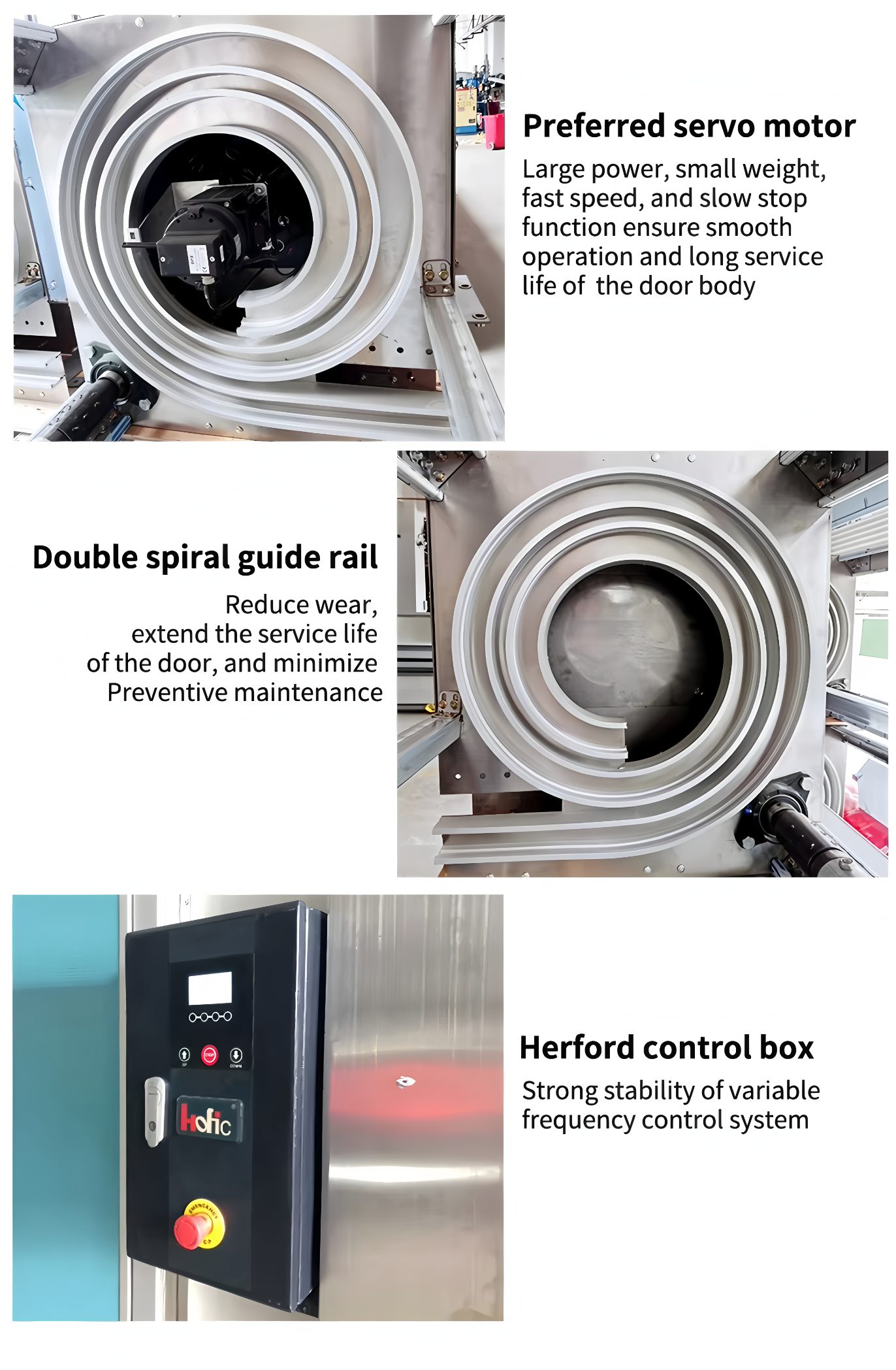

Equipped with photoelectric sensors and safety edges for automatic bounce-back upon obstacle detection. Servo motor + frequency conversion control supports remote linkage and preset opening heights, with manual emergency operation available during power outages.

5.Low Noise & Low Energy Consumption, Stable Operation

Turbo frictionless track + polyurethane wheel sets ensure quiet operation. The thermal break door panel design balances strength and insulation for lower long-term usage costs.

Product Description

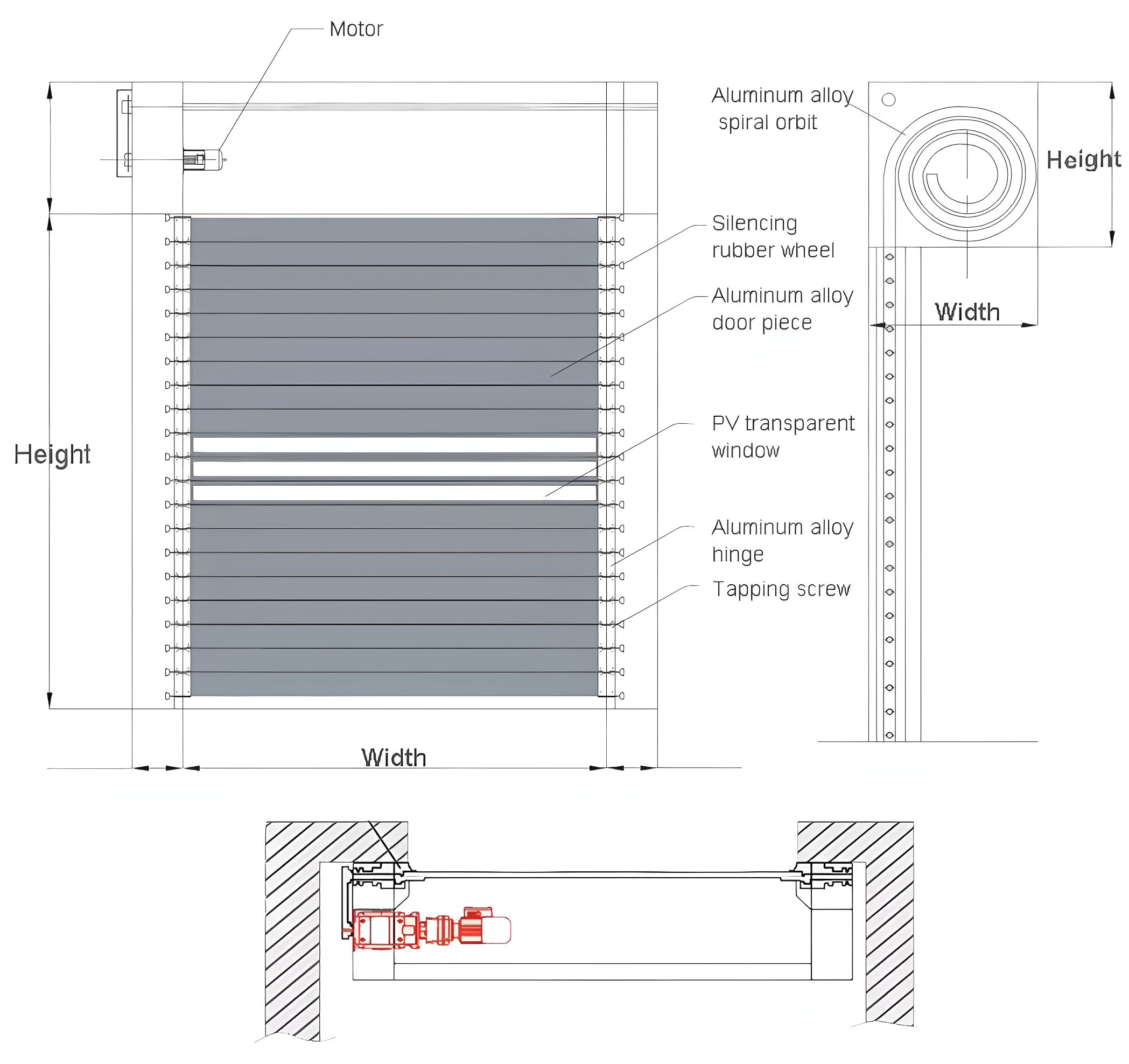

Turbo Hard Rapid Door is the flagship model in the industrial hard rapid door series. It features rigid aluminum alloy polyurethane foam door panels and a turbine-style guide rail drive system, enabling fast, smooth, and quiet opening and closing operations. The product offers excellent wind resistance and outstanding sealing and insulation performance, effectively preventing dust and insects, isolating temperature variations and odors, and significantly reducing energy consumption. Equipped with multiple safety protections, it automatically stops and reverses upon encountering obstacles and supports various sensor-based activation methods. Designed for high-frequency use, it boasts a sturdy and durable structure with low long-term maintenance costs. Widely applicable in industrial workshops, logistics passages, loading and unloading areas, garages, and other scenarios, it efficiently meets both access and security needs with strong practicality.

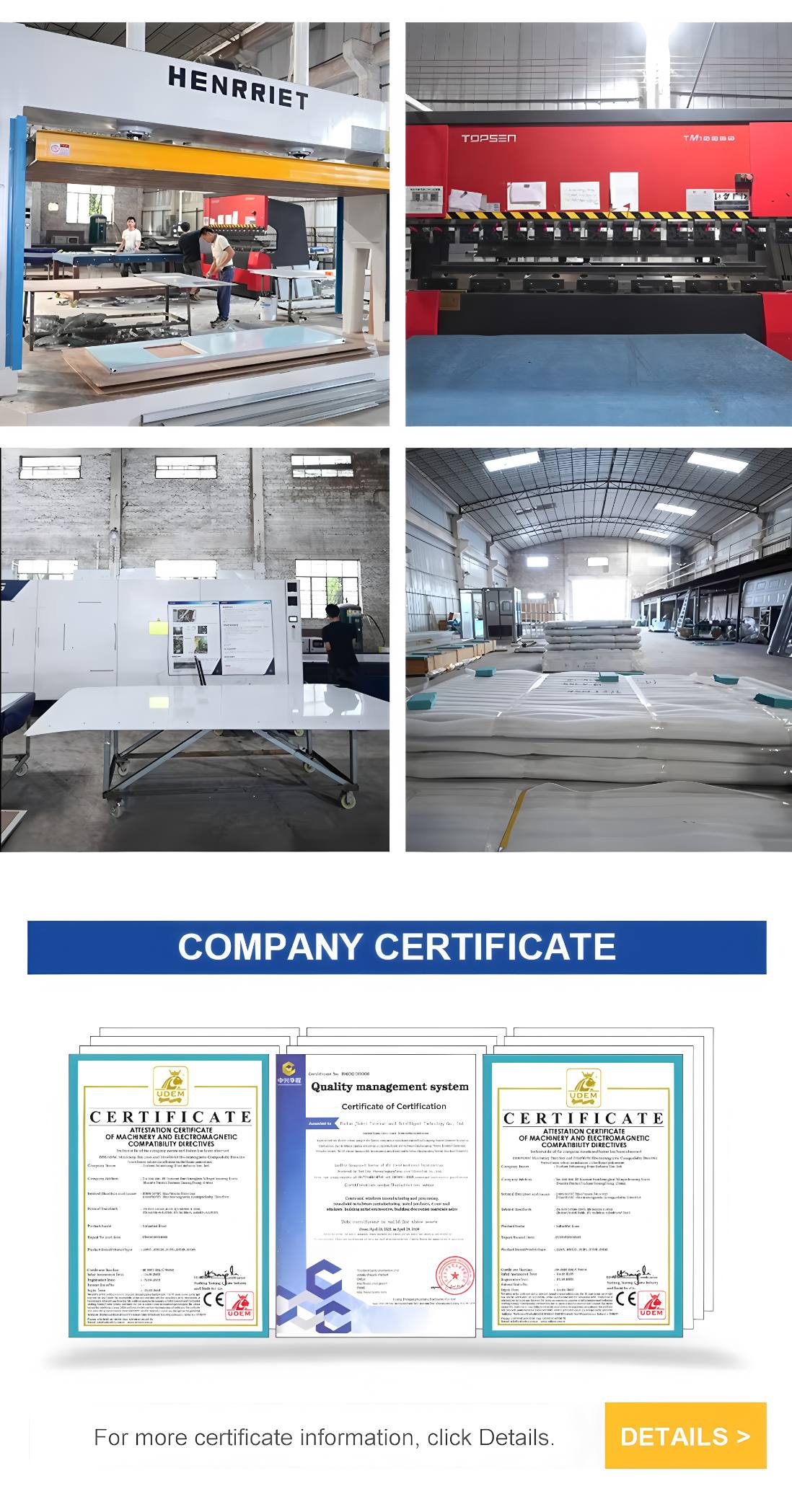

Production Process

Exhibition & Package & Shipping

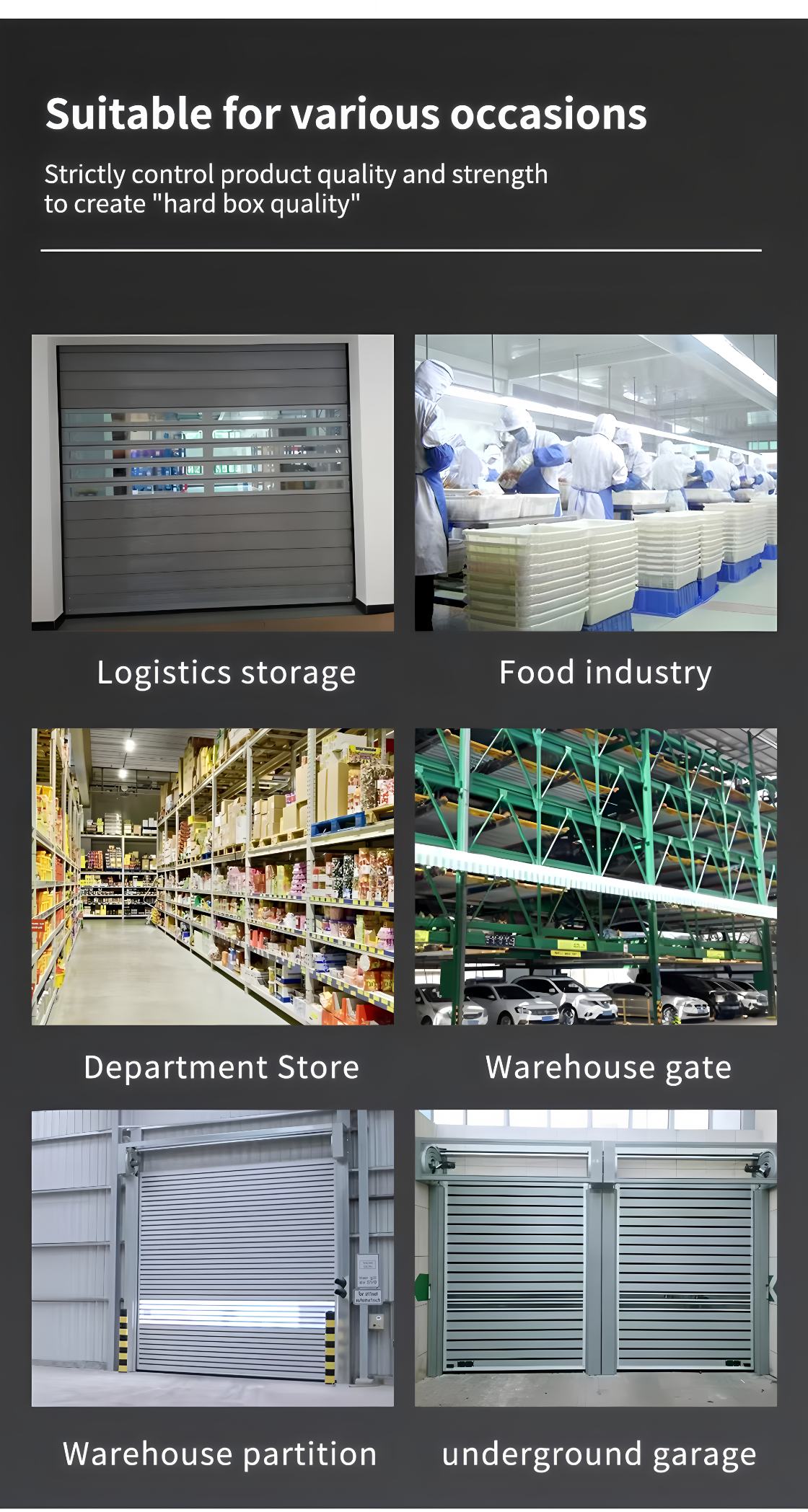

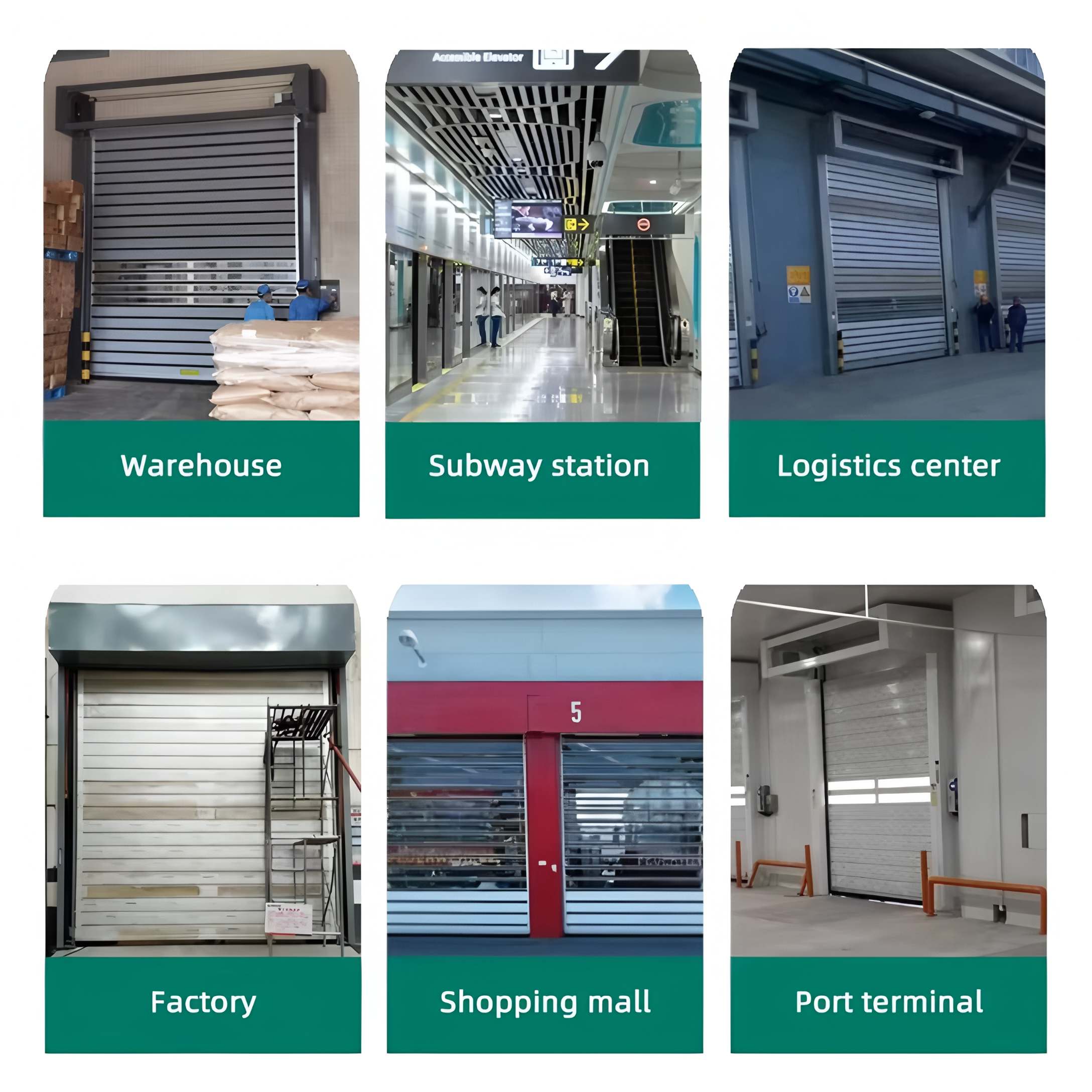

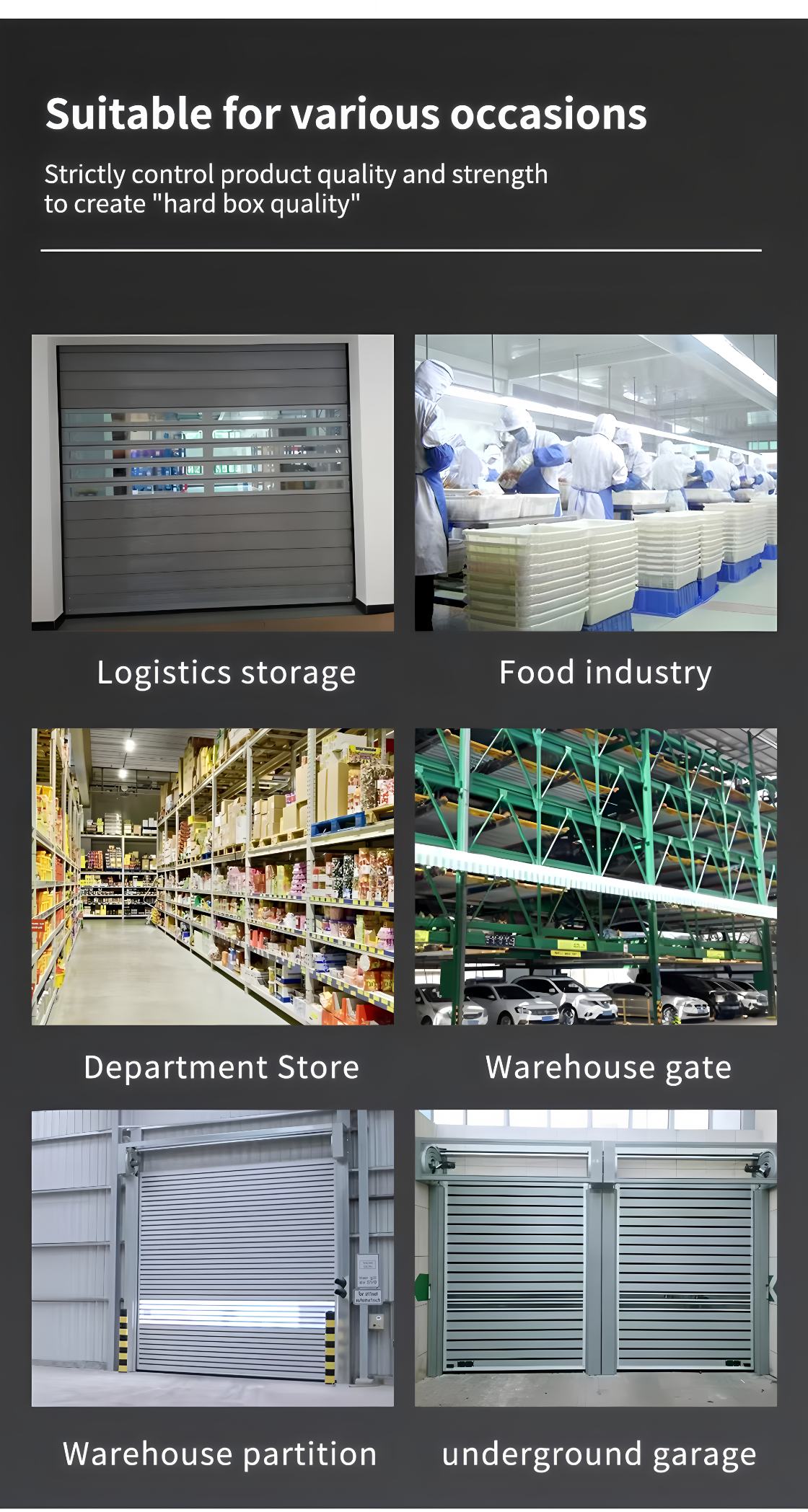

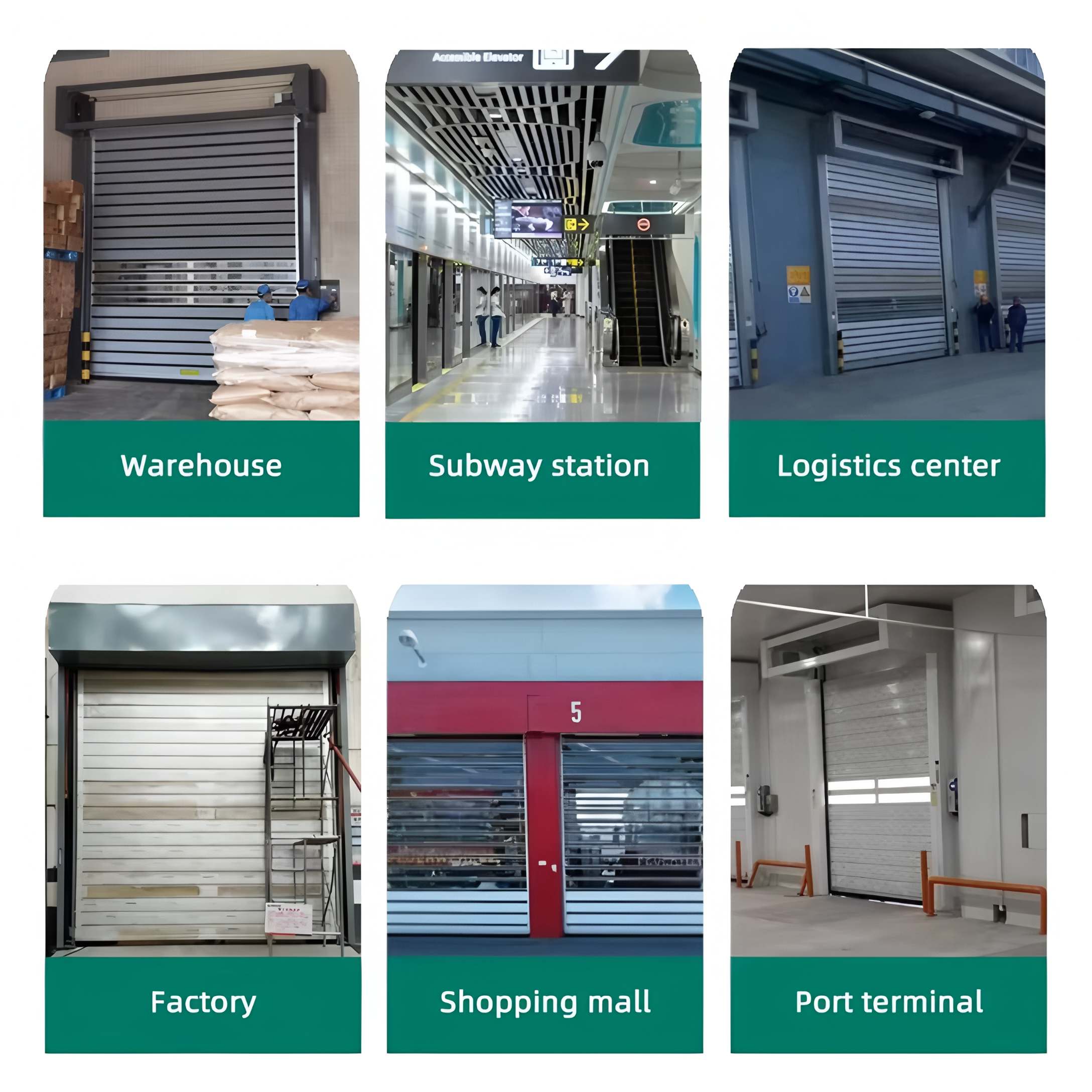

Product Applications

1.Various Industrial Plants and Production Workshops

Main workshop passages and material transfer openings, meeting high-frequency opening and closing needs to improve production and traffic efficiency.

2.Warehousing and Logistics Centers, Cold Storage Facilities

Access passages for ambient or cold storage areas, providing sealing, insulation, and thermal barrier effects to prevent dust and odors, while reducing energy consumption and loss.

3.Parking Garages in Industrial Parks/Factory Areas and Underground Parking Lots

Dedicated to vehicle entry and exit points, fast opening and closing reduces vehicle waiting time, with wind-resistant durability suitable for outdoor environments.

4.Loading and Unloading Platforms, Logistics Docking Areas

Suitable for frequent truck entry and exit, isolating outdoor dust and temperature variations to maintain a clean storage environment.

5.Cleanrooms for Electronics, Automotive Parts, and Chemical Industries

Entrances and exits of dust-free and precision machining workshops, offering dustproof sealing to meet the requirements of clean production environments.

6.Coastal and High Wind-Pressure, Dust-Prone Industrial Areas

High wind resistance rating, suitable for harsh weather conditions, providing excellent wind and dust protection with long-term durability.

After-sales Service

1.Free Installation, Commissioning, and Training

A professional technical team will provide free on-site installation and commissioning of the door body and control system, ensuring all operating parameters meet usage standards. Additionally, one-on-one operational training will be offered to logistics and equipment management teams, covering daily start-stop procedures, linkage settings, simple troubleshooting, and more. Operation manuals and maintenance guides will also be provided.

2.Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire machine is covered by a 1-year warranty. During the warranty period, non-human damage faults will be repaired free of charge, and replacement parts will be provided at no cost.

3.Regular Inspections and Preventive Maintenance

During the warranty period, technical personnel will conduct on-site inspections every 6 months to check the door body’s sealing performance, sensor sensitivity, motor operation status, and other aspects. Worn-out components (e.g., brush seals) will be promptly replaced to prevent potential faults. After the warranty period ends, customers can sign an annual maintenance agreement to enjoy discounted inspection services and priority repairs, extending the service life of the door body.

4.Adequate Spare Parts Inventory

Ensures timely supply of maintenance parts.

5.Lifetime Technical Support and Upgrade Services

Lifetime free technical consultation is provided to address various issues encountered during use. If upgrades to the door body’s linkage functions are required in the future (e.g., integration with new access control or fire protection systems), cost-price technical upgrade services are available to meet the hospital’s intelligent renovation needs.

FAQS

Q:What is the opening and closing speed of the turbo hard rapid door? Is it prone to failure under high-frequency use?

A: The standard operating speed is 1.0–2.35 m/s, allowing a 4-meter-high door to fully open in just 2–3 seconds. With its frictionless turbo track and rigid aluminum alloy panels, the door is designed for durability and can handle over 1,800 daily cycles. It offers low long-term failure rates and exceptional stability.

Q:How effective is the wind resistance of this door? Is it suitable for coastal areas?

A: Strong wind resistance is a core advantage of the turbo hard rapid door. Combined with a turbo guide track and thickened rigid panels, it achieves a wind resistance rating of up to levels 11–12. This makes it fully suitable for coastal regions with high wind pressure, frequent typhoons, and dusty conditions, ensuring reliable outdoor performance.

Q:Does the turbo hard rapid door provide good insulation and sealing?

A: The door consists of aluminum alloy panels filled with high-density polyurethane foam and features a quadruple sealing system (top, side, bottom, and inter-panel seals). It delivers excellent sealing to effectively block dust, odors, and thermal exchange while offering strong thermal insulation. This helps reduce energy consumption in workshops or cold storage facilities, making it ideal for temperature-controlled environments such as constant-temperature workshops and cold chain logistics.

Q:What safety features does the door have when encountering obstacles during operation? What happens in a power outage?

A: The door is equipped with dual safety protection, including obstacle detection auto-reverse and photoelectric sensors. If the door comes into contact with a person or object during operation, it immediately stops and reverses to prevent injury risks. It also includes an emergency manual mechanism for power outages, allowing easy manual operation to ensure uninterrupted access during emergencies.

Q:What is the difference between a turbo track and a regular track? Is maintenance complicated?

A: The turbo track uses a frictionless guide structure, ensuring smoother and quieter operation with no track wear. It has a significantly longer service life compared to regular tracks. The door has minimal wearable parts, and daily maintenance simply involves cleaning the track and inspecting the sealing strips, requiring no professional expertise. This results in very low long-term maintenance costs.

Q:What types of activation methods does this door support, and does it meet industrial requirements?

A: The door supports multiple activation methods, including radar sensors, ground sensors, pull-cord switches, and remote controls. It can also be integrated with PLC control systems and preset opening heights, making it suitable for industrial workshops, logistics passages, loading/unloading areas, and other scenarios with frequent forklift or truck traffic. It fully meets the demands of high-frequency industrial access.

Q:What is the operating temperature range of the turbo hard rapid door? Will low temperatures affect its performance?

A: The door is highly weather-resistant, with an operating temperature range of -30°C to 70°C. It functions reliably in both low-temperature cold storage and high-temperature workshops. All hardware components and the motor are treated to withstand extreme temperatures, ensuring smooth operation without jamming or failure.

Procurement advantages

1.Efficiency Improvement, Cost Reduction & Revenue Growth

With an opening/closing speed of 1–2.35 m/s, a 4-meter door fully opens in just 2 seconds. Capable of over 1,800 daily cycles, it minimizes vehicle and personnel waiting time, enhances logistics and production efficiency, and accelerates supply chain flow.

2.Strong Wind Resistance & Durability, Wide Applicability

Featuring a turbo track and 40mm aluminum alloy polyurethane foam panels, the door withstands wind loads up to levels 11–12 and operates in temperatures from -30°C to 70°C. Designed for millions of cycles with low failure rates, individual panels can be replaced independently, ensuring more economical maintenance.

3.Excellent Sealing & Insulation, Significant Energy Savings

Equipped with quadruple sealing and high-density polyurethane foam (K-value: 0.4 W/㎡·K), the door effectively blocks dust and odors while reducing energy consumption in cold storage and climate-controlled workshops by over 30%. This results in lower long-term operational costs.

4.Comprehensive Safety, Compliance Assurance

Standard features include photoelectric sensors and safety edges, with automatic bounce-back within 0.3 seconds upon obstacle detection. Manual emergency operation is available during power outages, and the door supports integration with PLC/AGV systems, meeting industrial safety standards and intelligent management requirements.

5.Low Noise & Energy Consumption, Stable Long-Term Performance

The frictionless turbo track and polyurethane wheel sets keep operational noise below 65 dB. Powered by servo frequency conversion drive, the door consumes minimal energy, with long-term maintenance costs up to 67% lower than traditional doors.

6.Flexible Customization, High Adaptability

Supports non-standard customization for widths up to 10 meters, compatible with radar, ground sensors, remote controls, and other activation methods. Ideal for diverse applications such as factories, cold chains, garages, and cleanrooms.

7.Easy Maintenance, Universal Parts

Modular design minimizes wearable parts, and the track requires no lubrication. Daily maintenance only involves cleaning sealing strips and inspecting the track. Universal parts ensure quick replacement and low costs.

8.Smart Integration & Upgrade Compatibility

Supports preset opening heights, remote monitoring, and multi-door linkage. Can be integrated with ERP/MES systems to support Industry 4.0 and automation upgrades.

9.Optimized Lifecycle Cost

Although the initial purchase cost is higher than conventional doors, the extended lifespan, low energy consumption, and minimal maintenance result in lower total costs within 2–3 years, delivering higher long-term returns.