Product Feature

1. Automatic Self-Healing Reset, Anti-Collision and Durable

Adopts zipper-style or dedicated guide rail design; if the door curtain is impacted and derails, it can automatically reset during the next operating cycle without manual intervention, significantly reducing downtime, maintenance time, and costs—ideal for frequent operation scenarios involving forklifts.

2. High-Speed Opening and Closing, Enhancing Efficiency

Opening speed up to 0.8-2 m/s, enabling rapid isolation of areas during high-frequency passage, reducing cold/hot air exchange and dust ingress while ensuring efficient throughput in logistics, production, and other processes.

3. Superior Sealing and Insulation, Energy-Saving and Environmentally Friendly

Door curtain edges equipped with EPDM rubber strips or zipper sealing structure, with an elastic sealing device at the bottom to tightly fit the door frame and ground, effectively blocking heat loss, dust, and odors, thereby reducing energy consumption for air conditioning or heating.

4. Multiple Safety Features, Reliable Operation

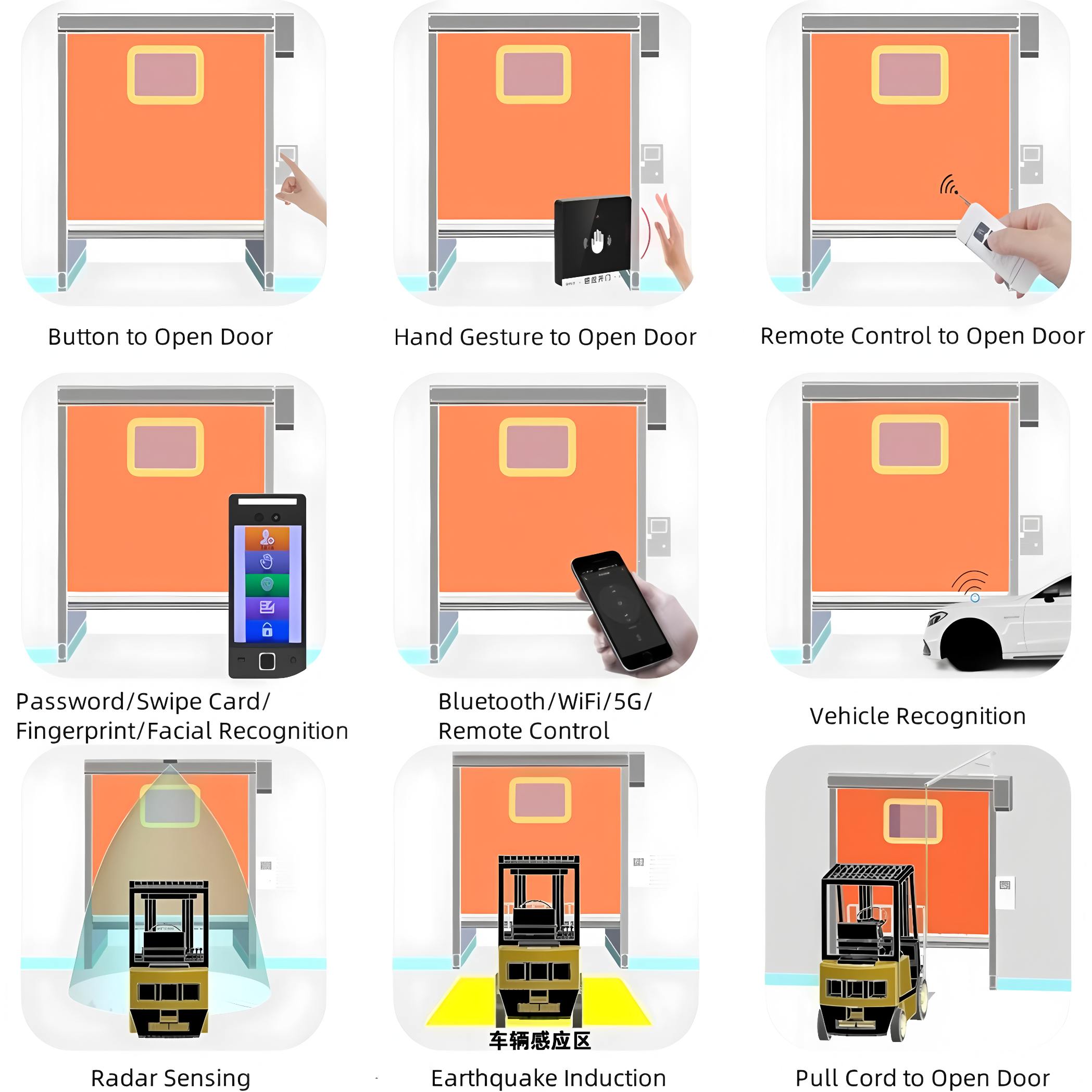

Standard configuration includes photoelectric sensors, wireless safety edges, soft bottom edges, etc.; the door automatically stops or reverses upon encountering obstacles. The curtain has no hard metal components, minimizing damage upon impact and ensuring safety for personnel and vehicles.

5. Low Consumption and Durable, Easy Maintenance

Door curtain primarily made of high-strength polyester fiber with PVC coating, offering excellent wear resistance, tear resistance, and weatherability. Modular structural design allows easy component replacement; standard service life exceeds 1 million cycles, resulting in low long-term operating costs.

Product Description

The self-healing high-speed door is the preferred solution for high-frequency passage scenarios in industrial logistics.

Its core advantage lies in automatic reset after impact: if the door curtain is derailed by external forces such as forklifts, it can autonomously return to position without manual repair, significantly reducing downtime and associated losses. The door opens and closes at speeds of 0.8-2 m/s, efficiently isolating the internal and external workshop environments. Combined with a full-perimeter sealing structure, it effectively prevents dust, provides thermal insulation, and promotes energy savings.

It is also equipped with multiple safety features, including photoelectric sensors and soft safety edges, ensuring the safety of personnel and vehicles. The door curtain is made of wear-resistant PVC-coated material with a modular design for easy maintenance and a service life exceeding 1 million cycles. It is suitable for a wide range of industrial applications, including warehousing, cold chain logistics, and clean workshops.

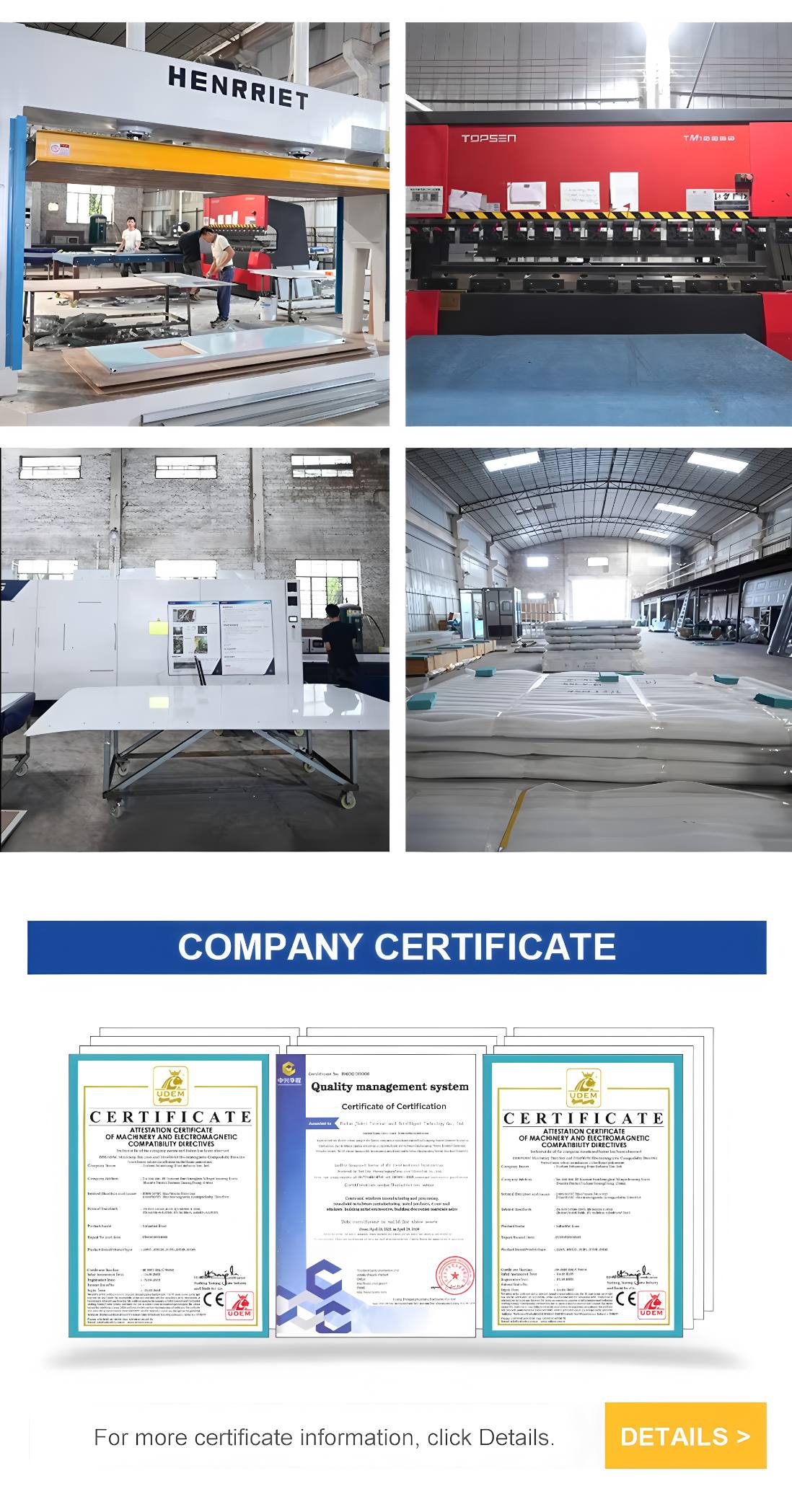

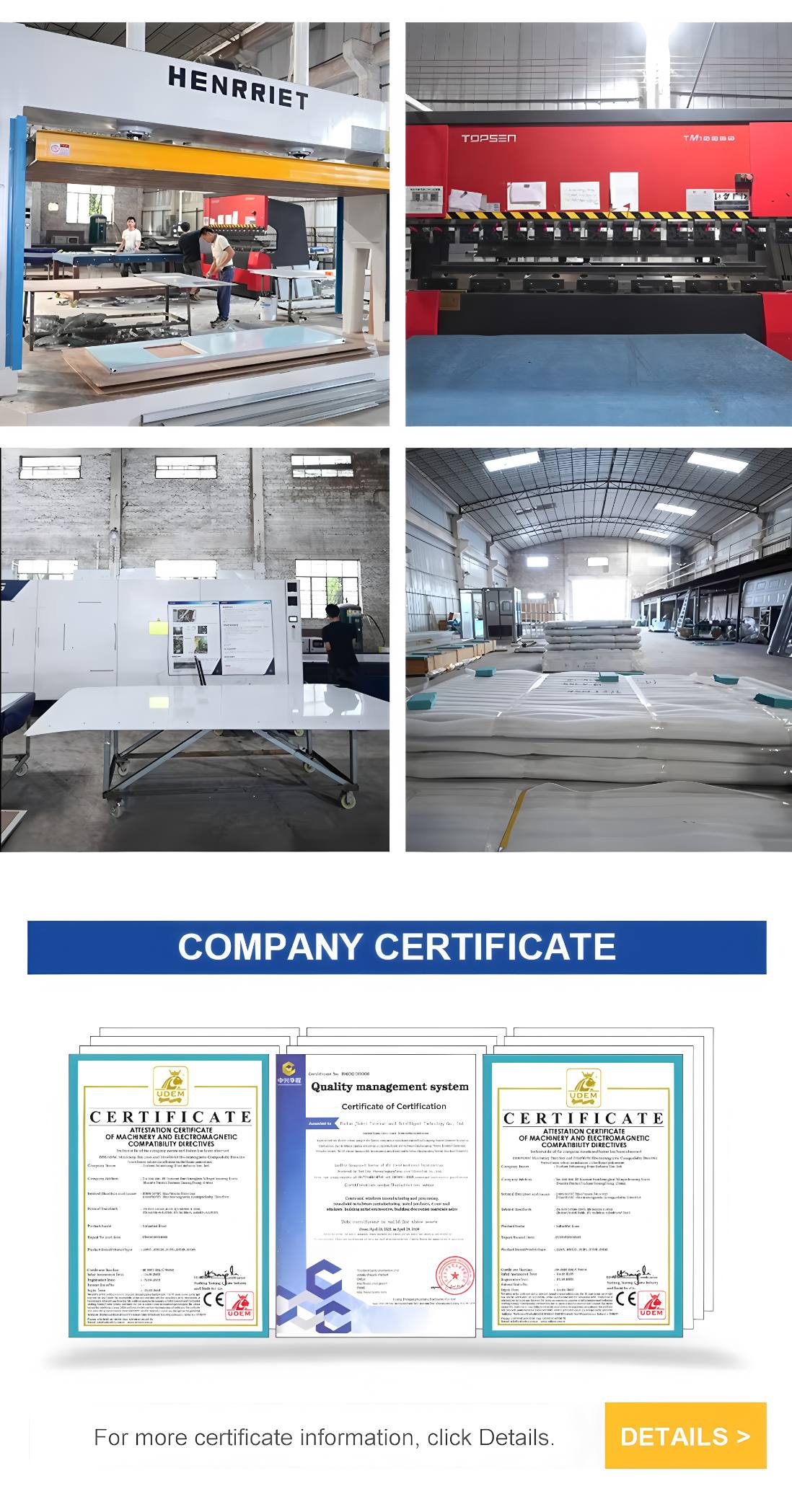

Production Process

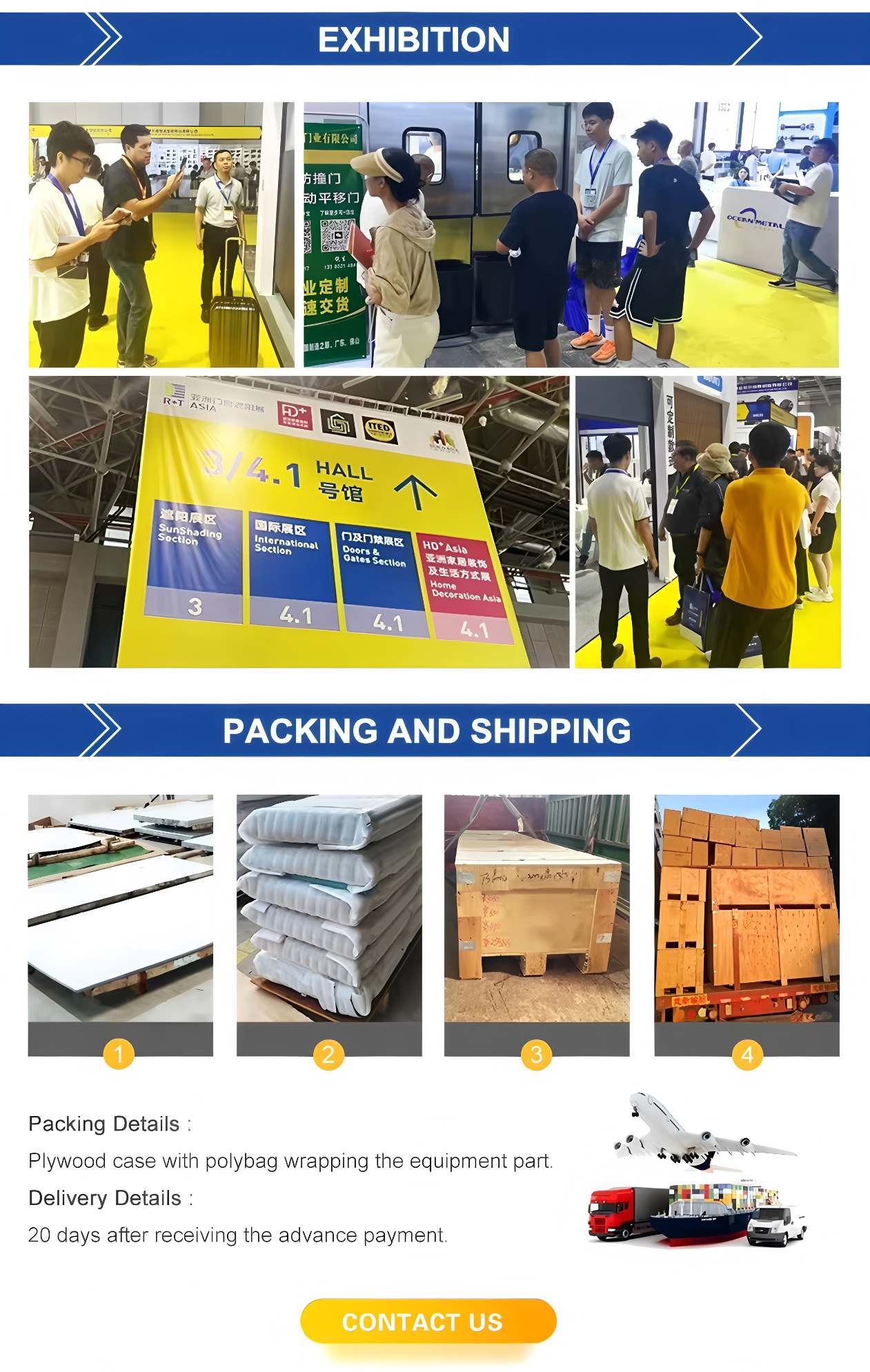

Exhibition & Package & Shipping

Product Applications

1. Production Workshop Passages

Suitable for high-frequency passage scenarios involving forklifts and AGV trolleys; automatically resets after impact without interrupting production line operations.

2. Warehousing and Logistics Loading/Unloading Areas

Quickly isolates the warehouse from the outdoor environment, reducing ingress of dust and rainwater while improving cargo turnover efficiency.

3. Cold Chain / Temperature-Controlled Storage

Excellent sealing and insulation performance minimizes cold loss, maintaining stable temperatures in cold storage facilities and temperature-controlled workshops.

4. Clean Workshops

Such as electronics factories, food processing plants, and pharmaceutical workshops; effectively blocks dust and odors, ensuring a high level of cleanliness in the production environment.

5. Automotive Manufacturing Workshops

Meets material transfer needs in welding, painting, and final assembly sections; impact-resistant and easy to maintain, suitable for complex production conditions.

7.E-commerce Sorting Centers

Matches the high-frequency rhythm of package sorting and transfer, reducing sorting delays caused by door malfunctions.

After-sales Service

1. Free Installation, Commissioning, and Training

Professional technical team provides on-site free installation and commissioning of the door body and control system, ensuring operating parameters meet usage standards. Additionally, one-on-one operational training is offered to logistics and equipment management teams, covering daily opening/closing, linkage settings, and basic troubleshooting, along with provision of operation manuals and maintenance guidelines.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, and the complete unit with a 1-year warranty. During the warranty period, non-human-induced faults are repaired or parts replaced free of charge.

3. Regular Inspections and Preventive Maintenance

Within the warranty period, a technician conducts on-site inspections every 6 months to check door sealing performance, sensor sensitivity, motor operation status, etc., promptly replacing aging wearable parts (such as brush seals) and eliminating potential issues. After the warranty expires, an annual maintenance agreement can be signed for discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

Ensures timely supply of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

Provides lifetime free technical consultation to address various issues encountered during use. For future upgrades to door linkage functions (e.g., integration with new access control or fire safety systems), cost-price technical upgrade services are available, adapting to intelligent transformation needs in hospitals and similar facilities.

FAQS

1. Does the self-healing function really require no manual repair? How much impact can it withstand?

After the door curtain derails, it automatically resets during the next operating cycle without manual intervention. It is suitable for low-speed impacts from forklifts (generally ≤5 km/h). However, in cases of severe damage such as curtain tearing or guide rail deformation, inspection and component replacement are still required.

2. What if the self-healing function fails? Common causes and solutions?

Common causes include debris blockage in the guide rails, imbalance in curtain tension, bearing wear, or curtain damage. First, clean debris from the guide rails, adjust roller tension, and lubricate bearings. If the issue persists, check for holes or tears in the curtain and replace it promptly.

3. What to do if the door stutters or makes loud noise during operation?

Stuttering is often caused by debris in the tracks, worn pulleys, or uneven clearance between the door body and guide rails. Loud noise typically results from insufficient lubrication, loose screws, or damaged motor bearings. Clean the tracks, replace pulleys, adjust clearance, apply lubricant, and tighten screws.

4. How to fix poor sealing, air leakage, or cold loss?

Main causes are aging/damaged sealing strips, door body deformation, or the bottom seal not fully contacting the ground. Replace the EPDM rubber strips, adjust door vertical alignment, and calibrate the bottom elastic sealing device.

5. How to select the right model for my application?

Choose based on door opening size (common: width ≤6m, height ≤5m), passage frequency (select 1-million-cycle model for high frequency), environment (thicker curtain + double sealing for cold chain), power supply (three-phase 380V), and safety features (photoelectric sensors + safety edges).

6. What daily maintenance is required and how often?

Daily: Clean sensors and check for curtain damage.

Weekly: Clear debris from guide rails and tighten screws.

Monthly: Lubricate bearings and calibrate safety devices.

Quarterly: Check curtain tension and sealing, replace aging rubber strips.

7. What safety protections are included? Can it prevent pinching?

Standard features include photoelectric sensors, wireless safety edges, and soft bottom edges; the door automatically stops or reverses upon detecting obstacles. With no hard metal components in the curtain, risk of injury to personnel and vehicles upon impact is low—ideal for high-frequency industrial scenarios.

8. How long is the service life? Are replacement parts expensive?

Standard service life exceeds 1 million cycles. Wearable parts such as curtains and sealing strips use universal modular design, are affordably priced, and can be replaced quickly without professional tools.

Procurement advantages

1. Core Advantage in Cost Reduction and Efficiency Improvement

Automatic reset after impact without manual repair, significantly reducing downtime and maintenance costs. Ideal for high-frequency forklift passage scenarios, ensuring uninterrupted production and logistics.

2. Outstanding Energy-Saving Performance

Full-perimeter sealing structure + high-speed opening/closing (0.8-2 m/s) effectively blocks cold/hot air exchange, dust, and odors, reducing air conditioning/heating energy consumption with significant long-term energy-saving benefits.

3. Comprehensive and Reliable Safety Protection

Standard photoelectric sensors, soft safety edges, and anti-collision reset design eliminate risks from hard metal impacts, providing all-round protection for personnel, vehicles, and equipment while complying with industrial safety standards.

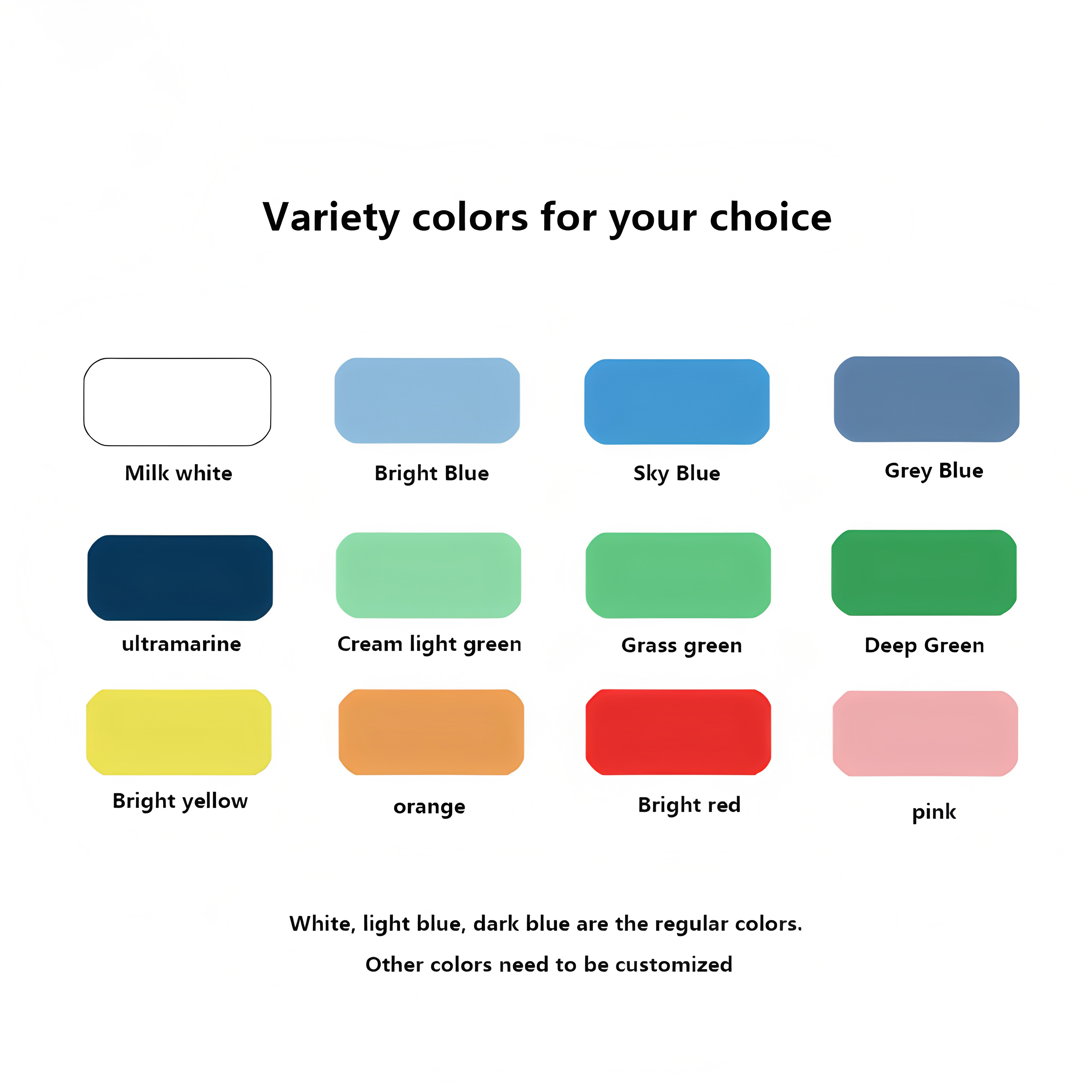

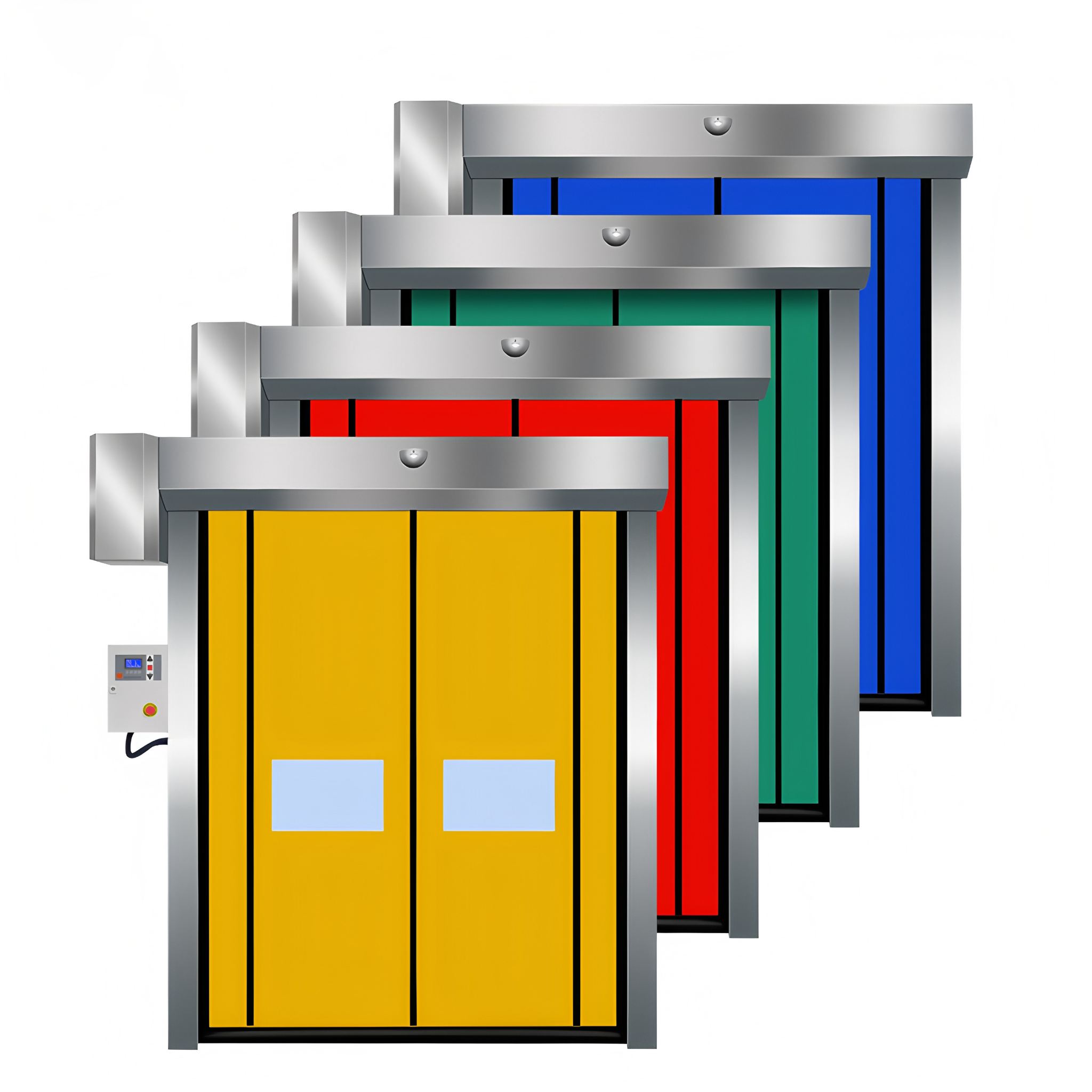

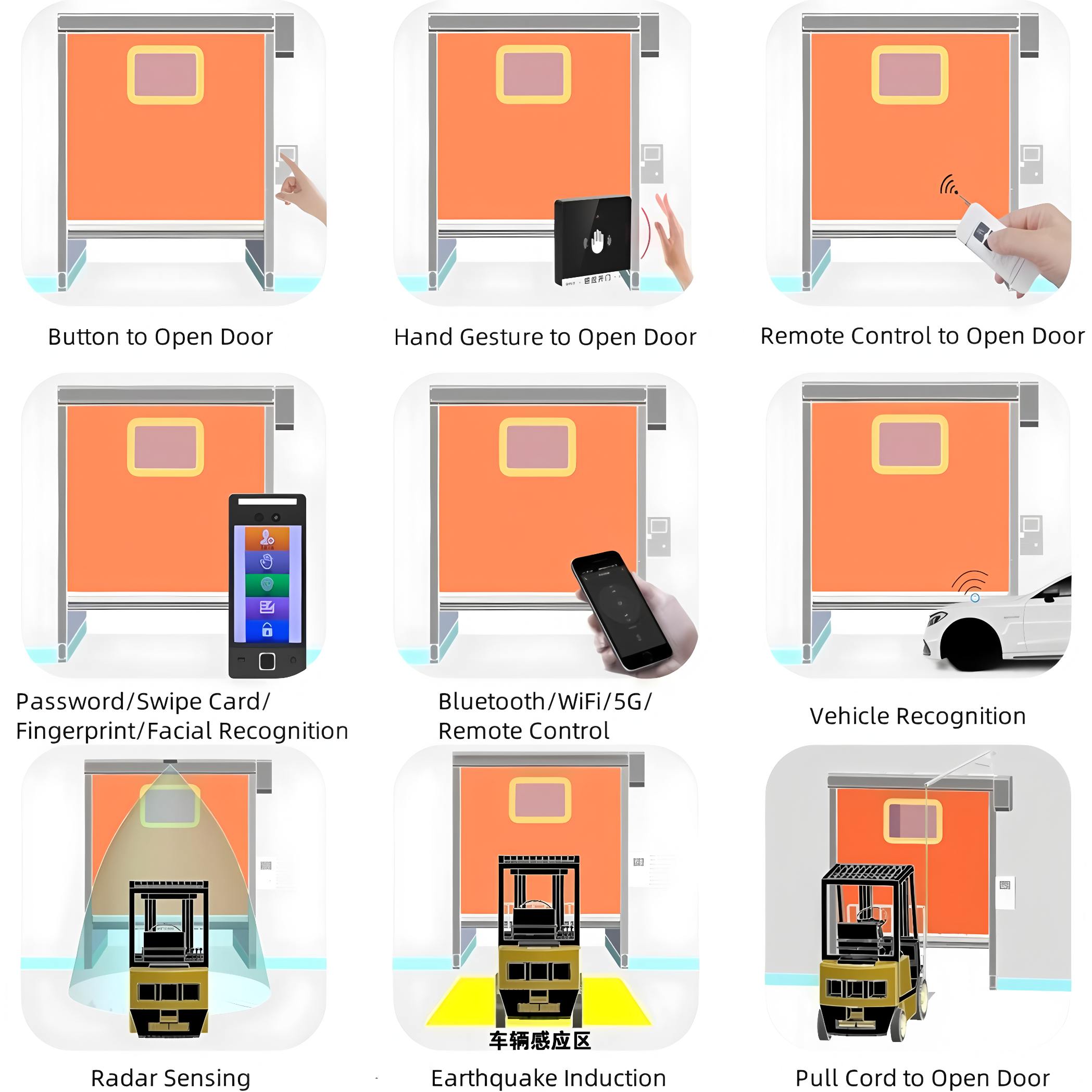

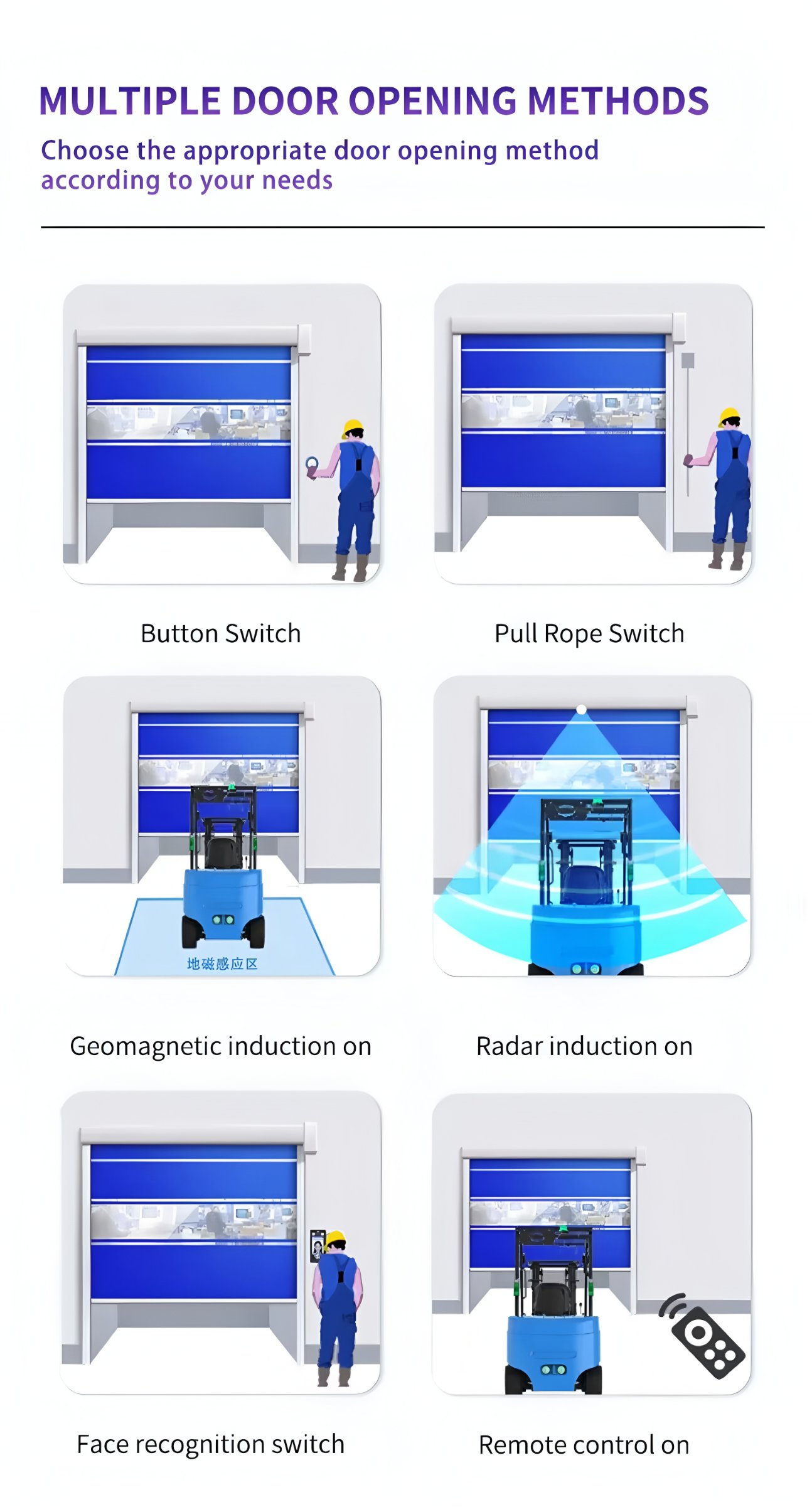

4. Highly Flexible Customization and Adaptability

Supports non-standard sizes (width ≤6m, height ≤5m), special materials (low-temperature/anti-static curtains), and functional customization (license plate recognition linkage, LOGO printing), suitable for diverse scenarios including warehousing, cold chain, and clean workshops.

5. High Cost Controllability in Procurement

Modular design with affordable, easily replaceable wearable parts (curtains, sealing strips); 1-year full unit warranty and core components exceeding 1 million cycles service life, lowering total long-term ownership costs.