Product Feature

1. Strong Load-Bearing and Sturdy Structure

Constructed with an aluminum alloy or steel frame and thickened door panels, the door offers high structural rigidity capable of withstanding external loads such as strong winds and snow accumulation. Suitable for large-span openings in factories and warehouses, it maintains shape stability over long-term use.

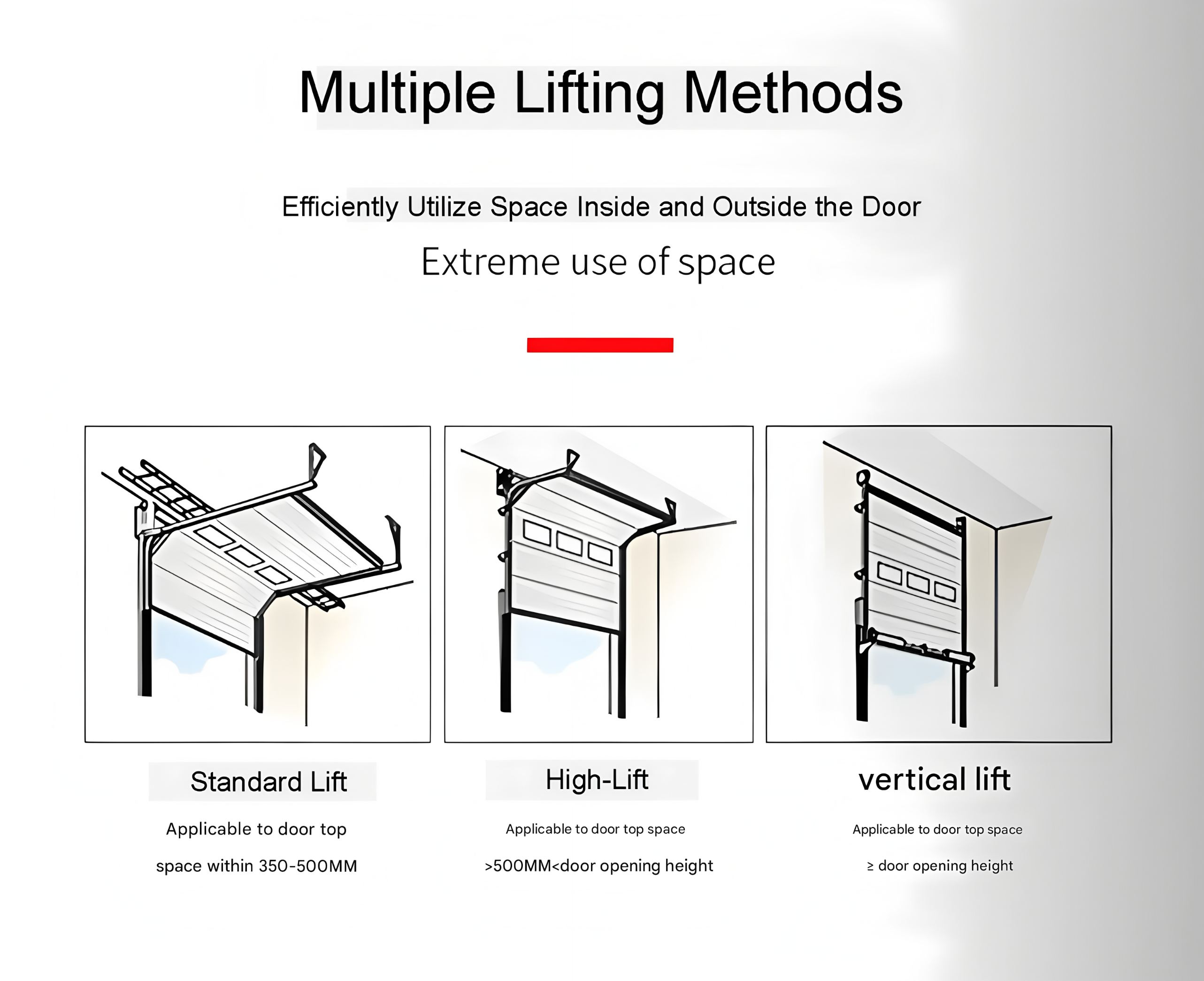

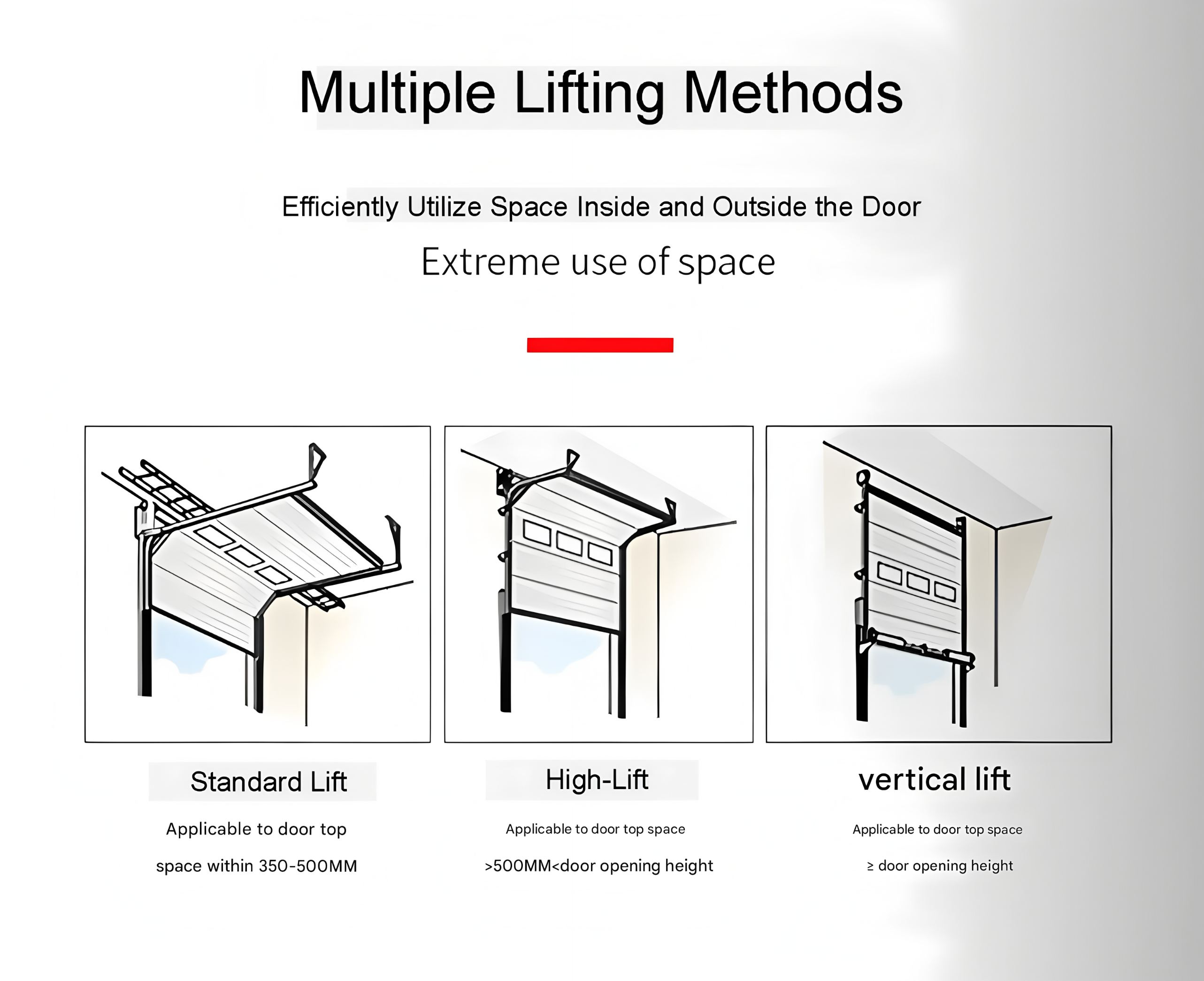

2. High Space Utilization

The door operates through vertical or side-sliding lifting along tracks, retracting above the opening when open. This design occupies no interior or exterior floor space, ensuring unobstructed passage for forklifts, trucks, and large equipment without interfering with goods storage.

3. Excellent Sealing and Insulation Performance

Equipped with EPDM rubber seals around the frame and polyurethane foam-filled panels, it effectively blocks dust, rainwater, and noise while minimizing indoor-outdoor thermal exchange. Ideal for cold storage, climate-controlled workshops, and other energy-sensitive environments.

4. Intelligent Safety and User-Friendly Operation

Supports multiple control methods including remote, push-button, and ground-loop sensors, and can integrate with access control systems. Standard safety features like anti-drop mechanisms and infrared safety edges automatically stop or reverse the door upon obstacle detection, ensuring personnel and equipment safety.

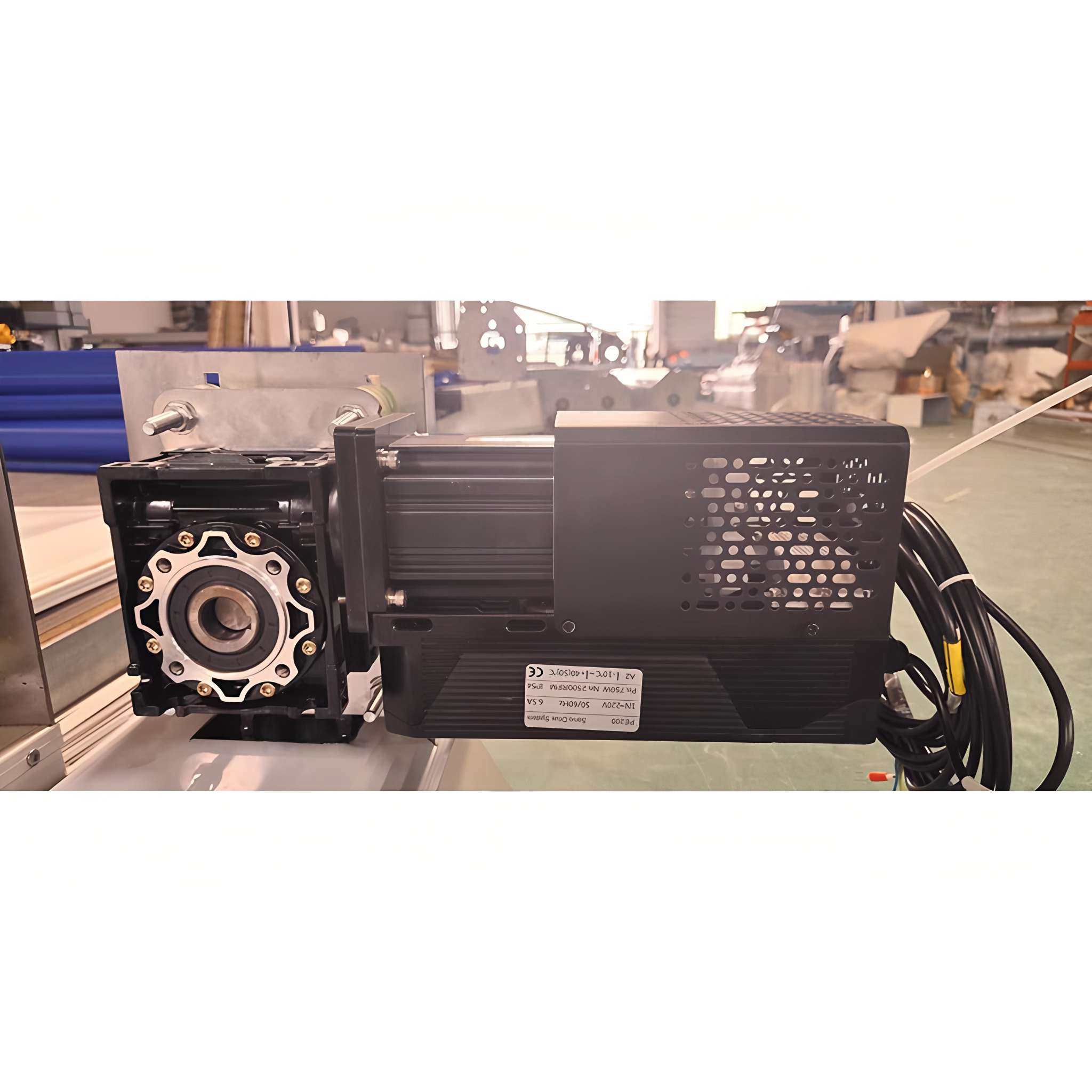

5. High Durability and Low Maintenance

Door surfaces undergo anti-corrosion treatments such as powder coating or galvanization for rust and wear resistance. High-quality motors in the drive system ensure low failure rates. Routine maintenance only involves periodic checks of tracks, seals, and motors.

6. High Customization Flexibility

Customizable based on opening dimensions and application needs, including panel materials (color steel, stainless steel, aluminum), colors, vision windows, and opening methods, catering to diverse requirements in industrial, logistics, and commercial sectors.

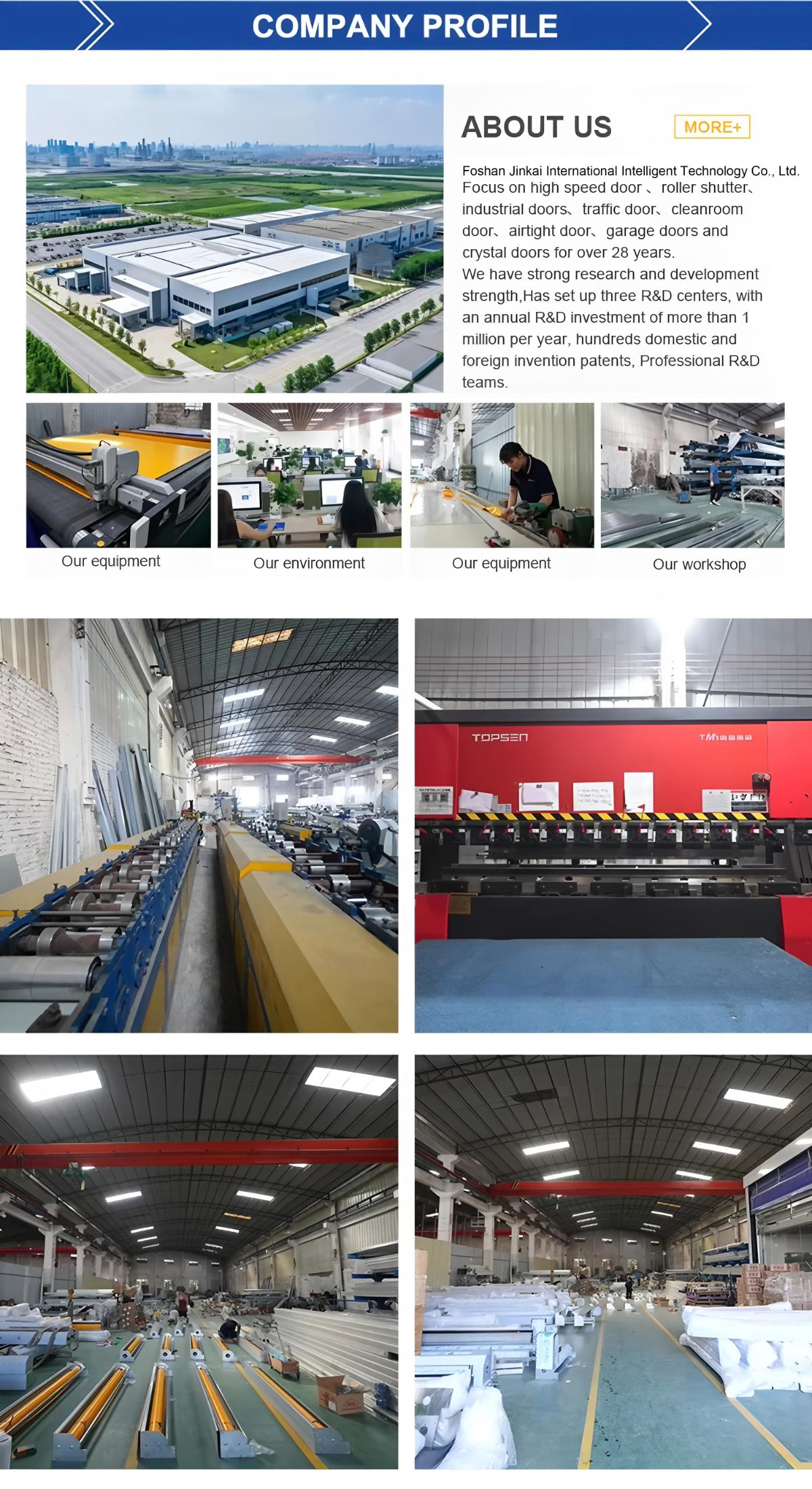

Product Description

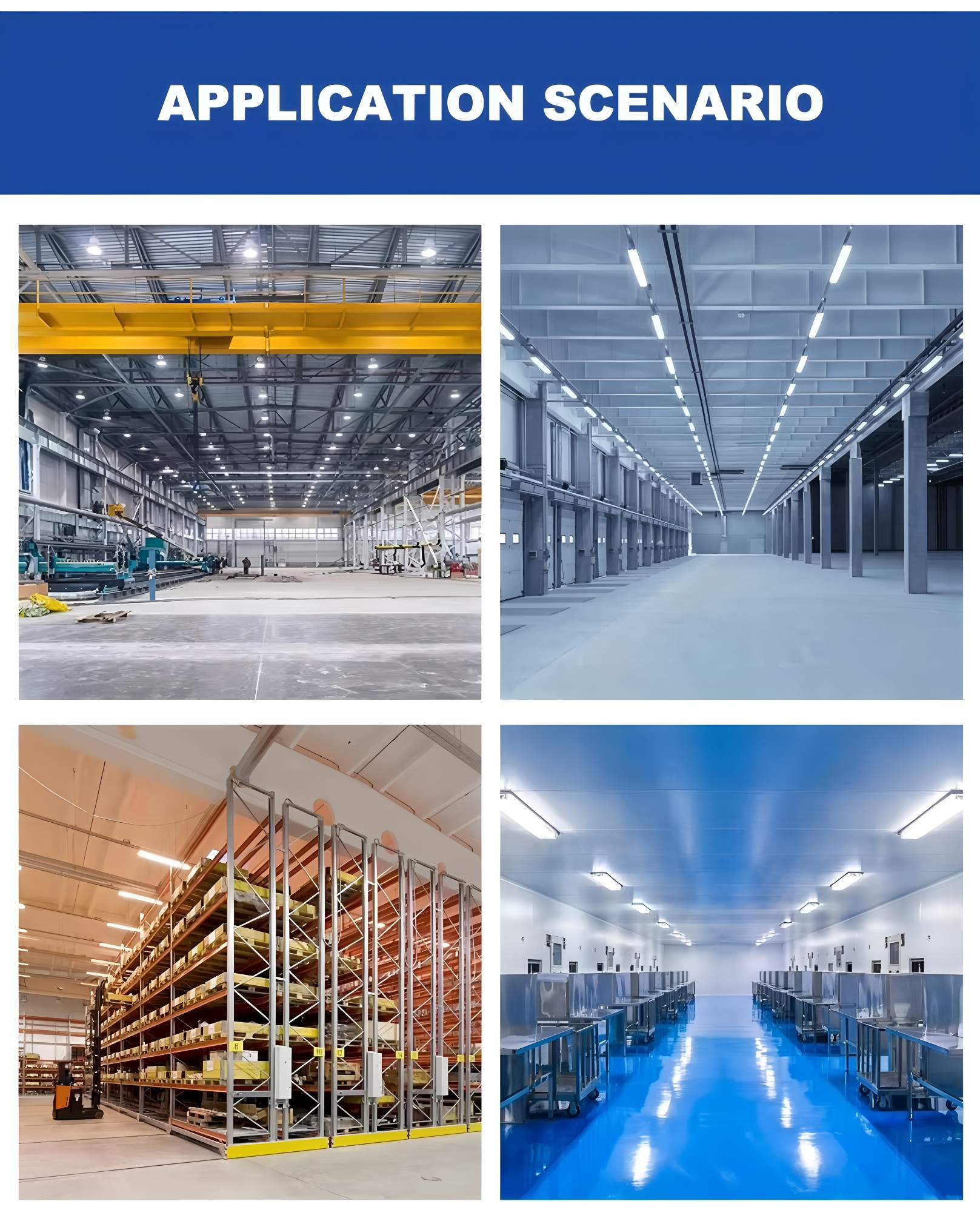

High-Speed Doors: Efficient Protection for Industrial and Logistics Applications

Designed specifically for large-span openings in industrial plants and warehouse facilities, high-speed doors offer robust performance and reliable protection.

Constructed with an aluminum alloy or steel frame and insulated panels filled with polyurethane foam, the door ensures structural strength and thermal efficiency. Complemented by EPDM rubber seals, it effectively withstands external loads, blocks dust and rainwater, and reduces energy consumption.

Operating via vertical lifting along tracks, the door retracts completely above the opening when open, freeing up space on both sides for unobstructed passage of forklifts and trucks. It supports multiple control methods, including remote and ground-loop sensors, and comes standard with safety features such as anti-drop mechanisms and infrared collision protection for enhanced operational safety.

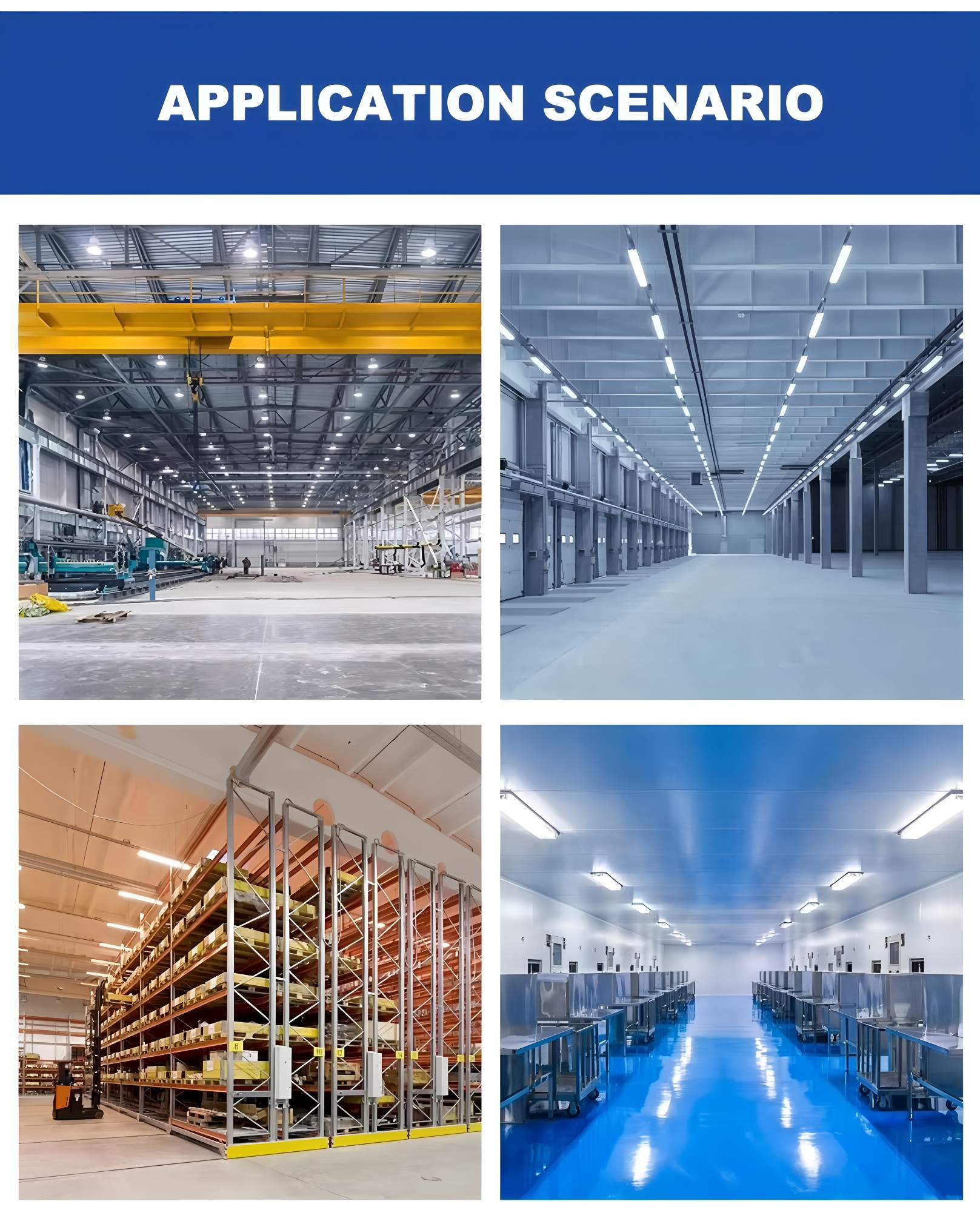

Customizable in panel material, dimensions, and vision windows, it meets diverse requirements across industrial, cold-chain, commercial, and other application scenarios.

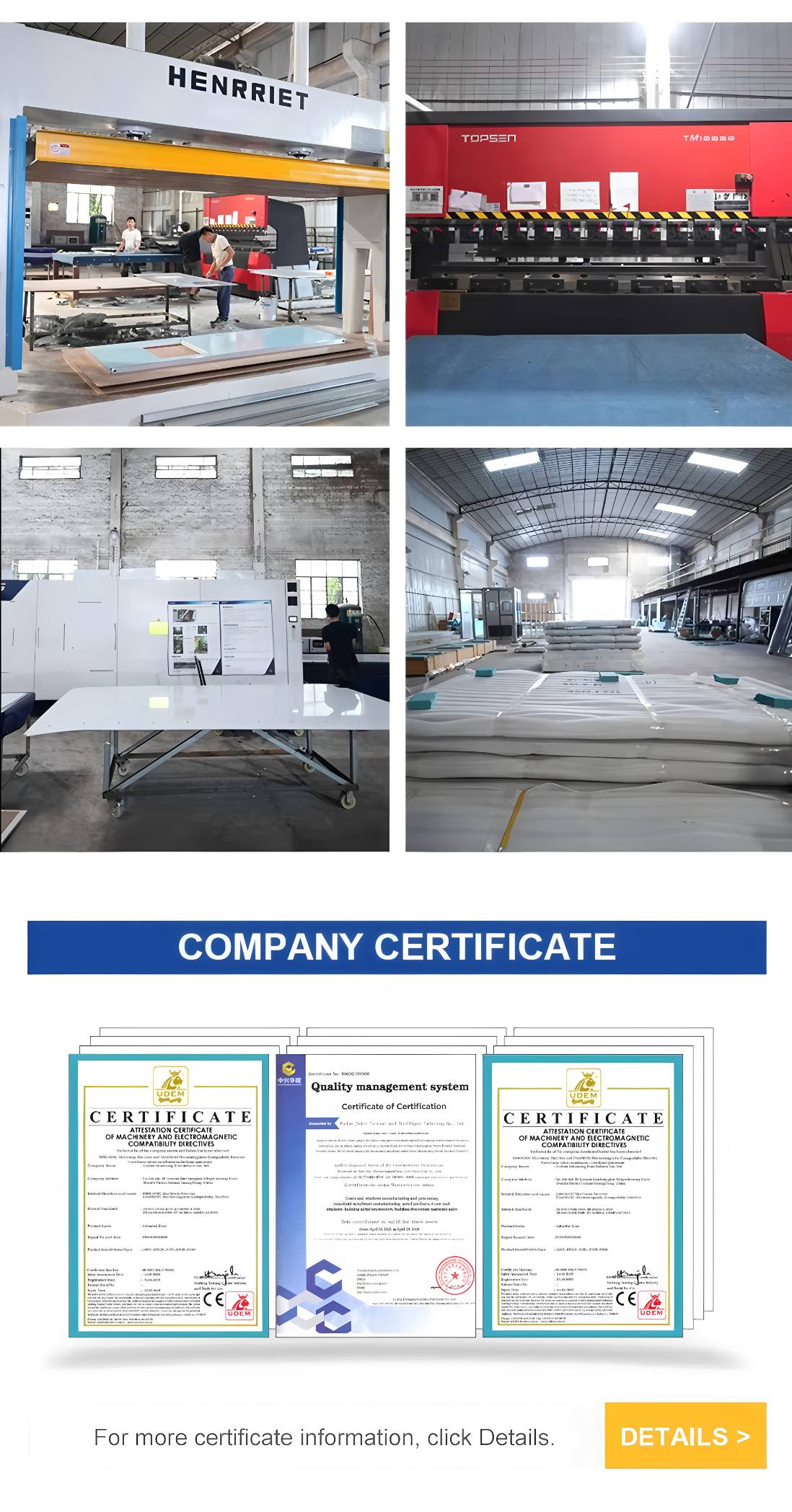

Production Process

Exhibition & Package & Shipping

Product Applications

1.Free Installation, Commissioning & Training

Our professional technical team provides complimentary on-site installation and commissioning of the door system and controls to ensure all operational parameters meet usage standards. We also offer one-on-one training for logistics and equipment management staff, covering daily operation, linkage configuration, basic troubleshooting, and more. Operation manuals and maintenance guidelines are provided.

2.Extended Warranty & Rapid Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the complete unit is guaranteed for 1 year. During the warranty period, repairs and part replacements for non-human-induced failures are provided free of charge.

3.Regular Inspection & Preventive Maintenance

During the warranty period, our technicians will conduct on-site inspections every 6 months to assess door sealing performance, sensor sensitivity, motor operation status, and other aspects. Aging or vulnerable parts (such as brush seals) will be replaced promptly to prevent potential failures. After the warranty expires, customers may sign an annual maintenance agreement to receive discounted inspections and priority repair services, extending the door’s service life.

4.Sufficient Spare Parts Inventory

We maintain an adequate stock of spare parts to ensure timely availability for repairs.

5.Lifetime Technical Support & Upgrade Services

We offer lifetime free technical consultation to address any operational inquiries. If upgrades to door linkage functions are required in the future—such as integration with new access control or fire safety systems—cost-effective upgrade services are available to meet intelligent renovation needs in settings such as hospitals.

After-sales Service

1.Free Installation, Commissioning & Training

A professional technical team will provide complimentary on-site installation and commissioning of the door and its control system to ensure all operational parameters meet usage standards. One-on-one training will also be conducted for facility and equipment management teams, covering daily start/stop, linkage setup, basic troubleshooting, and other relevant content. Operation manuals and maintenance guides will be provided.

2.Extended Warranty & Quick Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire unit is covered by a 1-year warranty. During the warranty period, repairs and parts replacement for non-human-induced failures are provided free of charge.

3.Regular Inspection & Preventive Maintenance

During the warranty period, technicians will perform on-site inspections every 6 months to evaluate door sealing performance, sensor sensitivity, motor operation, and other key aspects. Aging or vulnerable parts (such as brush seals) will be replaced in a timely manner to prevent potential malfunctions. After the warranty expires, customers can sign an annual maintenance agreement to enjoy discounted inspections and priority repair services, thereby extending the door's service life.

4.Sufficient Spare Parts Inventory

We maintain an adequate inventory of spare parts to ensure timely supply for repairs and replacements.

5.Lifetime Technical Support & Upgrade Service

Lifetime free technical consultation is provided to answer any questions that may arise during use. Should upgrades to the door linkage function be needed in the future—such as integration with new access control or fire protection systems—cost-based technical upgrade services are available to meet the needs of smart facility upgrades, such as those in hospitals.

FAQS

1.Q: Is the lift door suitable for large-span openings? How is its wind resistance?

A: Yes, highly suitable. The lift door is constructed with an aluminum alloy or steel frame and thickened foam-filled panels, offering strong structural rigidity. It can be customized for large-span dimensions to fit factory and warehouse openings. Additionally, reinforced wind-resistant ribs are integrated to withstand strong wind loads and prevent deformation.

2. Q: Does the lift door occupy side space when opened?

A: No, it does not. The lift door operates through vertical or horizontal lifting along tracks and retracts completely above the opening when open. This design frees up both interior and exterior floor space, ensuring unobstructed passage for forklifts and trucks without affecting goods storage.

3. Q: How effective is the sealing and insulation of the lift door? Can it be used in cold storage warehouses?

A: Sealing and insulation performance are excellent. EPDM rubber seals surround the door frame, and panels are filled with high-density polyurethane foam, effectively blocking heat/cold transfer, dust, and noise. It is fully suitable for cold storage warehouses, reducing cold air leakage and lowering energy consumption.

4. Q: Is there a risk of the lift door falling during operation?

A: No. The door comes standard with anti-drop mechanisms, overload protection, and infrared safety edges. If an obstacle is detected during operation, the door automatically stops or reverses. In unexpected events such as cable breakage, the anti-drop system locks the door in place to ensure safety.

5. Q: Is daily maintenance for the lift door complicated? What should be noted?

A: Maintenance is straightforward. Regularly clear debris from the tracks and check the condition of seals, motor operation, and cable tension. The door surface can be wiped clean with a damp cloth, requiring no special upkeep, which keeps maintenance costs low.

Procurement advantages

1.Large-Span Adaptability Advantage

Featuring a steel/aluminum alloy frame and thickened insulated panels, the door can be customized to extra-wide and extra-high dimensions, fitting large-span openings in factories and warehouses. It provides strong wind load resistance and maintains structural stability without deformation.

2.Space Utilization Advantage

The door lifts vertically and retracts completely above the opening, occupying no floor space on either side of the doorway. This allows free passage for forklifts and trucks, maximizes storage space, and enhances site efficiency.

3.Sealing & Energy Efficiency Advantage

With full-perimeter EPDM rubber seals and polyurethane foam-filled panels, the door blocks dust, rainwater, and heat/cold exchange, effectively reducing energy consumption in temperature-controlled workshops and cold-chain storage facilities, thereby lowering long-term operating costs.

4.Safety & Reliability Advantage

Equipped with standard safety features including anti-drop mechanisms, infrared safety edges, and overload protection, it supports remote, ground-loop, and access control integration. The door stops immediately upon obstacle detection during operation, ensuring safety for personnel and equipment.

5.Durability & Low Maintenance Advantage

Panels are finished with powder-coated or galvanized anti-corrosion treatments for rust and wear resistance. The drive motor operates with low failure rates. Daily maintenance only requires cleaning tracks and inspecting seals, keeping upkeep costs minimal.

6.Customization Flexibility Advantage

Customizable with options for panel material, color, vision windows, and opening methods to meet personalized needs across diverse applications such as industrial production, logistics warehousing, and commercial venues.