Product Feature

1.Exceptional Insulation and Sealing Performance

The door body is filled with high-pressure polyurethane foam, achieving a thermal conductivity coefficient as low as 0.022W/(m·K). Combined with double-layer sealing strips and compression devices around the frame, it effectively blocks heat and cold transfer, prevents cold air leakage, and ensures a stable temperature environment in cold storage facilities.

2.Durable and Impact-Resistant

The door panels are made of 304 stainless steel or color-coated steel, offering corrosion resistance and wear durability. The reinforced steel-welded frame withstands minor collisions from forklifts and handling equipment, making it suitable for high-frequency loading and unloading scenarios in cold storage environments.

3.Intelligent Safety Protection Design

Standard features include anti-pinch mechanisms and emergency escape unlocking systems, allowing manual operation during power outages. Some high-end models are equipped with anti-condensation heating wires to prevent frost or ice buildup on the door frame due to temperature differences, ensuring smooth operation and safe passage for personnel.

4.Adaptable to Harsh Low-Temperature Environments

All hardware components (hinges, locks) are made of low-temperature-resistant and rust-proof materials, ensuring stable operation across a wide temperature range of -40°C to +8°C. This prevents issues such as component freezing, cracking, or jamming, making it suitable for various cold storage types, including freezers, refrigerated warehouses, and rapid freezing tunnels.

5.Flexible Installation and Easy Maintenance

Supports both single and double opening methods, with door dimensions customizable as needed. The modular structural design allows for easy replacement of sealing strips and hardware components without dismantling the entire door, resulting in low maintenance costs and uninterrupted cold storage operations.

Product Description

This hinge-type cold storage door is a specialized thermal insulation partition solution for freezers, refrigerated warehouses, and rapid freezing tunnels.

The door panels are made of 304 stainless steel or color-coated steel and filled with high-pressure polyurethane foam, achieving a thermal conductivity coefficient as low as 0.022W/(m·K). Combined with dual sealing strips and compression devices, it effectively locks in temperature and prevents cold leakage. All hardware components are crafted from low-temperature-resistant and rust-proof materials, ensuring stable operation in temperatures ranging from -40°C to +8°C without issues like freezing, cracking, or jamming.

The door comes standard with anti-pinch mechanisms and emergency escape features, while higher-end models are equipped with anti-condensation heating wires to ensure the safety of personnel and goods during transit. It supports customization for single or double opening, and its modular design simplifies future maintenance without disrupting normal cold storage operations.

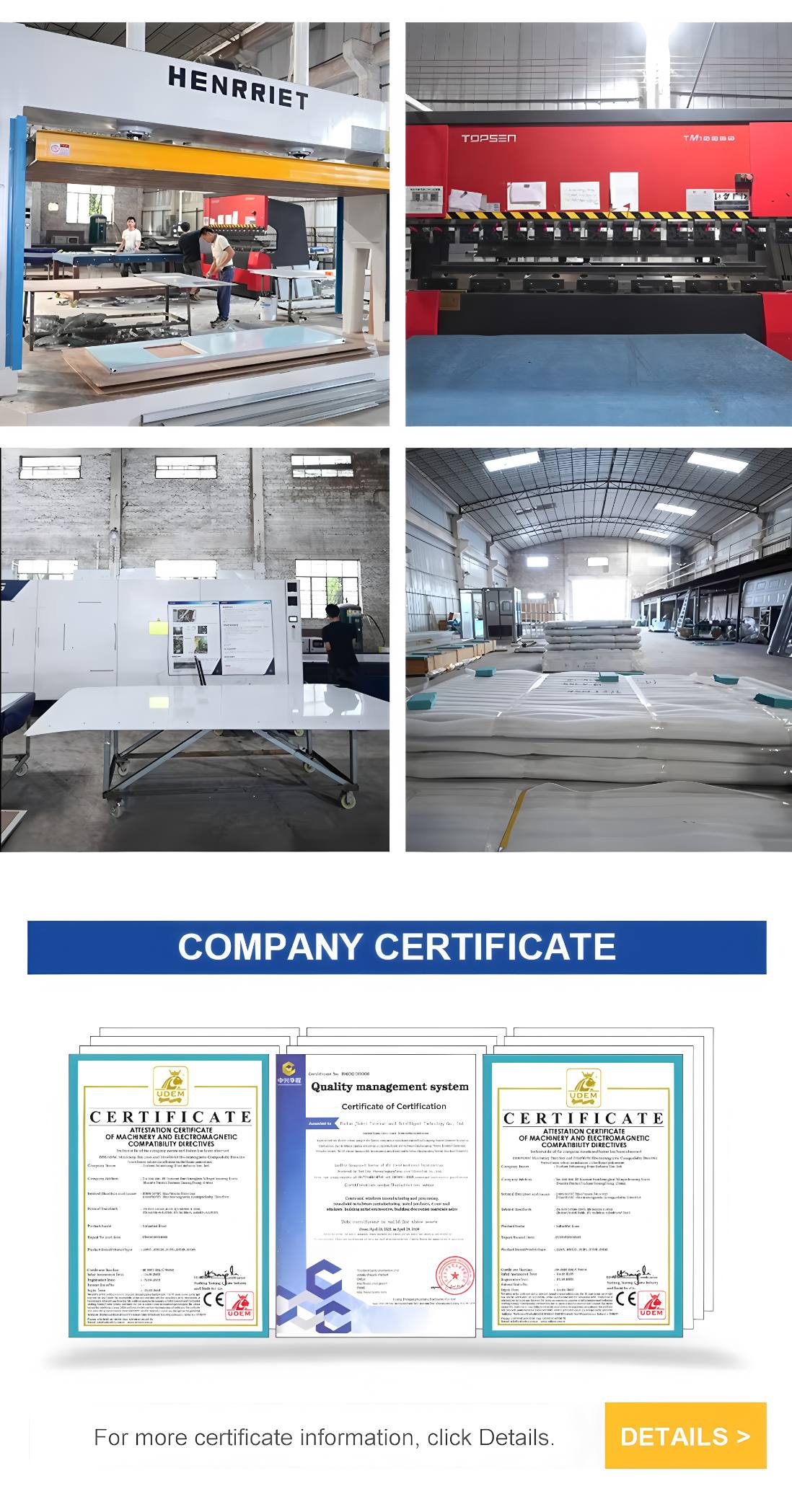

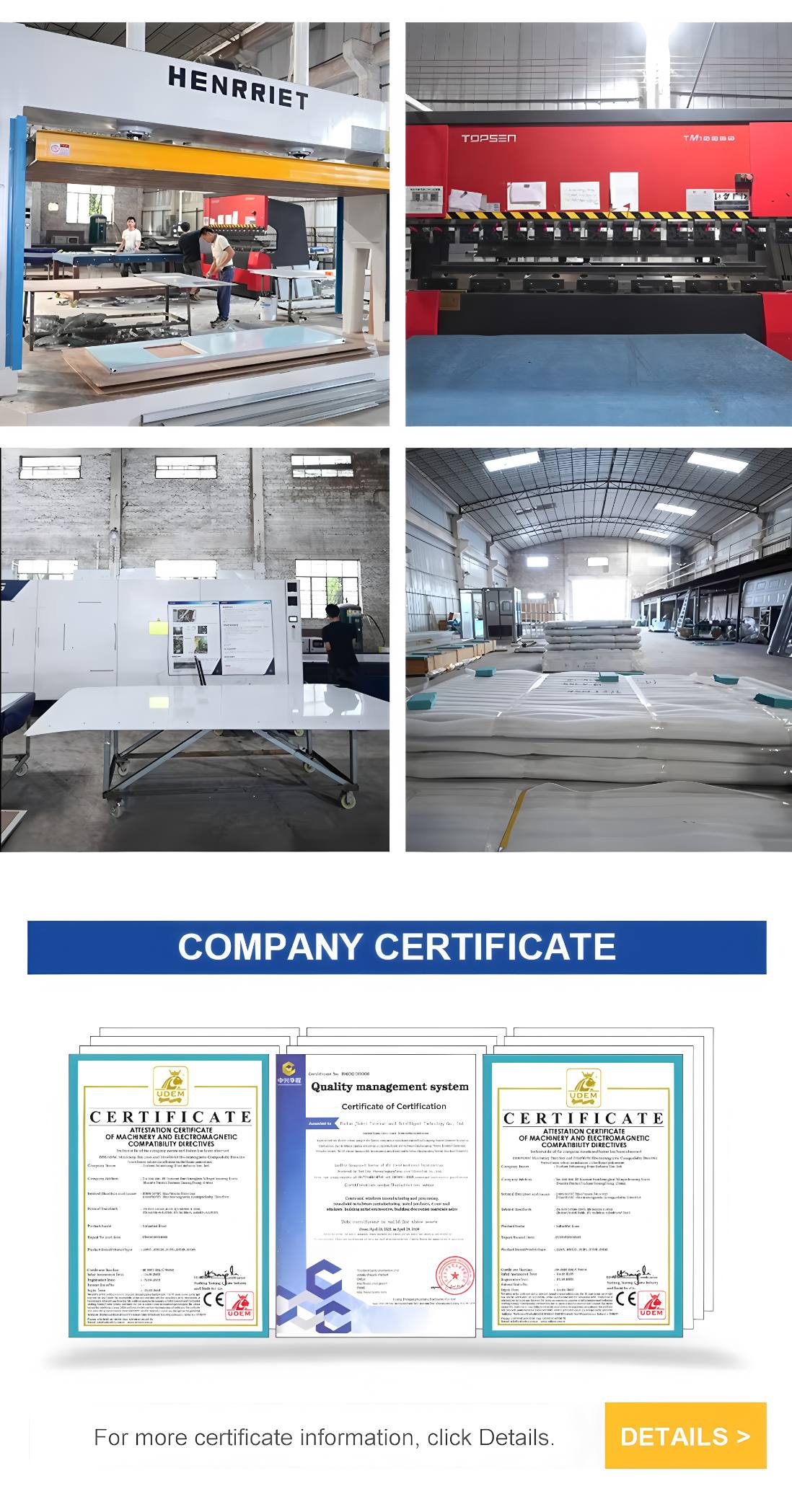

Production Process

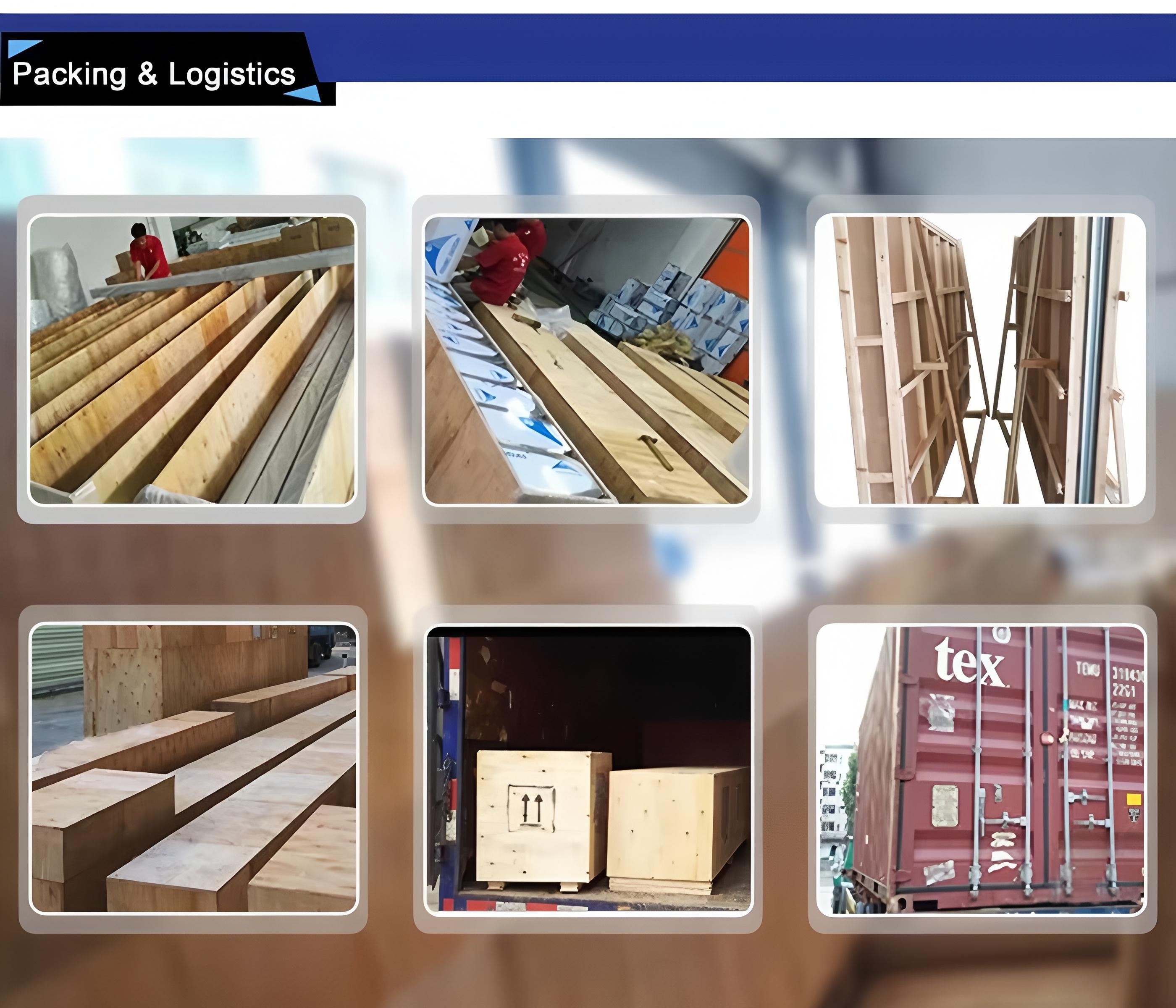

Package & Shipping

Product Applications

1.Food Freezing/Refrigeration Storage

Suitable for the entrances and exits of fresh meat storage, frozen food storage, and fruit/vegetable preservation rooms. Excellent thermal insulation and sealing performance help maintain a stable low temperature of -18°C to 0°C inside the storage, reducing energy consumption of the refrigeration system and ensuring food storage quality.

2.Pharmaceutical Cold Chain Warehouses

Used for partition walls in warehouses storing vaccines, biologics, and low-temperature pharmaceuticals. The low-temperature-resistant hardware ensures stable operation in extreme cold down to -40°C. The sealing structure effectively isolates external contamination, complying with GMP certification standards for pharmaceutical cold chains.

3.Rapid Freezing Tunnels/Processing Workshops

Connects rapid freezing production lines with processing areas. The door body is impact-resistant and wear-resistant, capable of withstanding frequent collisions from forklifts entering and exiting. It also blocks air exchange between the low-temperature tunnel and the ambient temperature of the workshop, reducing production energy consumption.

4.Low-Temperature Storage for Chemical Raw Materials

Designed for chemical raw materials and reagents requiring low-temperature and light-protected storage. The stainless steel door panel is corrosion-resistant and rust-proof. The sealing design prevents the volatilization and leakage of materials, meeting the special storage needs of the chemical industry.

5.Cold Chain Logistics Transit Warehouses

Used for partition walls in cold chain logistics sorting centers. The flexible single/double door opening design adapts to different passage widths, while the emergency escape mechanism ensures quick evacuation of personnel in case of emergencies such as power outages.

After-sales Service

1. Free Installation, Commissioning, and Training

A professional technical team will provide complimentary on-site installation and commissioning of the door body and control system to ensure operational parameters meet usage standards. One-on-one operational training is provided for logistics and equipment management teams, covering daily start-stop procedures, linkage settings, basic troubleshooting, and more. Operation manuals and maintenance guides are distributed for reference.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire machine carries a 1-year warranty. During the warranty period, faults not caused by human damage will be repaired free of charge, including the replacement of necessary parts.

3. Regular Inspections and Preventive Maintenance

During the warranty period, technicians will conduct on-site inspections every 6 months to evaluate the door's sealing performance, sensor sensitivity, motor operation status, and more. Aging or vulnerable components (e.g., brush seals) will be promptly replaced to prevent potential failures. After the warranty expires, customers may sign an annual maintenance agreement to enjoy discounted inspection and prioritized repair services, extending the door's lifespan.

4. Adequate Spare Parts Inventory

Ensures timely supply of maintenance and replacement parts.

5. Lifetime Technical Support and Upgrade Services

Lifetime complimentary technical consultation is available to address any operational issues. If future upgrades to the door's linkage functionality are needed—such as integration with new access control or fire safety systems—cost-price technical upgrade services can be provided to support hospital intelligent renovation requirements.

FAQS

Q: What should I do if the cold storage door leaks cold air and the door frame develops severe frost after a period of use?

A: First, check whether the sealing strips on the door frame are aged, deformed, or detached, and replace damaged strips promptly. Adjust the door compression device to ensure a tight seal between the door body and frame. If used in low-temperature, high-humidity environments, consider installing anti-condensation heating wires on the door frame to prevent frost buildup and maintain sealing effectiveness.

Q: Why does the insulation performance of the door decline, leading to higher energy consumption in the cold storage?

A: This is likely due to voids or localized damage in the polyurethane filling layer of the door, which reduces its insulation efficiency. It could also result from gaps between the door panel and the filling layer, allowing air infiltration. It is recommended to inspect the integrity of the door, repair damaged areas with specialized sealing adhesive, and replace the door body in severe cases.

Q: How can I resolve issues where the cold storage door becomes stiff or fails to open in low-temperature environments?

A: First, check whether hardware components such as hinges and locks are frozen or rusted due to low temperatures, and apply specialized low-temperature-resistant lubricant. For electric doors, inspect whether the motor reducer is affected by low temperatures, and replace motor components with those suitable for cold environments. Additionally, clear any ice, frost, or debris between the door frame and the door body.

Q: Why does the manual cold storage door require excessive force to open or close?

A: This may be due to misalignment during installation, causing uneven force distribution during operation, or wear or obstruction in the hinge bearings. First, adjust the vertical alignment of the door, then clean the hinge bearings and apply lubricant. Replace severely worn bearing parts if necessary.

Q: What should I do if the cold storage door cannot be opened manually during a power outage?

A: Hinge-type cold storage doors are equipped with an emergency escape unlocking mechanism, usually located on the side or bottom of the door. Locate the emergency handle or lock hole and follow the instructions in the manual to unlock it manually. Regularly test the emergency mechanism to prevent malfunction due to prolonged disuse.

Q: What should be noted in the daily maintenance of cold storage doors?

A:1.Clean the door frame sealing strips monthly to prevent oil, dirt, or frost from affecting the seal.

2.Apply low-temperature-resistant lubricant to hinges and locks to prevent rust and stiffness.

3.Regularly inspect the door panels and filling layers for damage, and repair promptly.

4.For electric doors, regularly check the motor and wiring to prevent short circuits caused by low temperatures or moisture.

Procurement advantages

1. Ultimate Thermal Insulation & Energy Efficiency, Lower Operating Costs

The door is filled with high-density polyurethane foam, featuring an exceptionally low thermal conductivity coefficient of 0.022W/(m·K). Combined with dual sealing strips and a compression structure, it achieves near-zero cold air leakage, significantly reducing refrigeration system energy consumption in cold storage facilities and delivering substantial long-term energy savings.

2. Low-Temperature Resistance & Impact Strength, Built for Harsh Working Conditions

Door panels are made of 304 stainless steel or thickened color-coated steel, while all hardware components are constructed from low-temperature-resistant and anti-rust materials, ensuring stable operation in temperatures ranging from -40°C to +8°C. The reinforced welded steel door frame can withstand frequent forklift collisions, extending the door’s service life by over 30% compared to conventional cold storage doors.

3. Comprehensive Safety Protection, Meeting Industry Standards

Standard features include anti-pinch mechanisms and an emergency escape unlocking device for quick manual operation during power outages. High-end models are additionally equipped with anti-condensation heating wires on the door frame to eliminate frost formation and potential jamming. These features fully comply with safety requirements for food cold chains and GMP-certified pharmaceutical storage.

4. Customizable, Easy to Install & Maintain

Supports single or double opening designs and can be customized to extra-large dimensions, tailored to various cold storage doorway specifications. The modular structure allows for on-site installation without extensive civil engineering work. For future maintenance, sealing strips and hardware components can be replaced without disassembling the entire door, ensuring low maintenance costs and high efficiency.