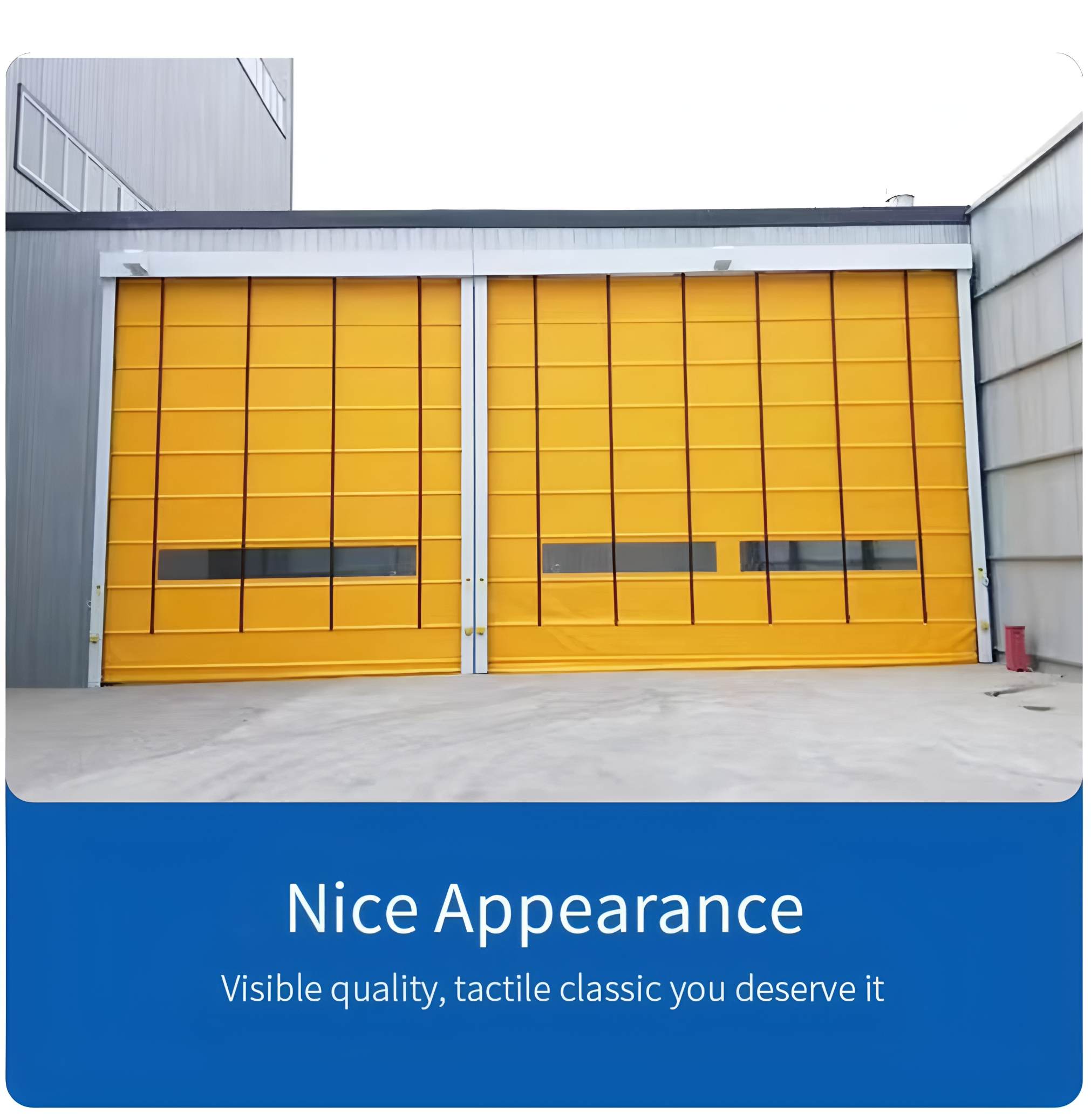

Product Feature

1.Ultra-High Opening/Closing Efficiency

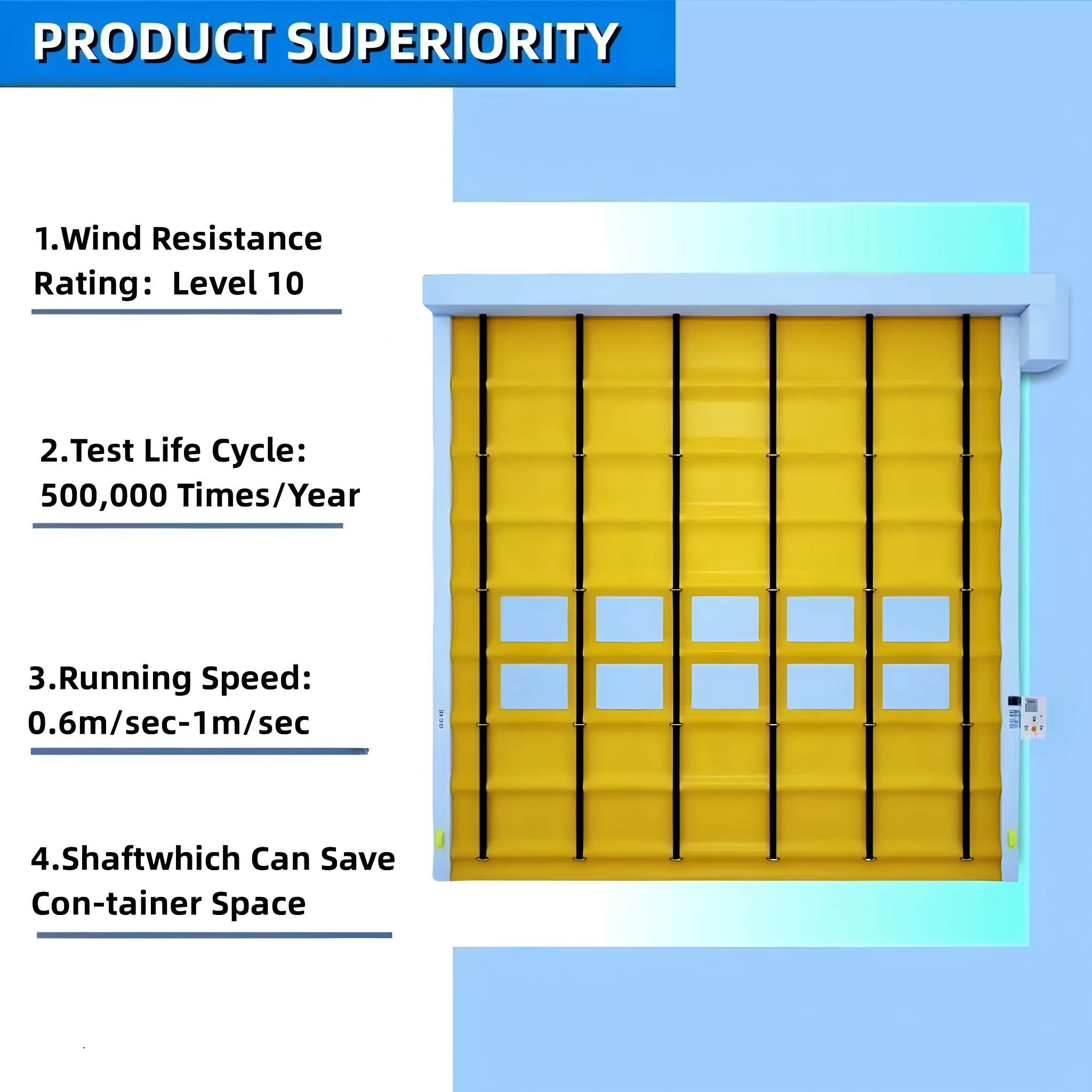

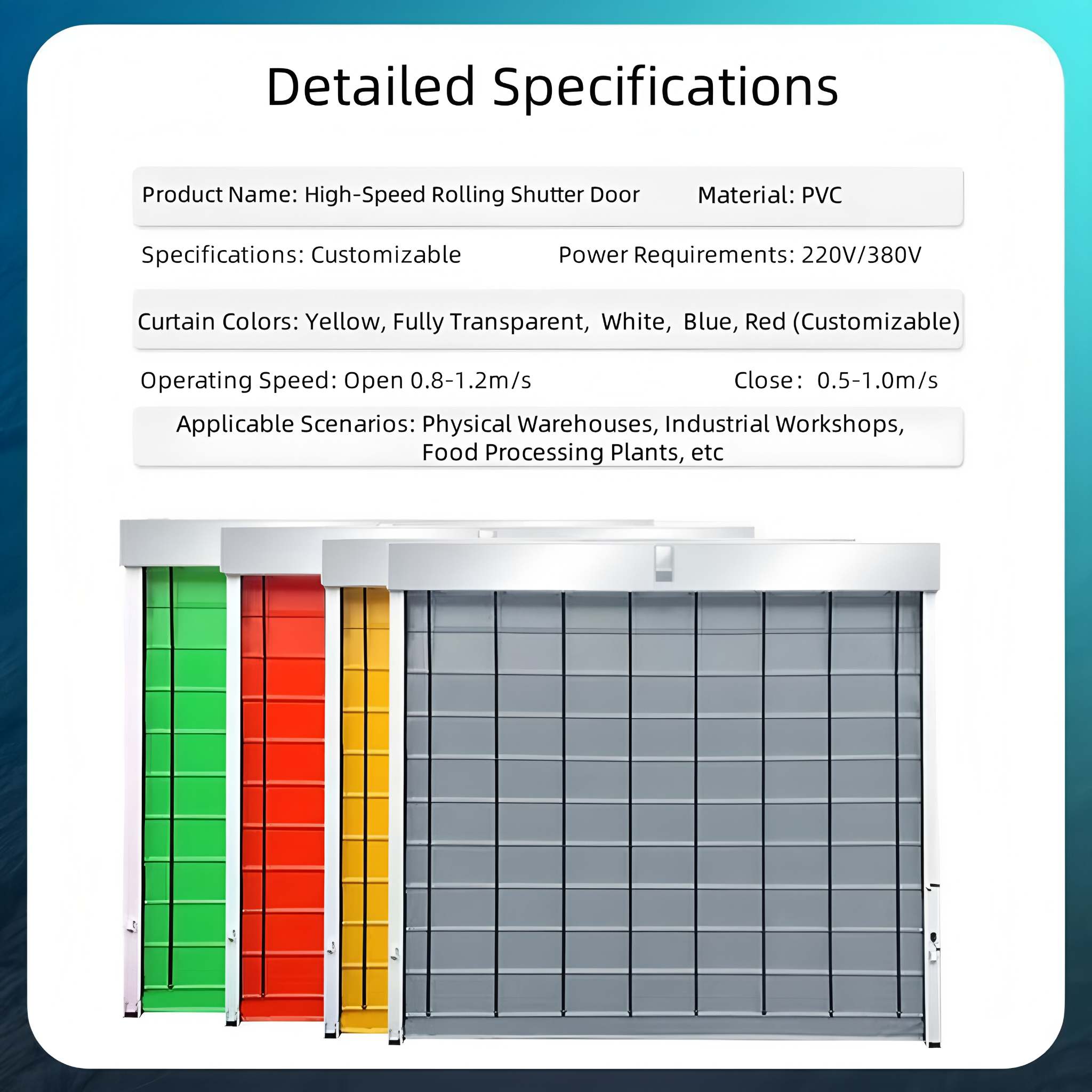

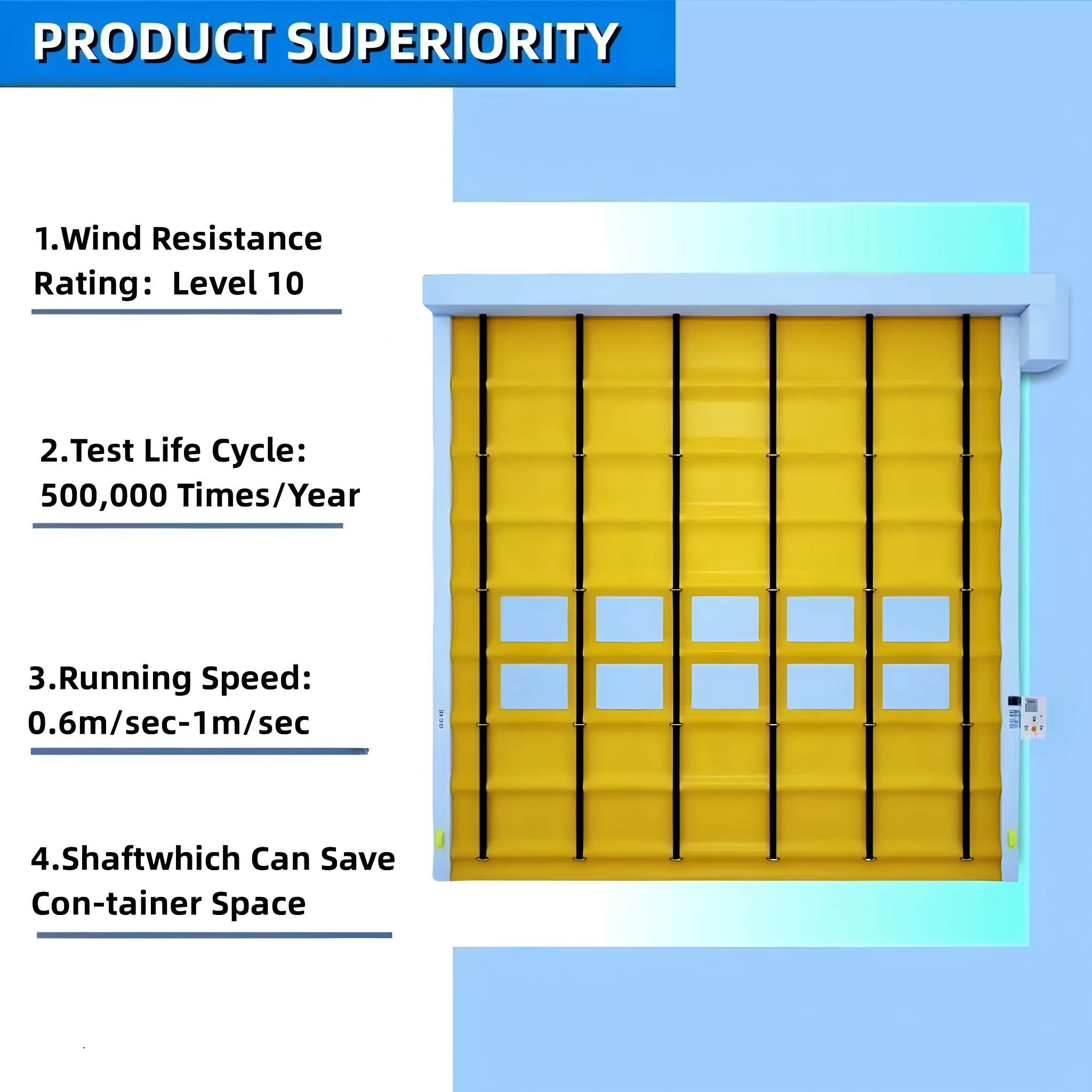

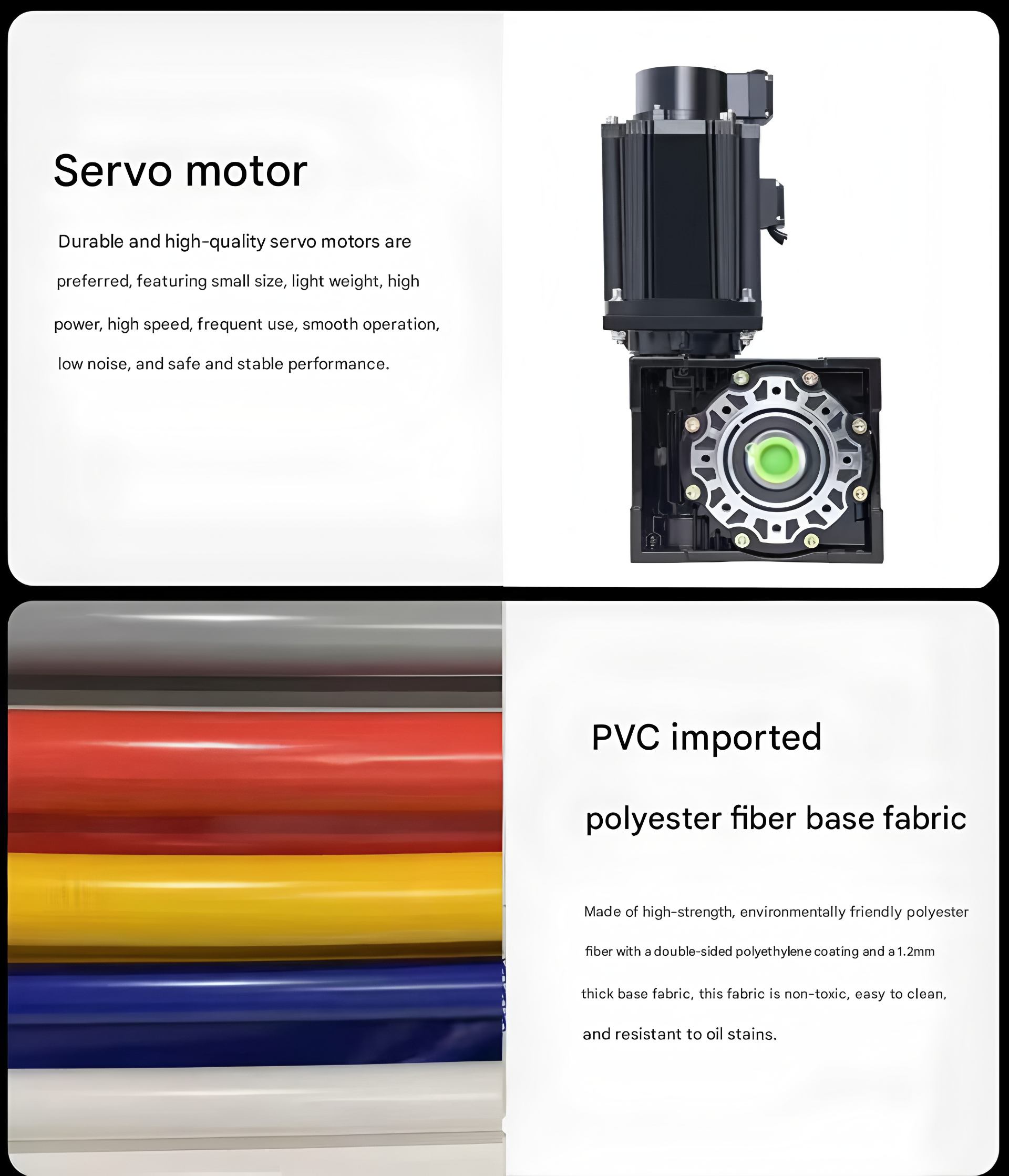

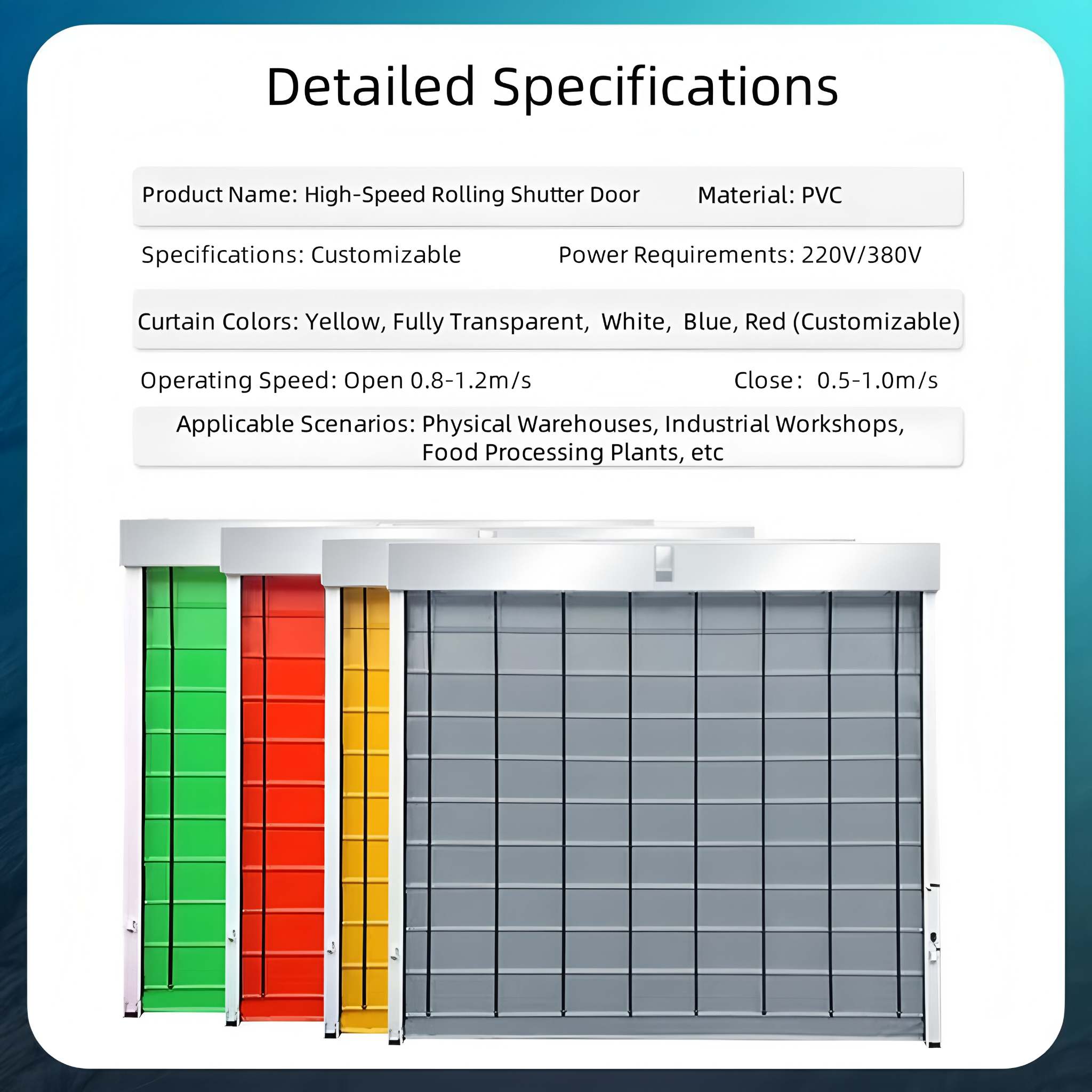

Driven by a servo motor and featuring a lightweight door body design, the door achieves an opening/closing speed of 0.8–1.5 m/s, far exceeding that of traditional rolling doors. It quickly separates indoor and outdoor workshop spaces, reduces air conditioning energy loss, enhances logistics vehicle passage efficiency, and is suitable for high-frequency entry and exit scenarios.

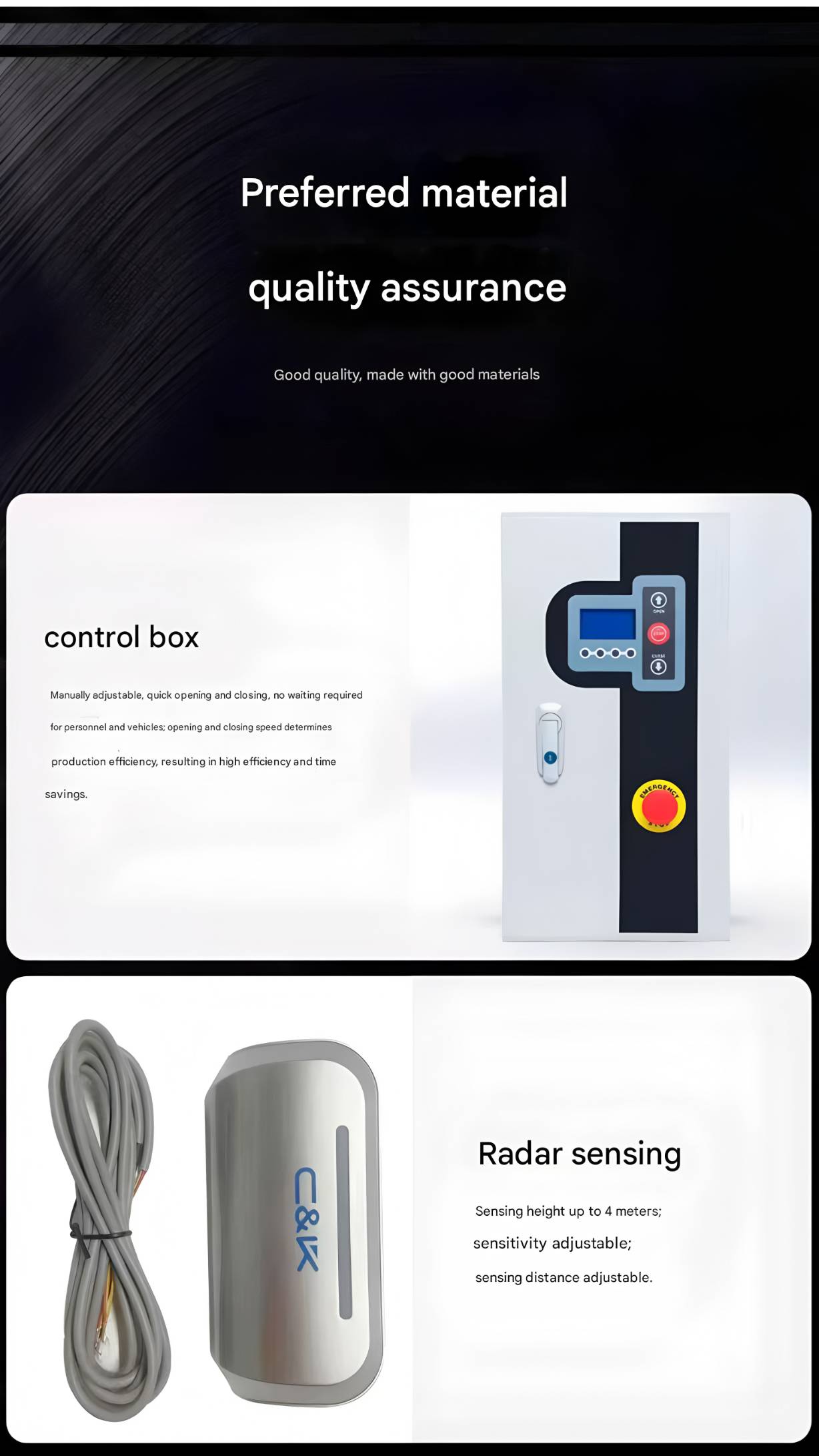

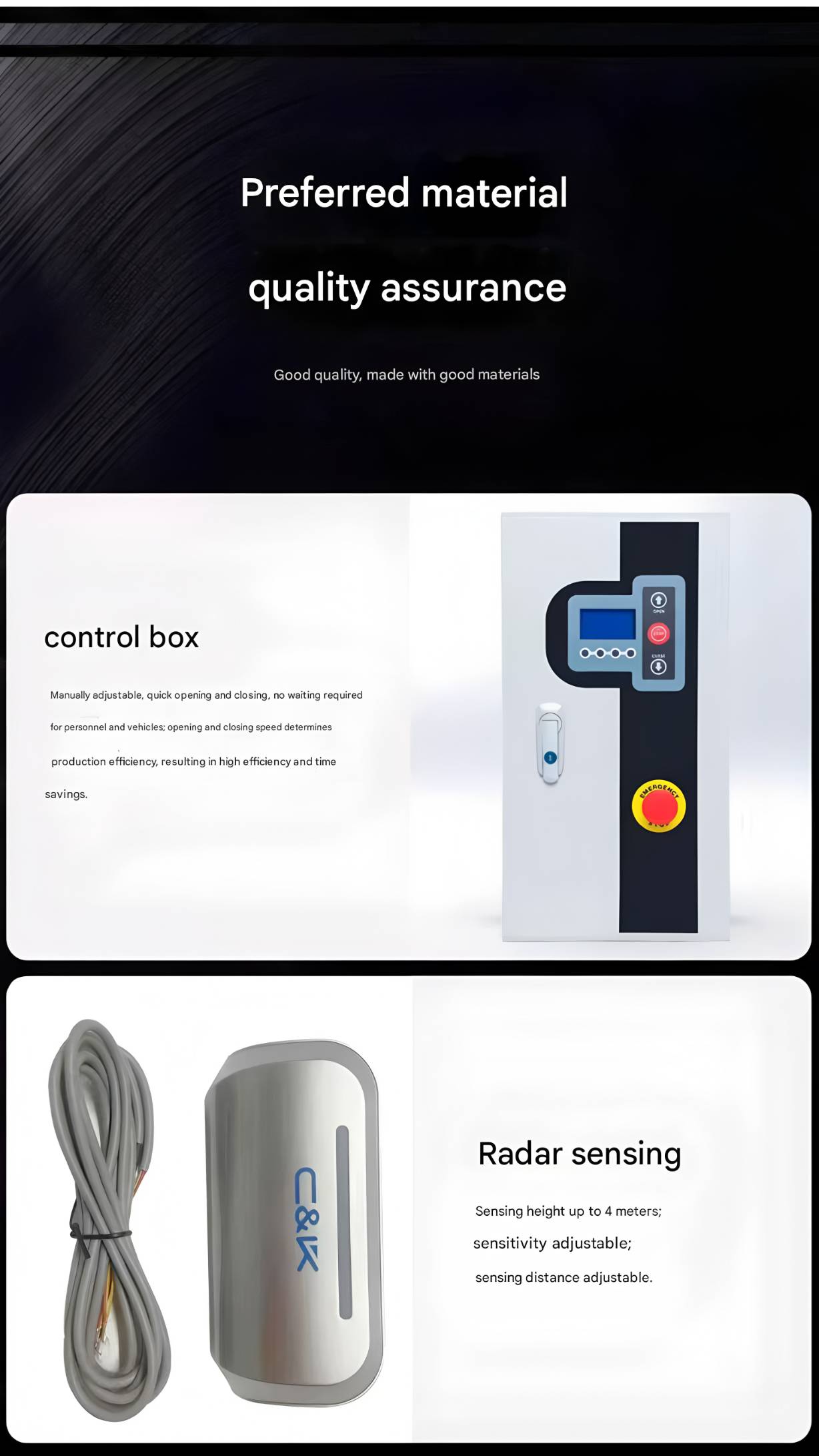

2.Intelligent Safety Protection

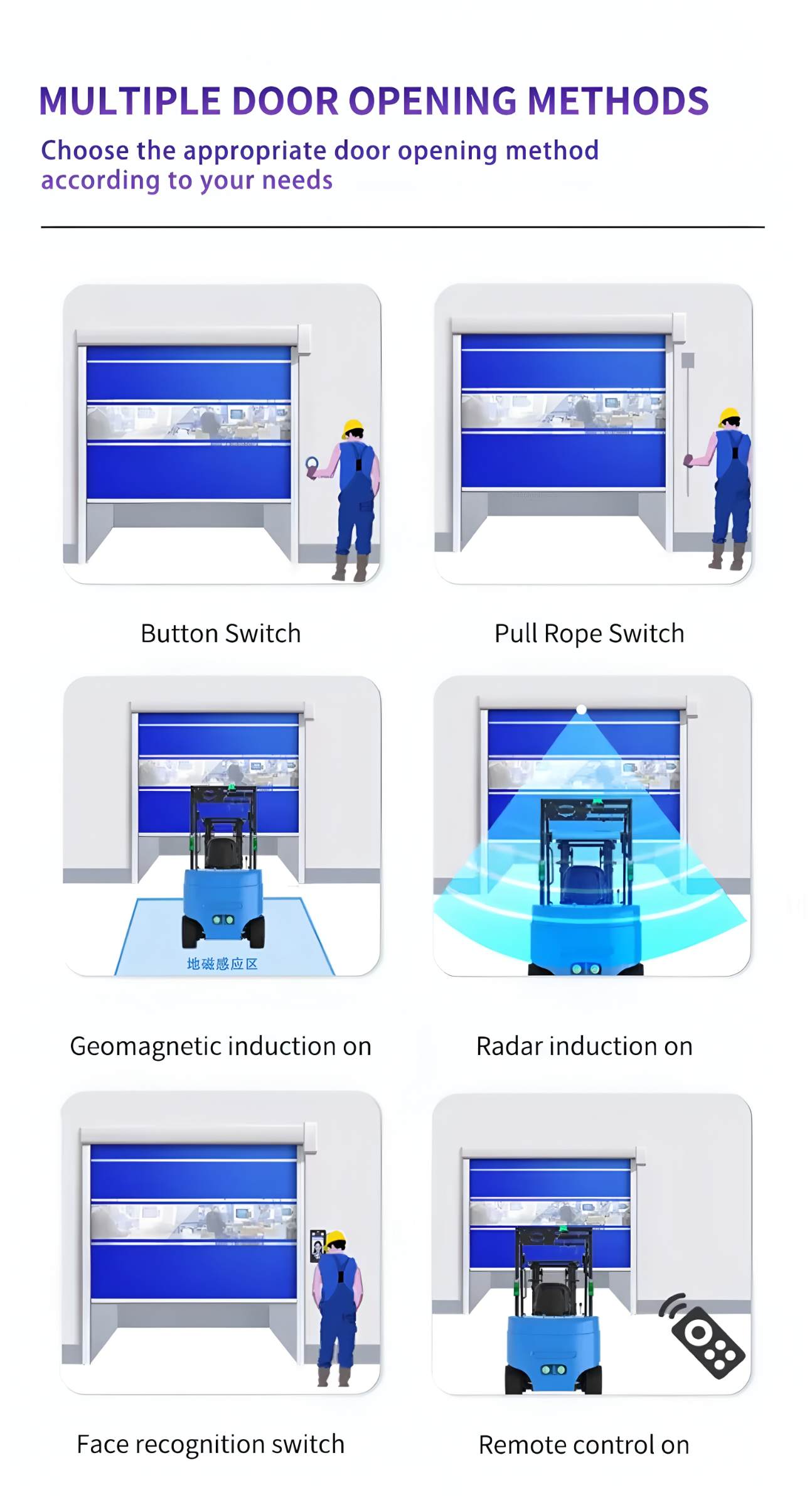

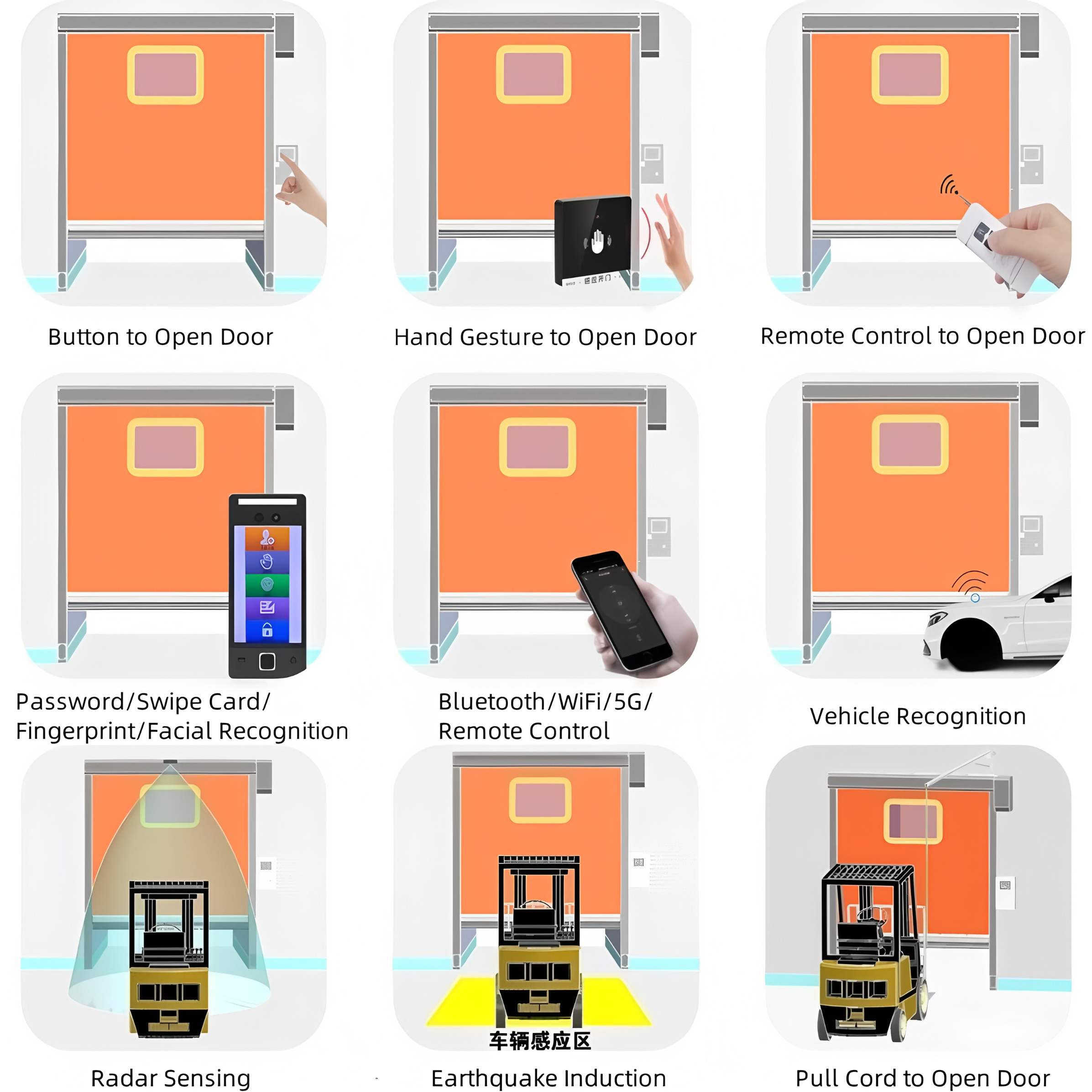

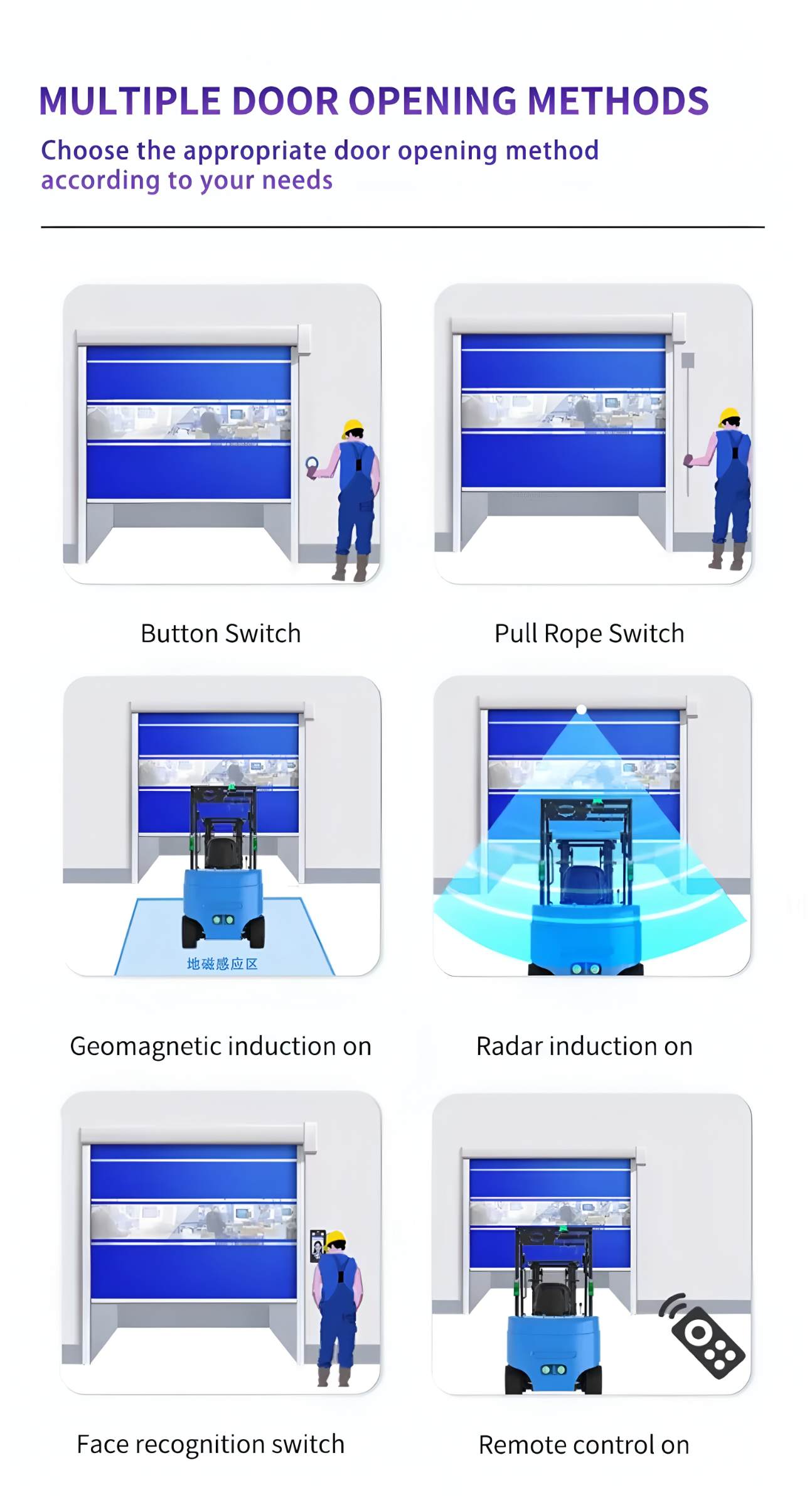

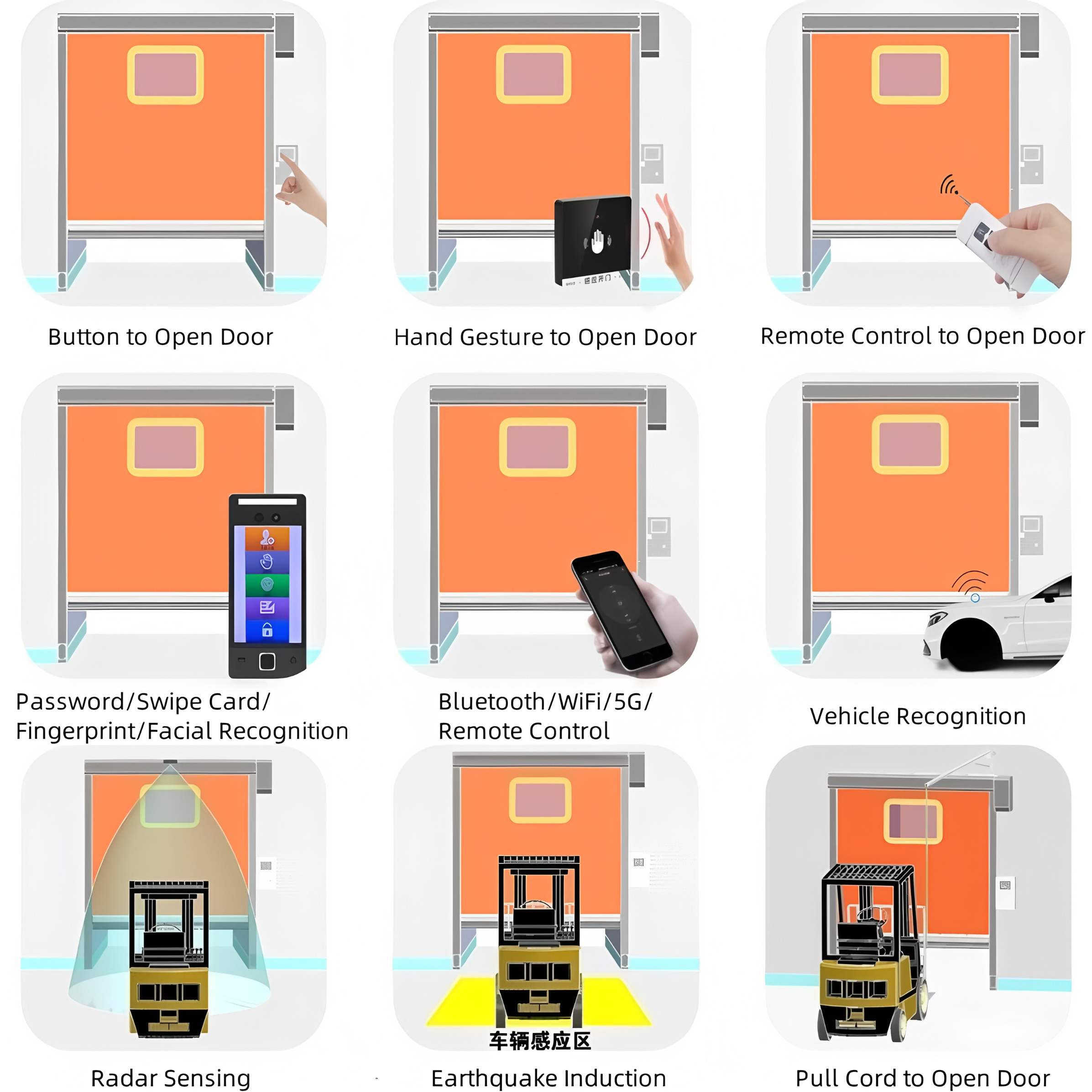

Standard dual-protection devices include infrared beam protection and a bottom safety airbag. The door automatically stops and reverses upon detecting obstacles. It supports various activation methods such as radar, ground sensors, remote controls, and pull cords, adapting to the automation needs of diverse industrial scenarios while ensuring safety for personnel and vehicles.

3.Excellent Sealing and Dustproof Performance

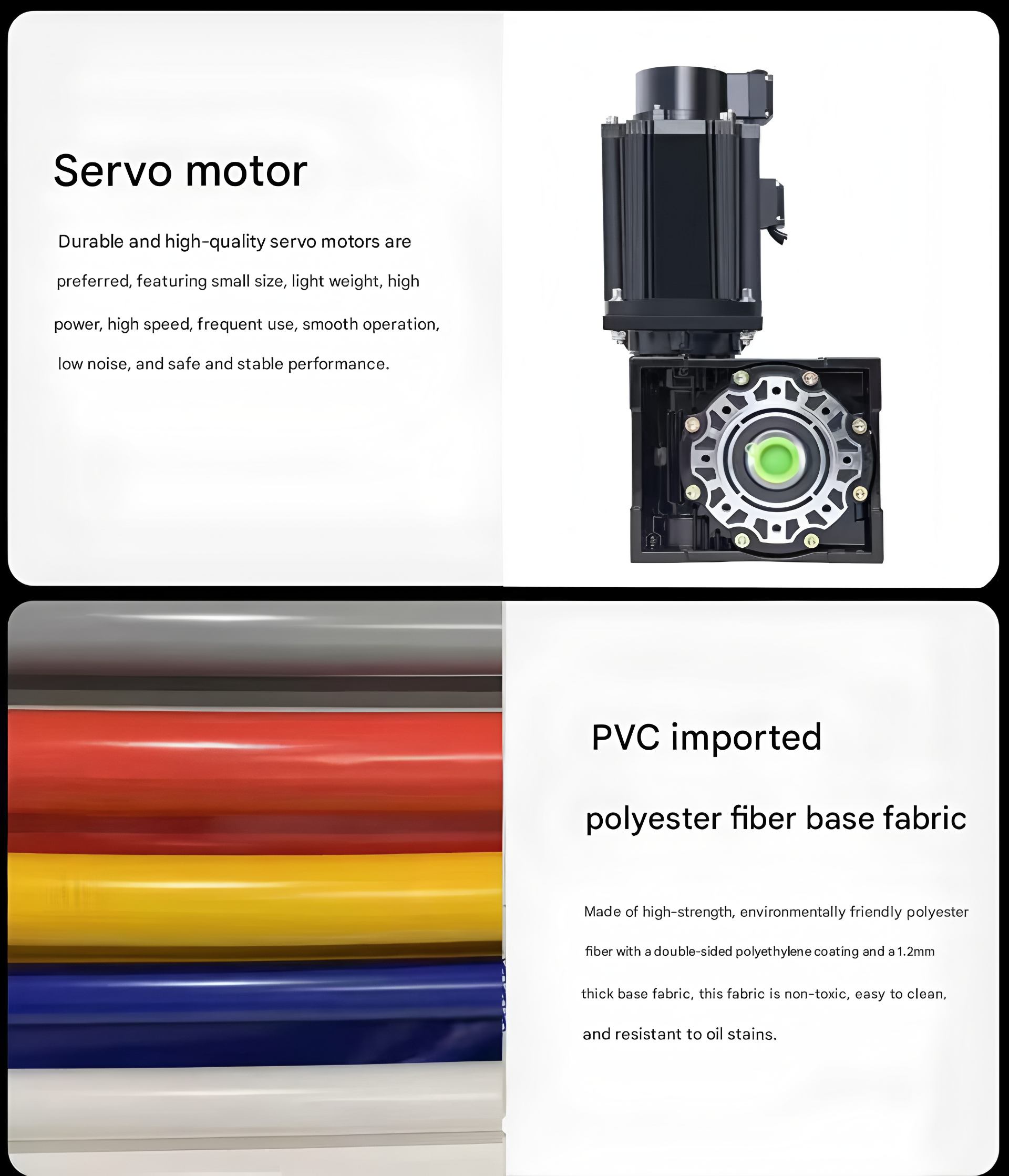

The door is equipped with high-density wear-resistant sealing strips on all sides, ensuring a tight fit between the frame and the door body. This effectively blocks dust, insects, odors, and thermal convection. The curtain is made of tear-resistant PVC-coated fabric or rigid aluminum alloy panels, offering strong weather resistance and making it suitable for cleanrooms, warehouses, logistics facilities, and other environments with stringent requirements.

4.Sturdy, Durable, and Low Maintenance Costs

The door frame is constructed from high-strength steel, with a wind resistance rating of up to levels 8–10, suitable for harsh outdoor weather conditions. The drive system utilizes maintenance-free bearings and wear-resistant components, ensuring low failure rates. Daily maintenance involves only cleaning the curtain and inspecting sealing parts, significantly reducing long-term operational costs for enterprises.

5.High Flexibility and Customization

Customizable for oversized openings (width up to 30m, height up to 20m). Options include transparent windows, insulated layers, anti-static curtains, and other configurations tailored to different industrial needs. Compatible with PLC industrial control systems, it seamlessly integrates with automated workshop production lines for intelligent and coordinated management.

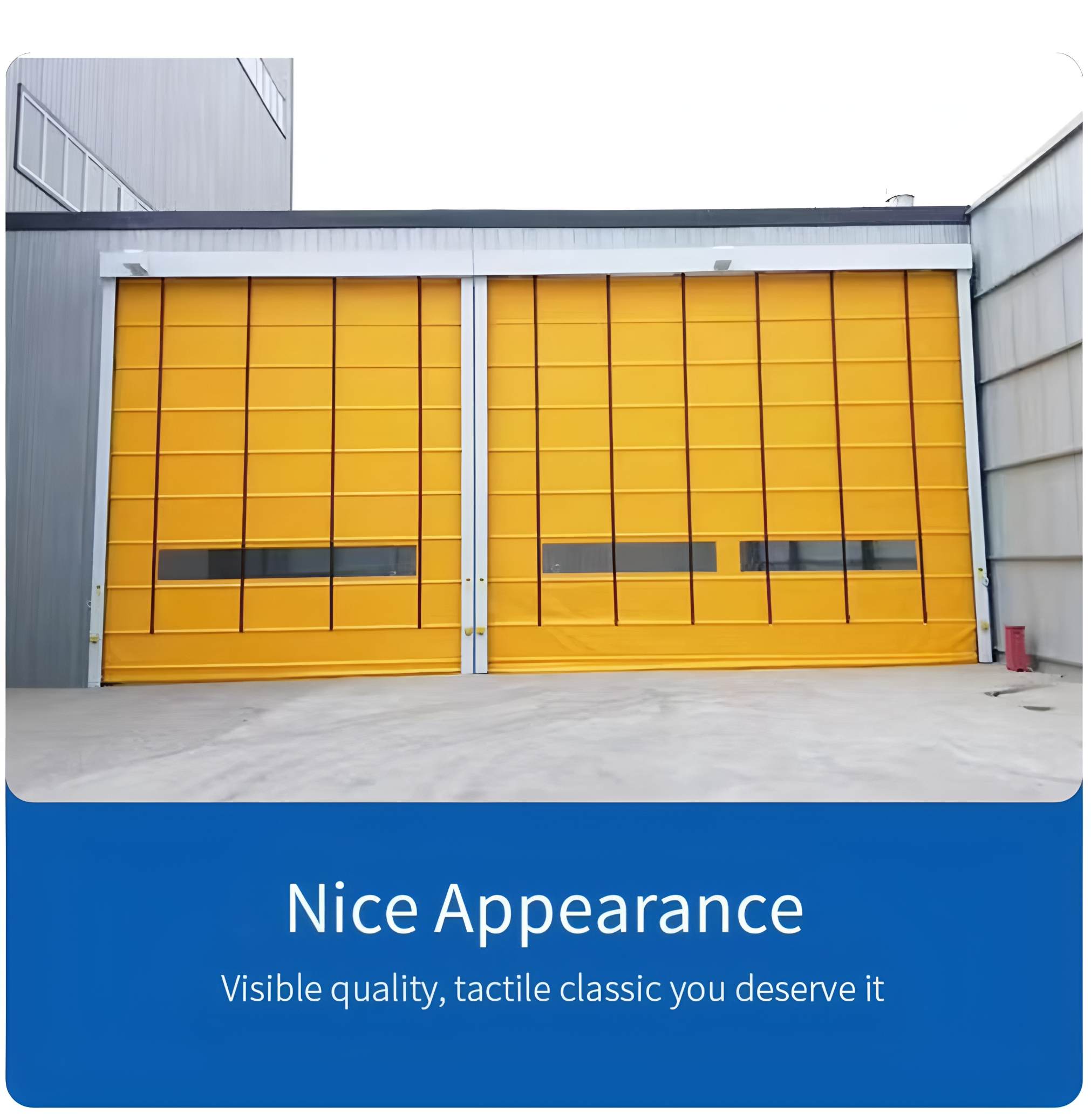

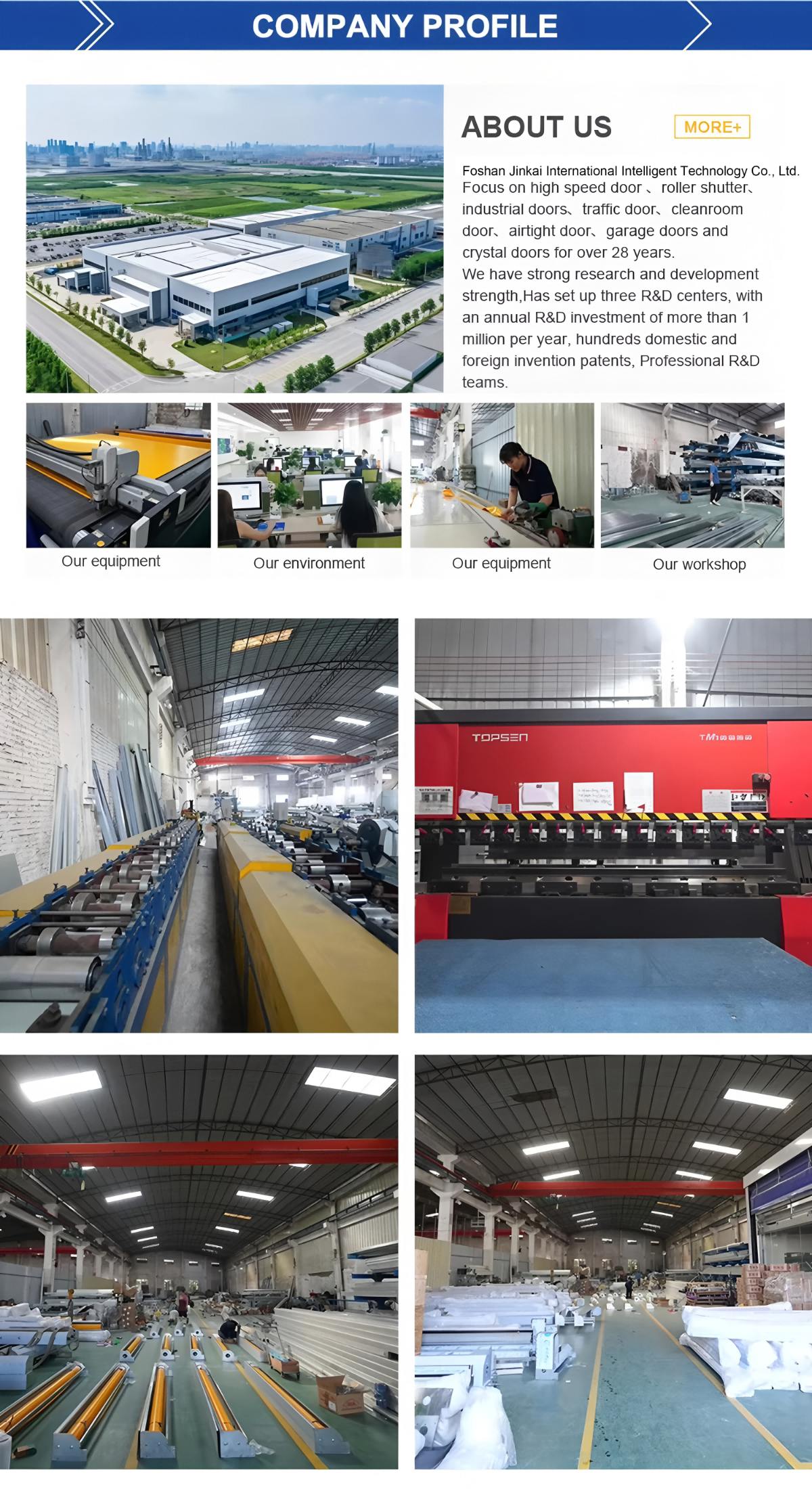

Product Description

This high-speed stacking door is an ideal partition solution for industrial logistics, cleanrooms, and storage facilities.

Driven by a servo motor and constructed from lightweight, high-strength materials, the door achieves an opening/closing speed of 0.8–1.5 m/s, supports high-frequency access, significantly improves logistics efficiency, and reduces energy loss. It comes standard with dual safety protection, including infrared beams and a bottom safety airbag, ensuring automatic bounce-back upon encountering obstacles for the safety of personnel and vehicles. High-density sealing strips around the door combined with wear-resistant curtains effectively block dust, insects, and thermal exchange, meeting both cleanliness and energy-saving requirements.

The door frame offers wind resistance of up to levels 8–10. The drive system features a high proportion of maintenance-free components, resulting in low failure rates and economical operational costs. It supports customization for oversized openings, with optional configurations such as transparent windows and insulated layers, and is compatible with PLC systems to adapt to diverse industrial scenarios.

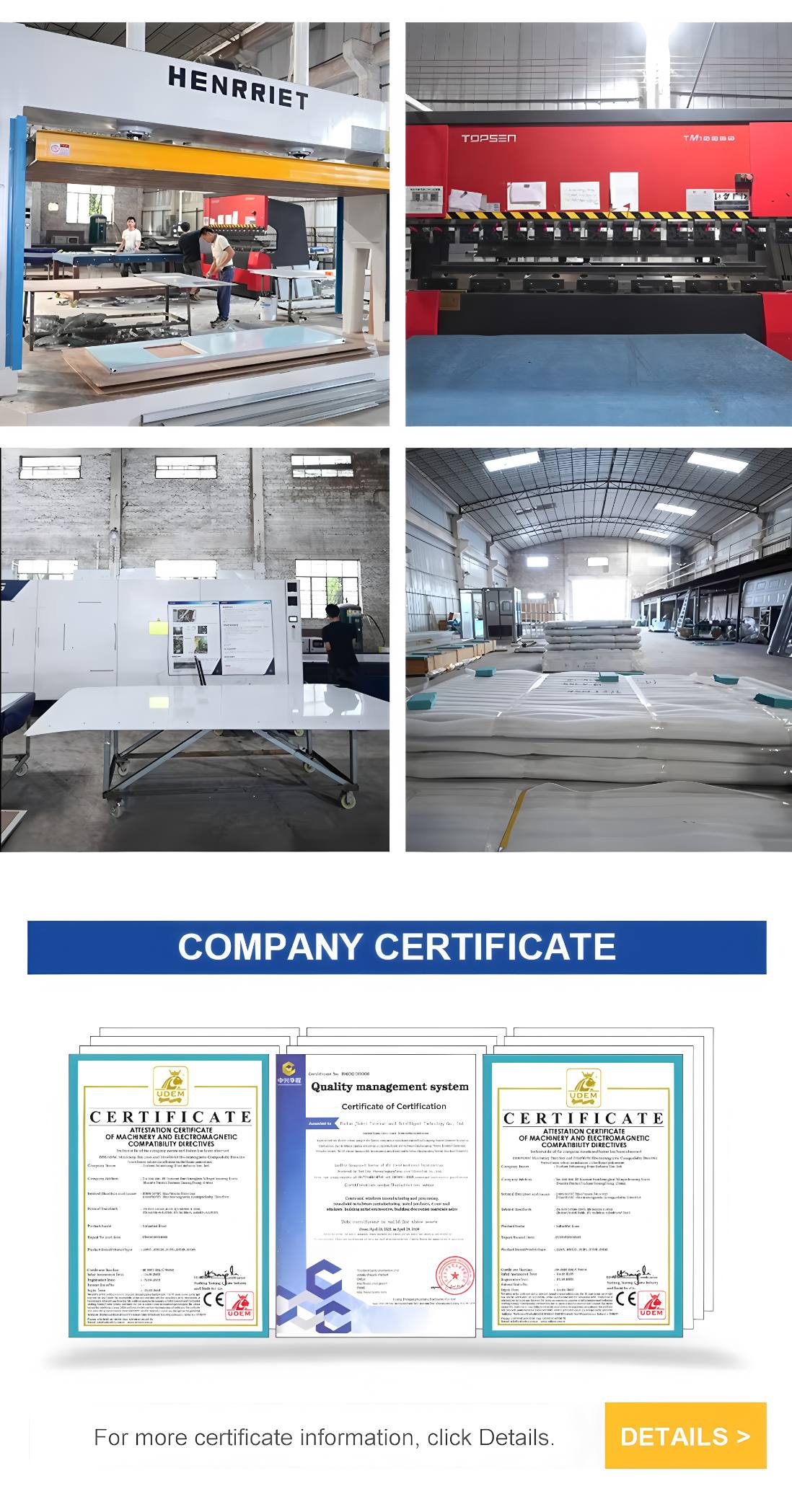

Production Process

Exhibition & Package & Shipping

Product Applications

1.Industrial Production Workshops

Suitable for partitioning indoor/outdoor workshop areas or dividing different production zones. Fast opening/closing reduces cross-contamination of dust and noise, while lowering air conditioning energy consumption. Particularly ideal for high-traffic scenarios such as automotive manufacturing, electronic components, and machining.

2.Warehousing and Logistics Centers

Designed for loading/unloading passages and storage zone entrances/exits. High-speed operation improves the passage efficiency of forklifts and trucks. The sealed, dust-proof structure protects goods from moisture and dust erosion, making it suitable for cold chain warehouses, e-commerce sorting centers, and similar facilities.

3.Cleanrooms and Dust-Free Workshops

Meets the cleanliness requirements of industries such as pharmaceuticals, food processing, and precision instrument manufacturing. Effectively isolates external pollutants and maintains a constant indoor temperature and humidity environment. Compatible with sensor-based activation for unmanned access control.

4.Cold Chain and Constant-Temperature Warehousing

Rapid opening/closing reduces heat and cold air exchange. Combined with insulated curtain configurations, it minimizes energy loss in cold storage and climate-controlled warehouses, ensuring the quality of temperature-sensitive goods such as fresh produce and pharmaceutical cold chain items.

5.Underground Garages and Commercial Parks

Suitable for underground garage entrances/exits and commercial logistics passages. Features wind resistance and wear resistance to adapt to outdoor or semi-outdoor environments. Intelligent sensor activation enhances vehicle passage efficiency while providing sound insulation and dust prevention.

After-sales Service

1. Free Installation, Commissioning, and Training

A professional technical team will provide free on-site installation and commissioning of the door body and control system to ensure all operating parameters meet usage standards. Additionally, one-on-one operational training will be offered to logistics and equipment management teams, covering daily start-stop procedures, linkage settings, basic troubleshooting, and more. Operation manuals and maintenance guides will be provided for reference.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire machine is covered by a 1-year warranty. During the warranty period, non-human damage faults will be repaired free of charge, and replacement parts will be provided at no cost.

3. Regular Inspections and Preventive Maintenance

During the warranty period, technical personnel will conduct on-site inspections every 6 months to check the door body’s sealing performance, sensor sensitivity, motor operation status, and other aspects. Worn-out components (e.g., brush seals) will be promptly replaced to prevent potential faults. After the warranty period ends, customers can sign an annual maintenance agreement to enjoy discounted inspection services and priority repairs, extending the service life of the door body.

4. Sufficient Spare Parts Inventory

Ensures timely supply of maintenance parts.

5. Lifetime Technical Support and Upgrade Services

Lifetime free technical consultation is provided to address various issues encountered during use. If upgrades to the door body’s linkage functions are required in the future (e.g., integration with new access control or fire protection systems), cost-price technical upgrade services are available to meet the hospital’s intelligent renovation needs.

FAQS

Q: What should I do if the door is jammed or slides unevenly?

A: First, clean any debris such as dust or gravel from the track, then apply specialized lubricant to the wheels and track. Check whether the door panel is aligned with the track and adjust its position promptly if misaligned.

Q: Why is the motor of the electric stacking door not starting?

A: First, check whether the power supply and wiring are normal to rule out power failure or short circuit issues. If the wiring is normal, the problem may be a faulty run capacitor, electromagnetic coil, or limit switch. Replace the damaged component or polish the contacts accordingly.

Q: What should I do if the door cannot fully close or open?

A: Check whether the door panel or track is deformed. If deformation is present, adjust or replace them accordingly. For automatic doors, troubleshoot the electrical control system and the working status of the sensors. Additionally, adjust the gap between the door panel and track to avoid excessive or insufficient clearance affecting operation.

Q: How can I resolve the issue of the door automatically sliding after installation?

A: This is likely due to the track tilting forward by more than 0.5°. Adjust the T-shaped adjusting screw indicated in the installation diagram. For newly installed doors, it might be caused by the omission of the anti-reverse buckle in the wheel set. Refer to the installation diagram and add the positioning pin accordingly.

Q: Which material should I choose for the stacking door based on different scenarios?

A: For high-frequency passage scenarios, choose 1.0mm galvanized steel with polyurethane foam filling for stronger impact resistance. For medium to low-frequency passages, opt for double-layer co-extruded PVC for lower five-year maintenance costs. For chemical zones, use fluorocarbon-coated aluminum alloy for better corrosion resistance.

Q: What daily maintenance tasks are required?

A: Clean debris from the track and stains from the door curtain weekly. Tighten connecting bolts and lubricate guide wheels and transmission bearings monthly. Test the sensitivity of infrared sensors quarterly. Have a professional inspect the motor and wiring annually.

Q: What safety regulations should be observed during use?

A: When the door is operating, do not allow personnel or goods to remain underneath it. Vehicles should maintain a distance of at least 30cm from the guide rail. Do not disassemble safety components such as limit switches or sensors without authorization. When using the manual emergency device during a power outage, apply force evenly and steadily.

Procurement advantages

1.Outstanding Cost-Effectiveness with Controllable Overall Costs

The door's core components feature a maintenance-free design, resulting in low failure rates and significantly reduced long-term repair and labor costs. Compared to traditional industrial doors, it improves energy efficiency by 15%–20%, delivering substantial savings in electricity expenses over time.

2.Customizable to Meet Diverse Needs

Supports personalized customization for oversized openings, material thickness, and functional configurations. Optional components such as transparent windows, insulated layers, and anti-static curtains are available, ensuring a perfect fit for various scenarios like workshops, warehouses, and cleanrooms.

3.Comprehensive Safety Protection, Compliant with Industry Standards

Equipped with dual anti-pinch devices: infrared beams and a bottom safety airbag, ensuring automatic rebound upon encountering obstacles. The electrical system meets industrial safety protection standards and can be integrated with workshop PLC automation systems to ensure safety for personnel and equipment during operation.

4.Easy Installation with Minimal Downtime

The modular design allows for straightforward on-site assembly without the need for extensive structural modifications. Professional installation teams ensure rapid delivery, minimizing disruptions to production and warehousing operations.