Product Feature

1.High-Speed Operation

The door opens and closes rapidly, typically at a speed of 0.6 meters per second or higher. This allows for quick completion of opening and closing actions, effectively reducing waiting time and improving passage efficiency.

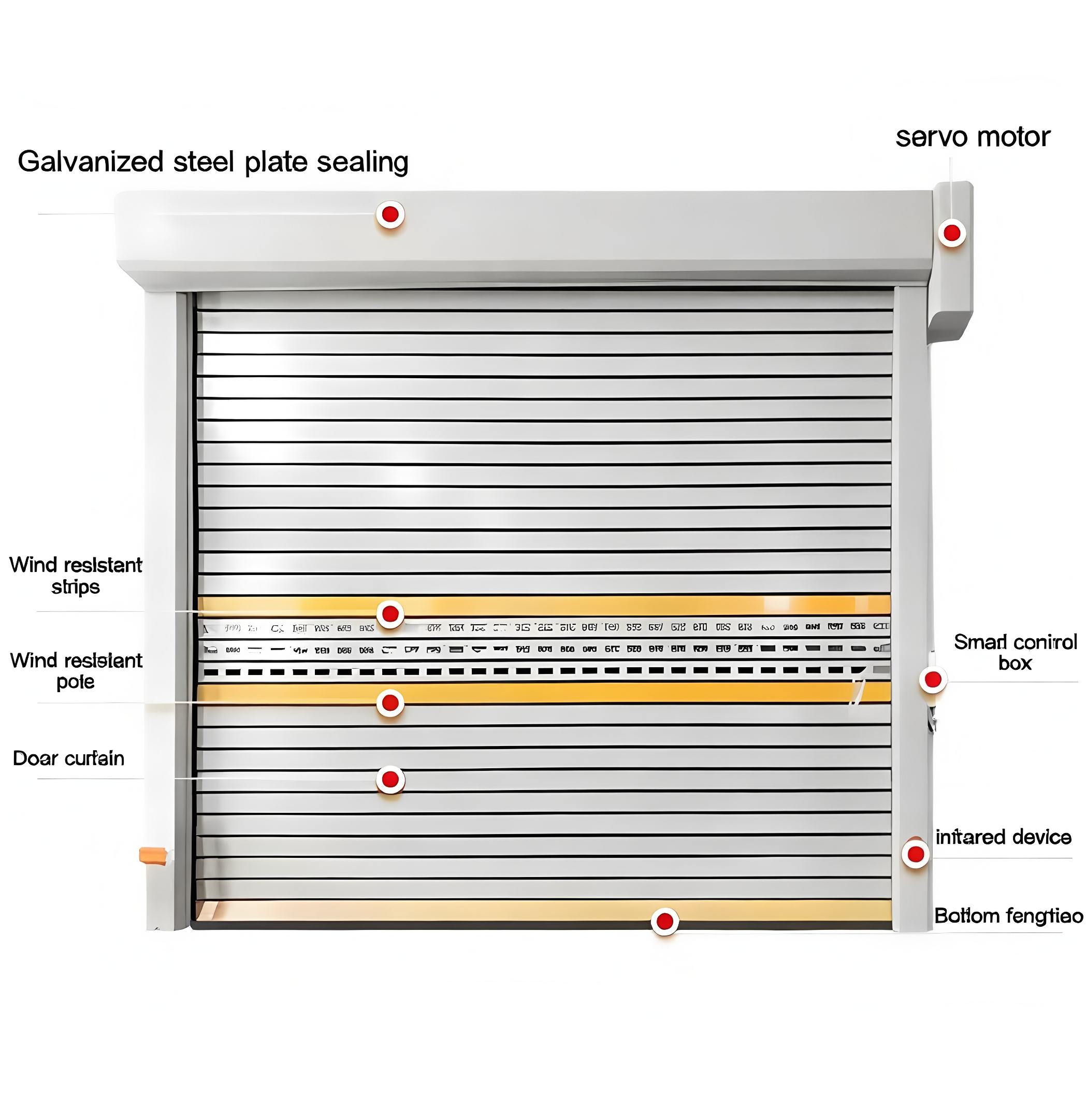

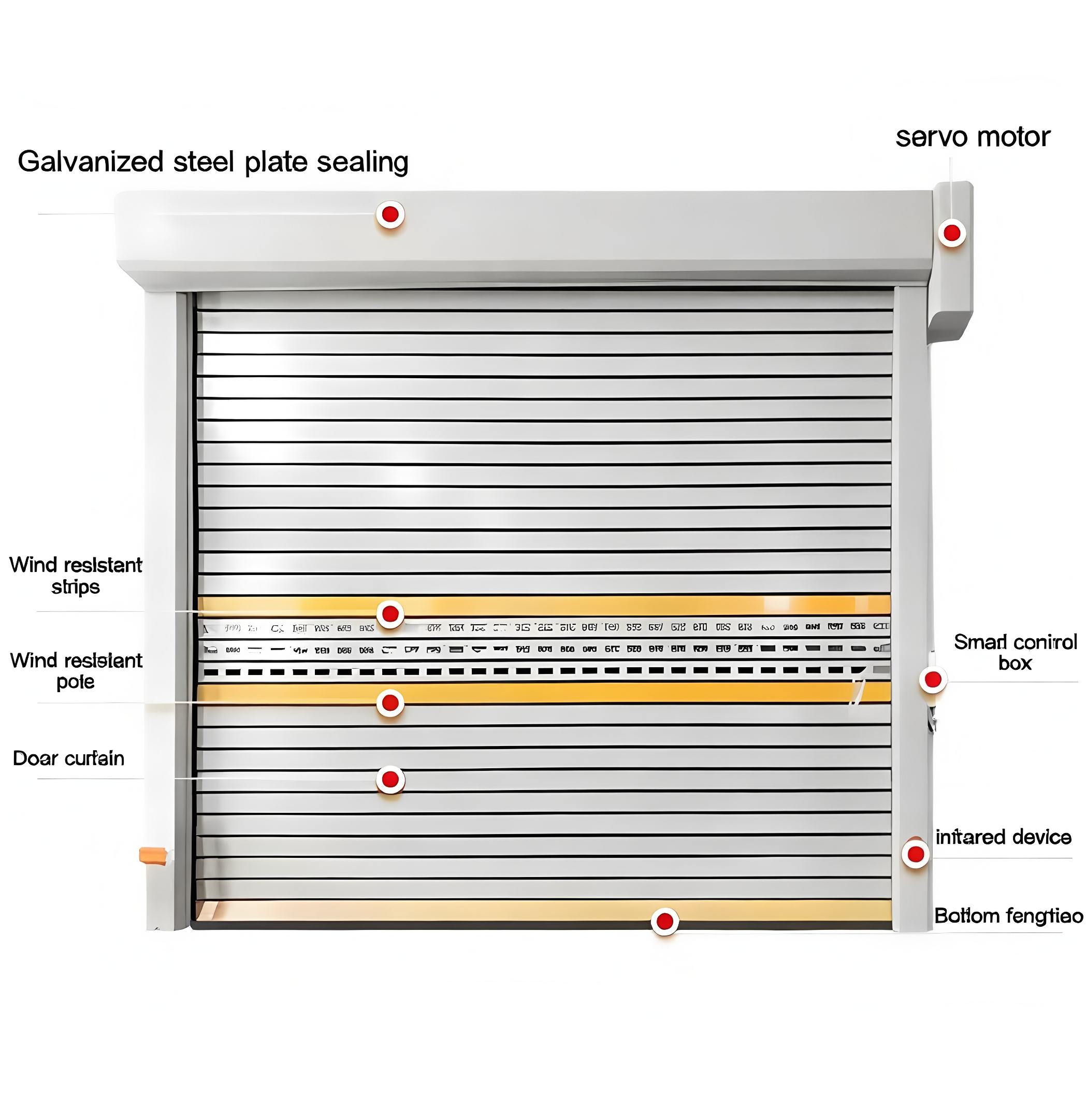

2.Excellent Sealing Performance

The edges of the door panels are equipped with sealing strips that tightly fit against the door frame, effectively isolating the external environment. This helps maintain internal temperature while reducing the entry of dust, insects, and other contaminants.

3.Sturdy and Durable

Made from high-quality metal materials or high-strength aluminum alloy and PVC composites, these doors exhibit exceptional hardness and impact resistance. They can withstand frequent operation and significant external force impacts, ensuring a long service life.

4.Smooth Operation

Featuring specially designed hinges and guide rail systems, the door panels can stack and unfold smoothly. The roller design also helps minimize shaking during operation, reducing its impact on the surrounding environment.

5.Safe and Reliable

Equipped with multiple safety devices, such as photoelectric sensors, anti-drop mechanisms, and emergency stop buttons, these doors can promptly detect obstacles during operation, preventing accidents and ensuring the safety of people and property.

6.Energy-Efficient and Eco-Friendly

The fast opening and closing functionality reduces the time the door remains open, minimizing the frequency of air exchange between indoors and outdoors. Combined with excellent sealing performance and the use of insulation materials, this contributes to energy savings and lower operational costs.

7.Low Noise Level

The door generates minimal noise during operation, ensuring it does not significantly disrupt the surrounding work environment. This makes it particularly suitable for noise-sensitive settings.

8.High Customizability

These doors can be customized according to user requirements in terms of size, color, design, and control methods, meeting the needs of various door openings and diverse environmental conditions.

9.Easy Installation and Maintenance

The overall structure is simple in design, making installation relatively straightforward. Daily maintenance and upkeep are also easy, effectively reducing usage costs and maintenance efforts.

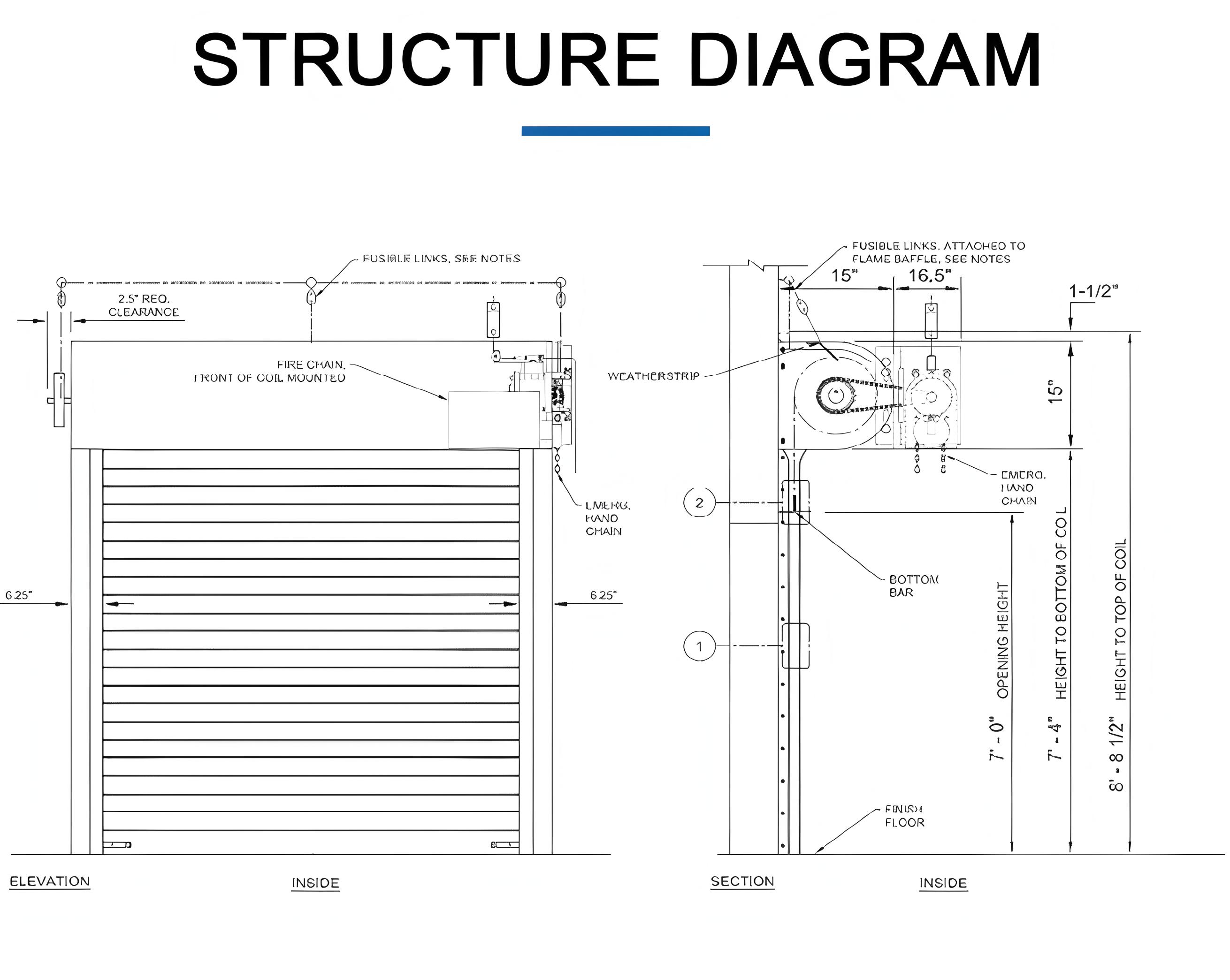

Product Description

Roller Hard High-Speed Door: The Optimal Solution for Efficient Passage and Environmental Control in Industrial Settings

The roller hard high-speed door is an ideal solution for enhancing operational efficiency and environmental management in industrial scenarios. Constructed from high-strength hard alloy materials and integrated with a precision roller winding system, the door achieves an opening speed exceeding 0.6m/s, significantly reducing opening and closing times and improving logistics turnover efficiency.

The door frame is equipped with high-sealing strips, effectively isolating dust, wind, rain, and the exchange of hot and cold air, while providing dustproofing, thermal insulation, and energy-saving benefits. Operating smoothly and quietly, the door is also fitted with multiple safety features, including photoelectric sensors and anti-drop mechanisms, ensuring the safety of personnel and equipment. Customization options for dimensions, colors, and control methods are available, making it suitable for a wide range of industrial environments such as factories, warehouses, and clean rooms.

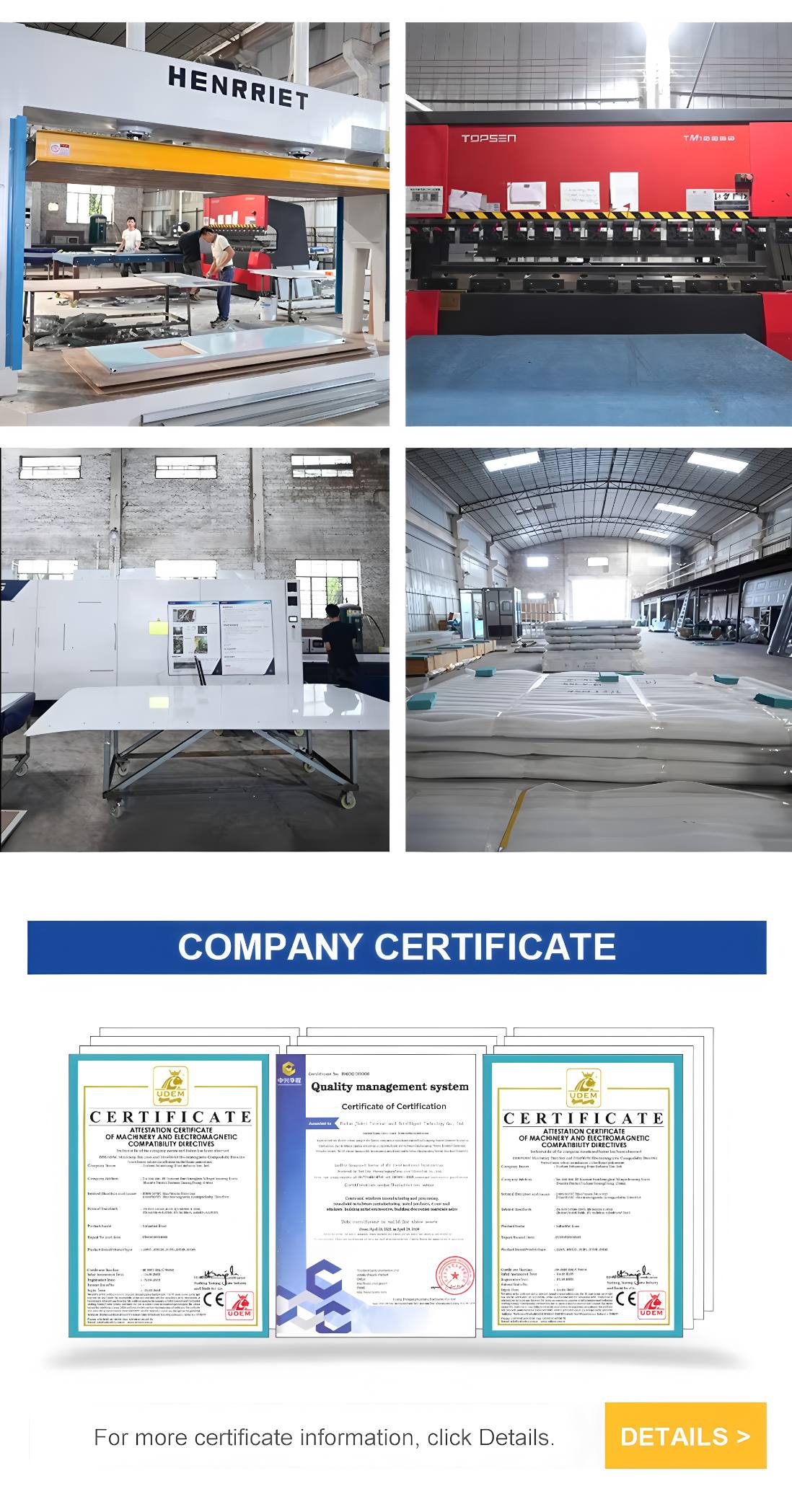

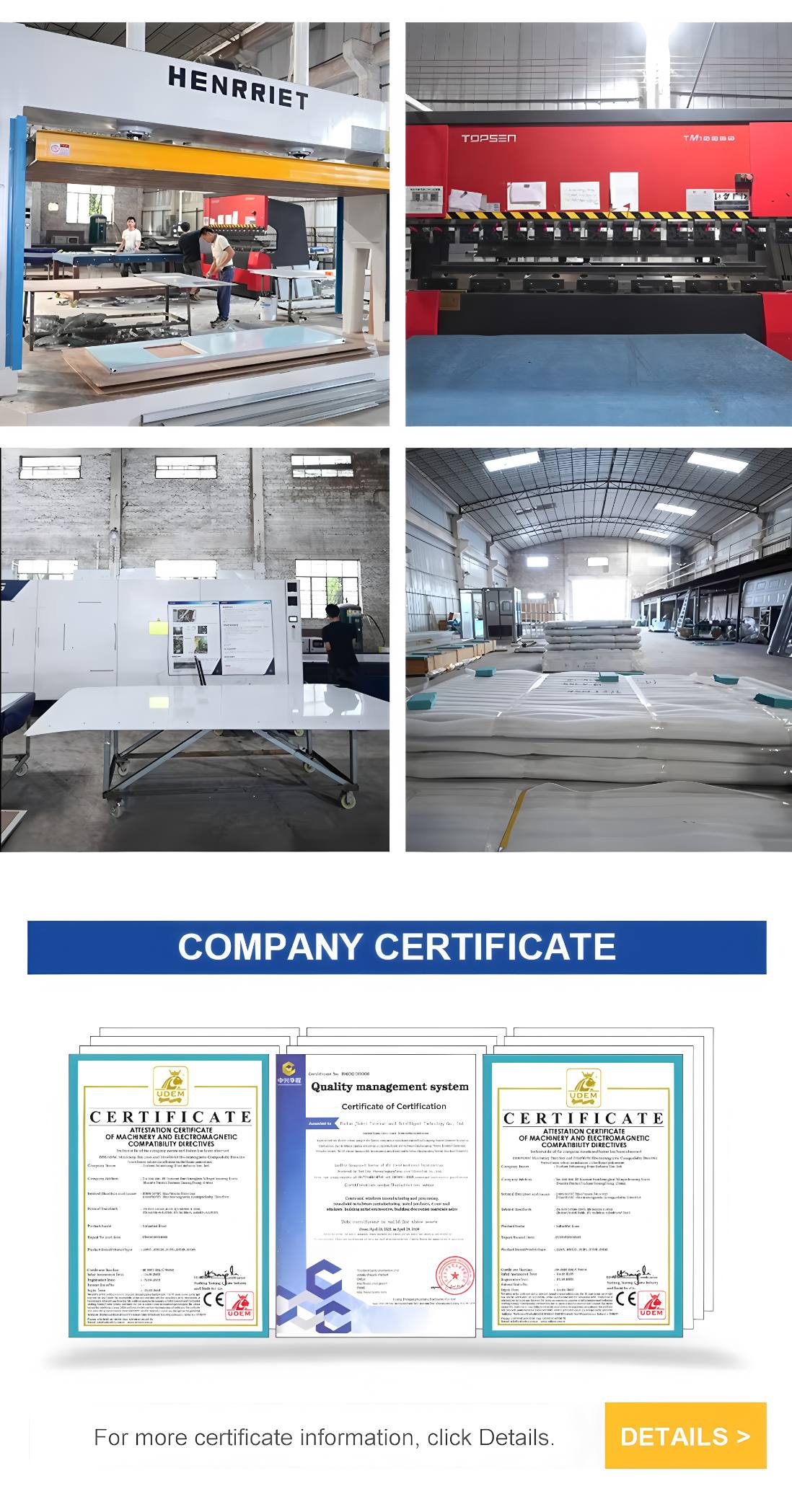

Production Process

Exhibition & Package & Shipping

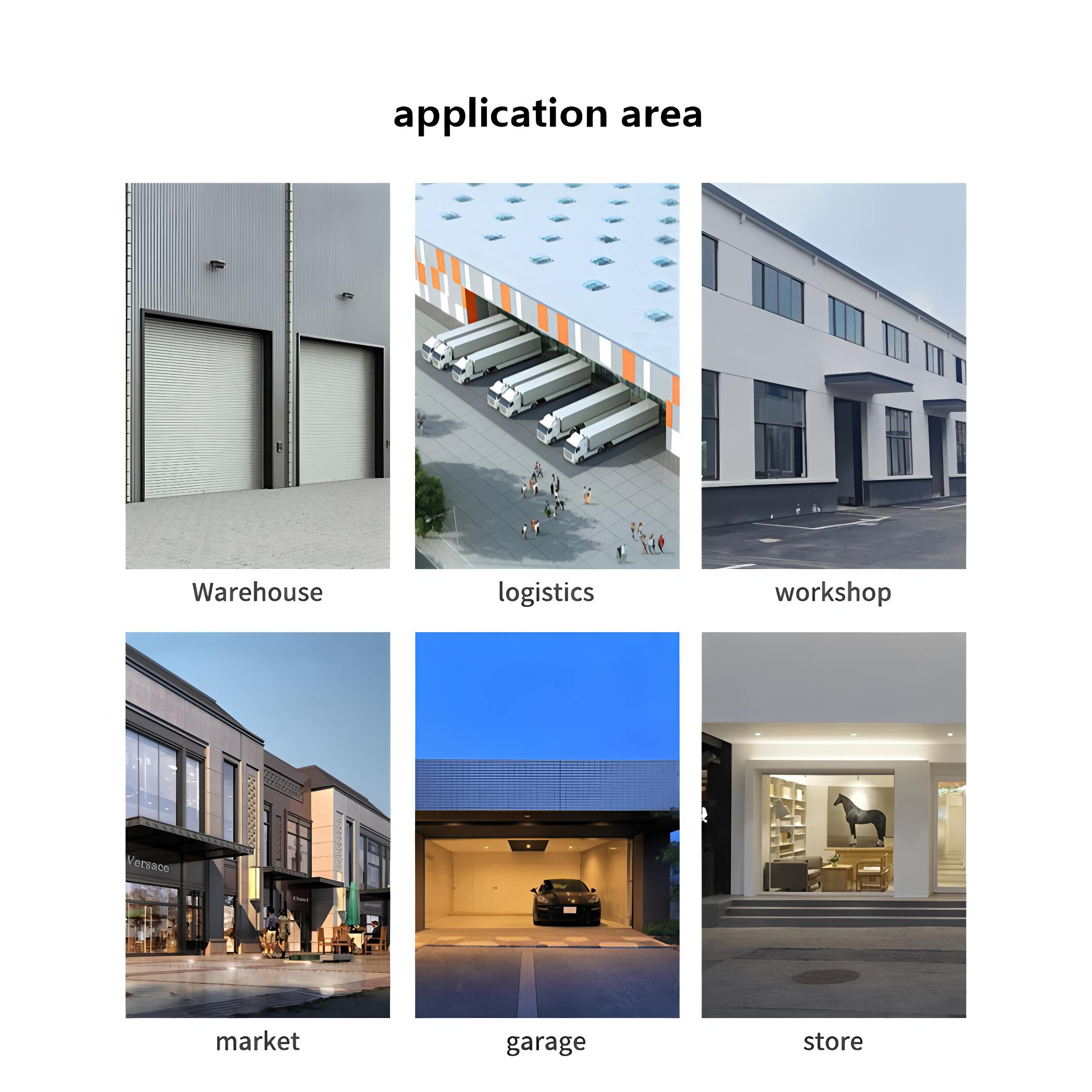

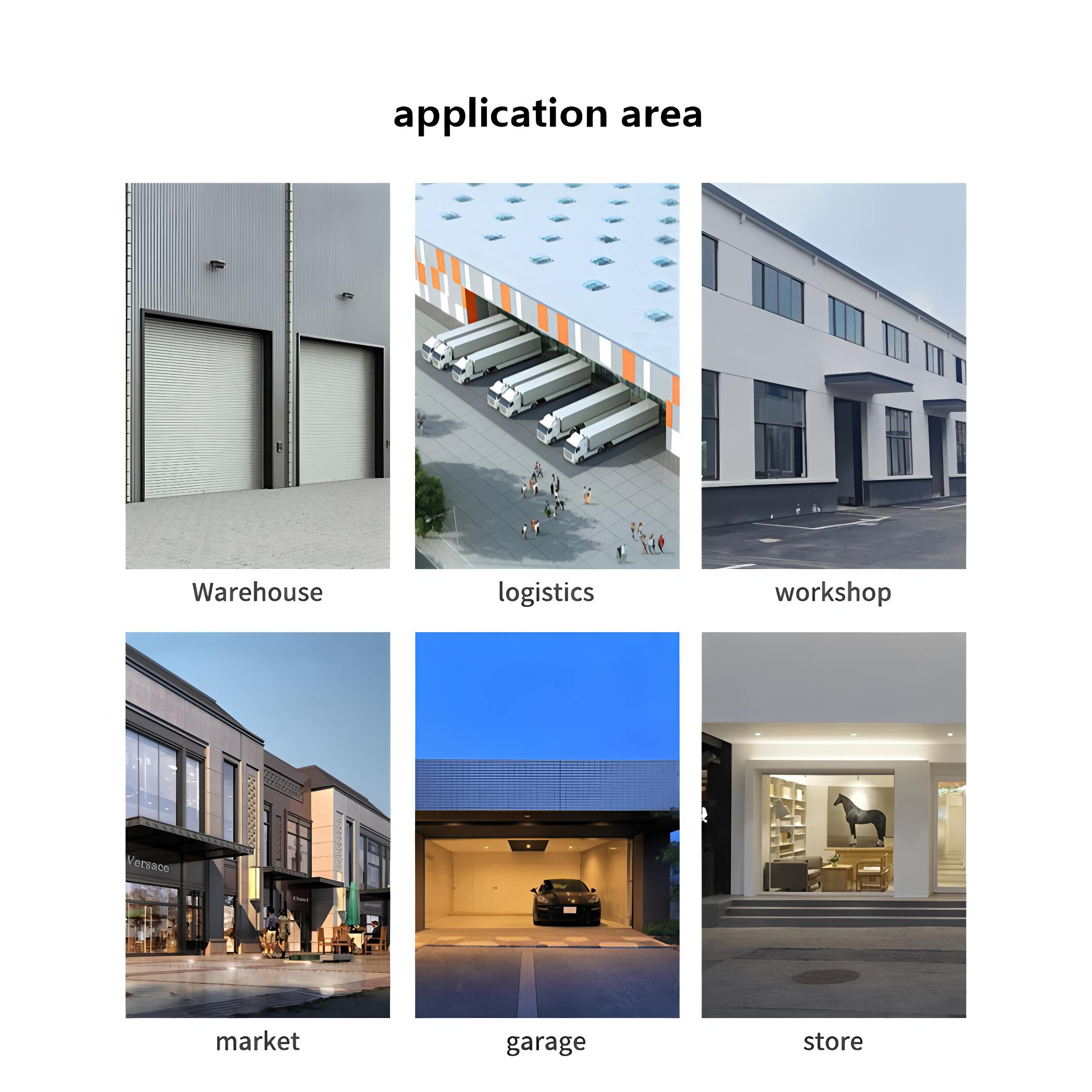

Product Applications

1. Industrial Plants / Workshops

Used as partition doors for raw material warehouses, production workshops, and finished product storage areas, ensuring rapid access while reducing temperature differences and dust exchange between indoor and outdoor environments. Suitable for frequent forklift and truck traffic.

2. Logistics and Warehousing Centers

Ideal for loading/unloading zones and sorting area passageways. The high-speed opening and closing enhance cargo turnover efficiency, while the sealing performance protects the storage environment from rain and dust intrusion.

3. Cold Chain / Cleanrooms

Suited for cold storage, constant-temperature warehouses, pharmaceutical cleanrooms, and food processing workshops. Rapid operation minimizes loss of cold or clean air, reducing energy consumption while meeting hygiene and environmental control requirements.

4. Automotive Manufacturing / 4S Shops

Applied in painting workshops, assembly lines, and maintenance passages to isolate paint dust and noise, ensuring a clean production environment. Compatible with heavy equipment passage.

5. Commercial Logistics Hubs

Perfect for e�commerce distribution centers and express delivery transit stations. High�frequency operation does not compromise logistics efficiency, and the robust door construction resists external impact, extending service life.

After-sales Service

1.Free Installation, Commissioning, and Training

A professional technical team will provide free on-site installation and commissioning of the door body and control system, ensuring all operating parameters meet usage standards. Additionally, one-on-one operational training will be offered to logistics and equipment management teams, covering daily start-stop procedures, linkage settings, simple troubleshooting, and more. Operation manuals and maintenance guides will also be provided.

2.Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) are covered by a 2-year warranty, while the entire machine is covered by a 1-year warranty. During the warranty period, non-human damage faults will be repaired free of charge, and replacement parts will be provided at no cost.

3.Regular Inspections and Preventive Maintenance

During the warranty period, technical personnel will conduct on-site inspections every 6 months to check the door body’s sealing performance, sensor sensitivity, motor operation status, and other aspects. Worn-out components (e.g., brush seals) will be promptly replaced to prevent potential faults. After the warranty period ends, customers can sign an annual maintenance agreement to enjoy discounted inspection services and priority repairs, extending the service life of the door body.

4.Adequate Spare Parts Inventory

Ensures timely supply of maintenance parts.

5.Lifetime Technical Support and Upgrade Services

Lifetime free technical consultation is provided to address various issues encountered during use. If upgrades to the door body’s linkage functions are required in the future (e.g., integration with new access control or fire protection systems), cost-price technical upgrade services are available to meet the hospital’s intelligent renovation needs.

FAQS

Q: Can the opening and closing speed of the roller hard high-speed door be adjusted?

A: Yes. The door control system supports custom speed parameter settings, allowing adjustments based on on-site traffic requirements and cargo types to balance efficiency and safety.

Q: Can the door operate normally during a power outage?

A: Yes. The door is equipped with a standard emergency manual mechanism or backup power supply. In the event of a power outage, the door can be easily opened or closed using a manual crank, or switched to backup power for electric operation, ensuring passage in emergencies.

Q: Is this door suitable for outdoor installation?

A: Yes. The door frame is treated with anti-corrosion coating, and the door panels are equipped with weather-resistant finishes to withstand rain, sun, and other outdoor environmental factors. The sealing strips also provide excellent waterproofing and dustproofing. For outdoor installation, proper drainage measures should be implemented.

Q: What should be noted in daily maintenance?

A: Regularly clean debris from the tracks to prevent jams; lubricate moving parts such as hinges and rollers; inspect the wear of sealing strips and replace aging components promptly; and periodically test safety sensors to ensure proper functionality.

Q: Will the door automatically stop if it encounters an obstacle?

A: Yes. The door is equipped with dual safety protection systems, including photoelectric sensors and pressure sensors. If an obstacle is detected, the door will immediately stop and reverse, effectively preventing collisions with personnel or equipment.

Procurement advantages

1.High-Efficiency Passage, Cost Reduction & Efficiency Improvement

Opening/closing speed exceeding 0.6m/s accommodates frequent forklift and truck access, reducing wait times inside/outside workshops or warehouses and enhancing logistics turnover efficiency.

2.Sealing & Energy Efficiency, Lower Operating Costs

Highly-sealed door frame strips combined with rapid opening/closing design minimize thermal exchange, reducing energy consumption in cold storage and temperature-controlled workshops.

3.Robust & Durable, Extended Service Life

Hard alloy door panels with anti-corrosion coated frames offer impact resistance and weather durability, suitable for complex indoor/outdoor environments while reducing replacement frequency.

4.Safety Protection, Accident Prevention

Standard multi-safety features including photoelectric sensors, anti-drop mechanisms, and obstacle-reverse functions ensure safe passage for personnel and equipment, lowering accident risks.

5.Flexible Customization, Adaptable to Diverse Scenarios

Customizable dimensions, colors, and control methods (manual/electric/remote) to meet requirements of factories, cold chains, cleanrooms, and other varied environments.

6.Easy Installation & Maintenance, Effortless Operation

Modular structural design ensures short installation time. Daily maintenance only requires track cleaning and lubrication, resulting in low upkeep costs without disrupting production schedules.