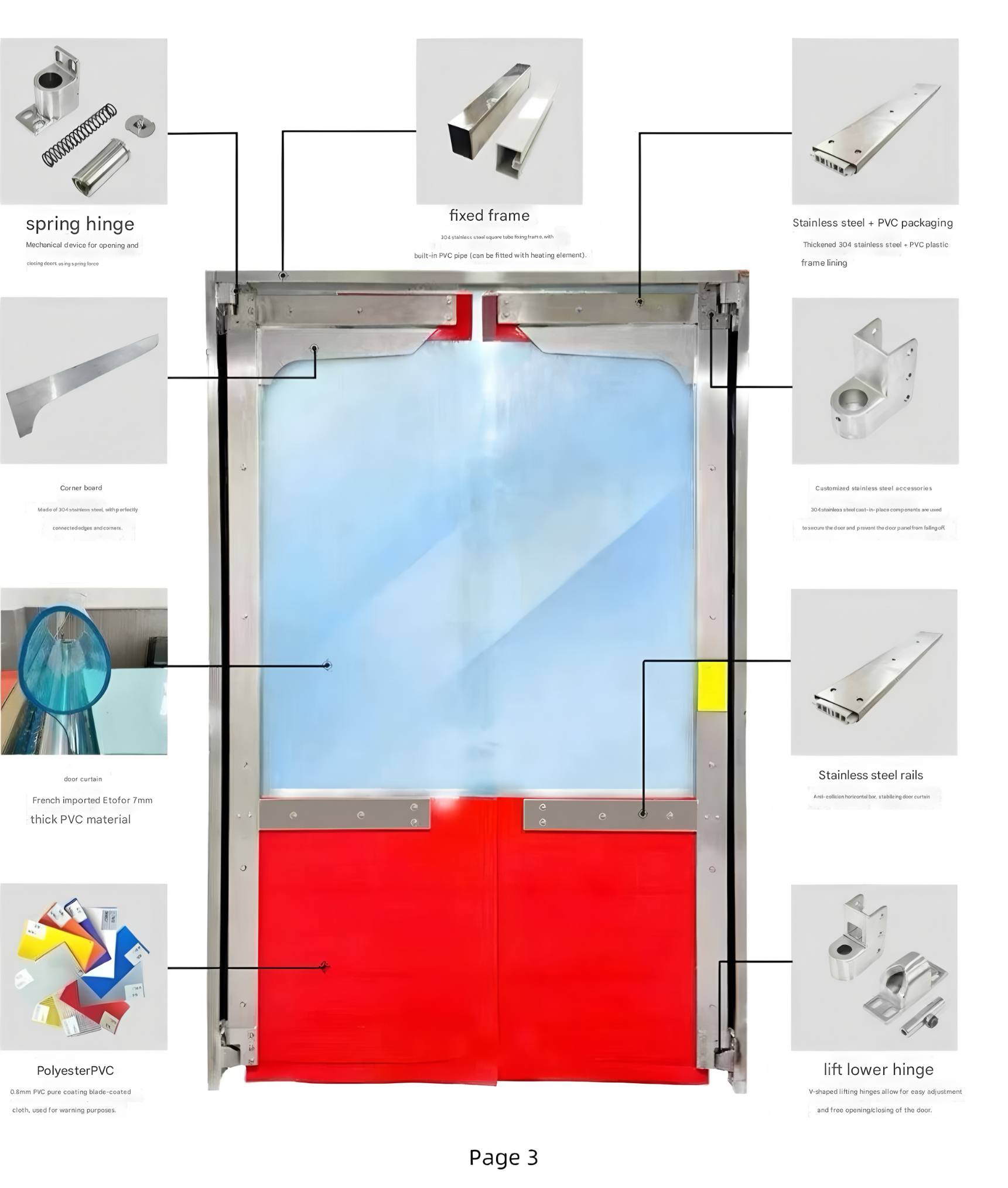

Product Feature

1. Impact-Resistant and Resilient

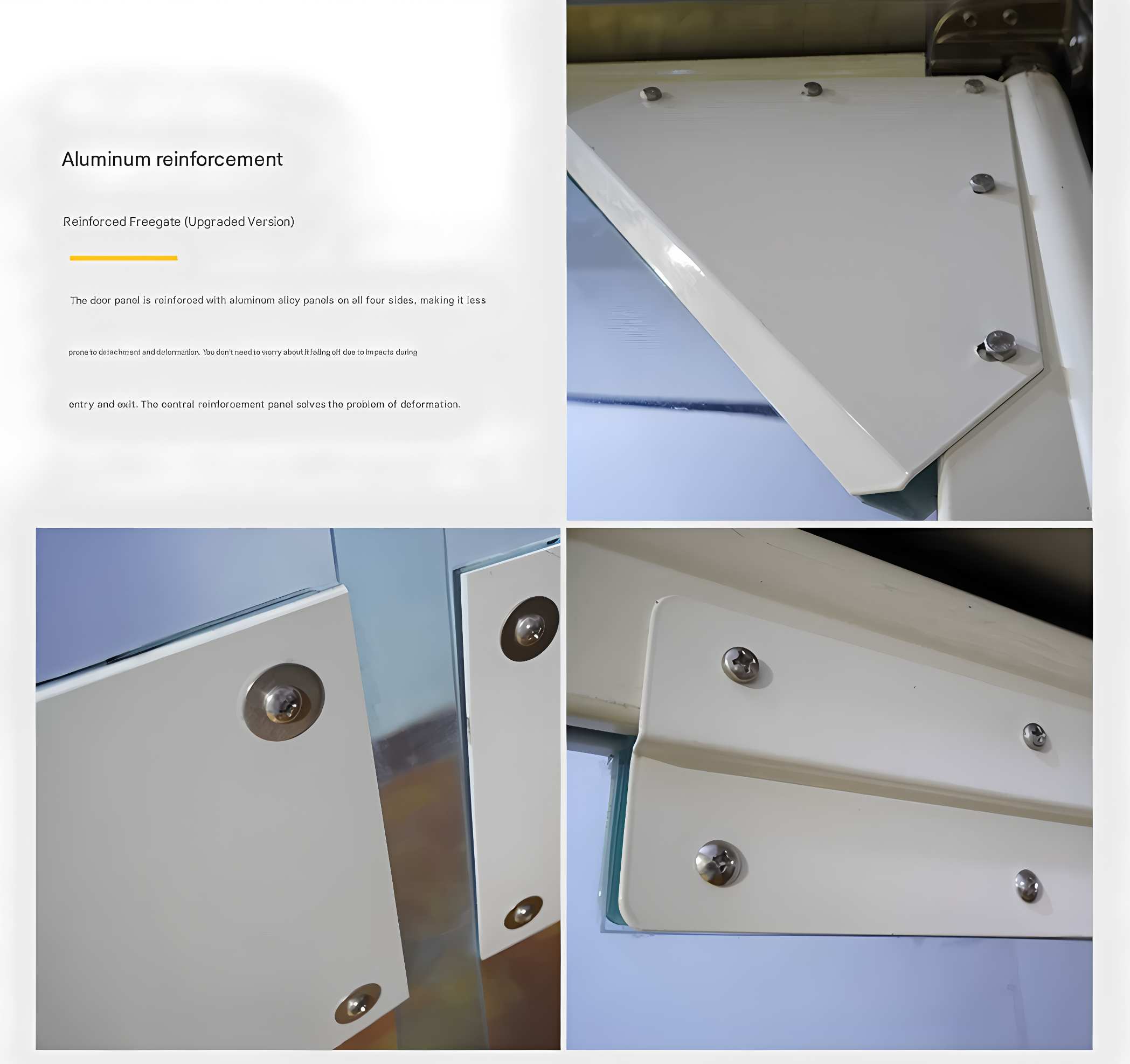

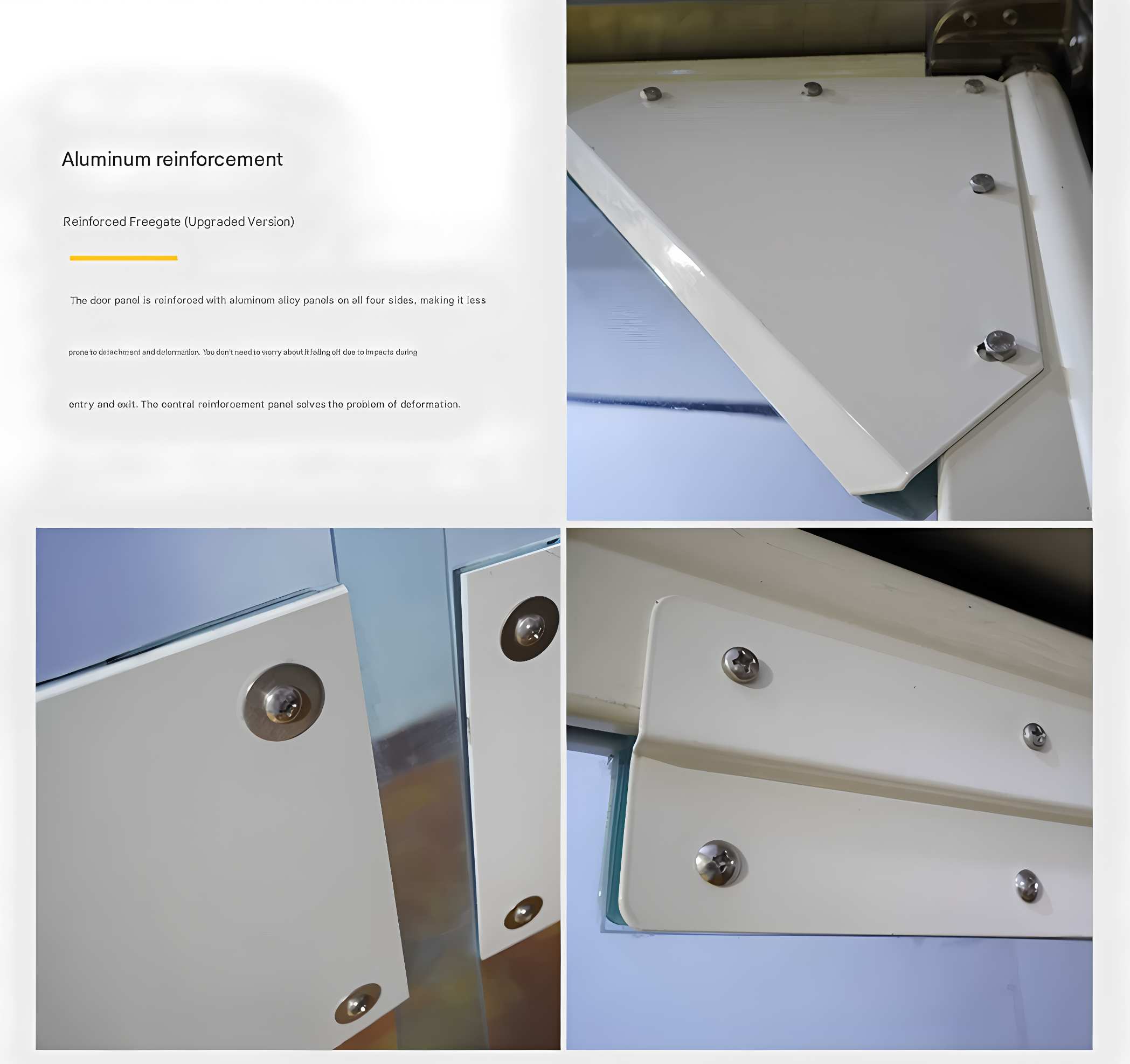

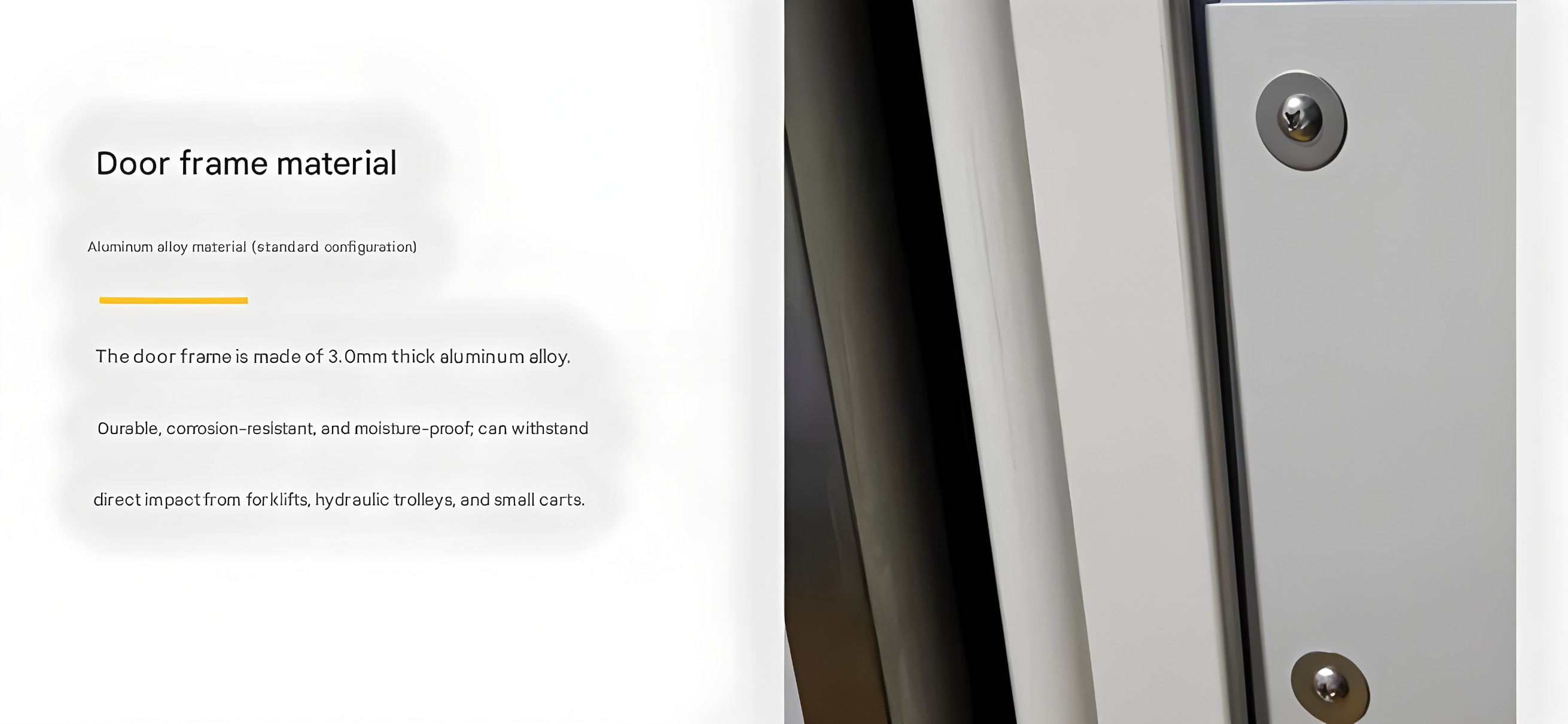

Made from high-toughness PVC base material with reinforced rib design, the door quickly rebounds and restores its shape after impacts from forklifts, carts, or other external forces. It resists deformation and damage, withstands frequent collisions and friction, extends service life, and reduces maintenance and replacement costs.

2. Flexible Material for Enhanced Safety

The door body has no rigid edges or corners, preventing hard injuries to personnel, vehicles, or goods during collisions. It eliminates the risks of bumps and scratches common with traditional rigid doors, making it ideal for high-traffic areas involving frequent personnel and vehicle passage.

3. Lightweight, Quiet, and Smooth Operation

Light overall weight allows easy opening without additional power—simply push gently with personnel or vehicles; it automatically closes afterward. Operation is smooth with minimal noise, causing no environmental disturbance.

4. Wear-Resistant and Weatherproof for Wide Applications

PVC material offers excellent resistance to abrasion, acids/alkalis, and moisture, suitable for diverse environments such as food processing workshops, cold chain warehouses, chemical plants, and logistics passages. It remains stable in high/low temperatures without becoming brittle or softening.

5. Superior Sealing for Dust and Pollution Control

Edge sealing design effectively blocks dust, odors, insects, and cold/hot air convection between indoor and outdoor areas when closed, maintaining internal cleanliness and temperature stability while contributing to energy savings.

6. Easy to Clean and Maintain, Hygienic Compliance

Smooth surface with no dead corners allows direct rinsing with water or wiping with cleaners. It resists bacterial growth and stain retention, meeting hygiene standards for industries like food processing and pharmaceutical cleanrooms.

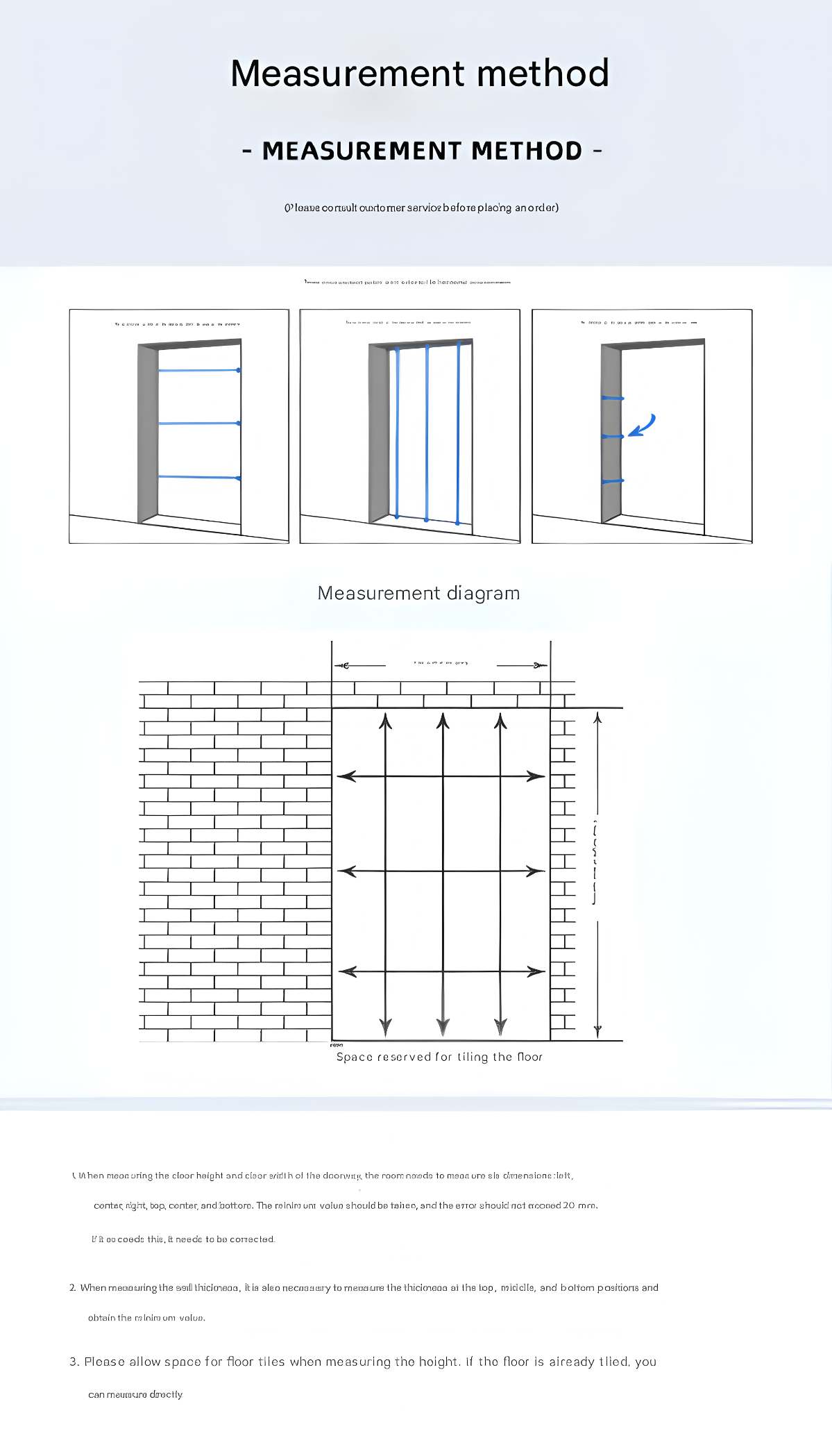

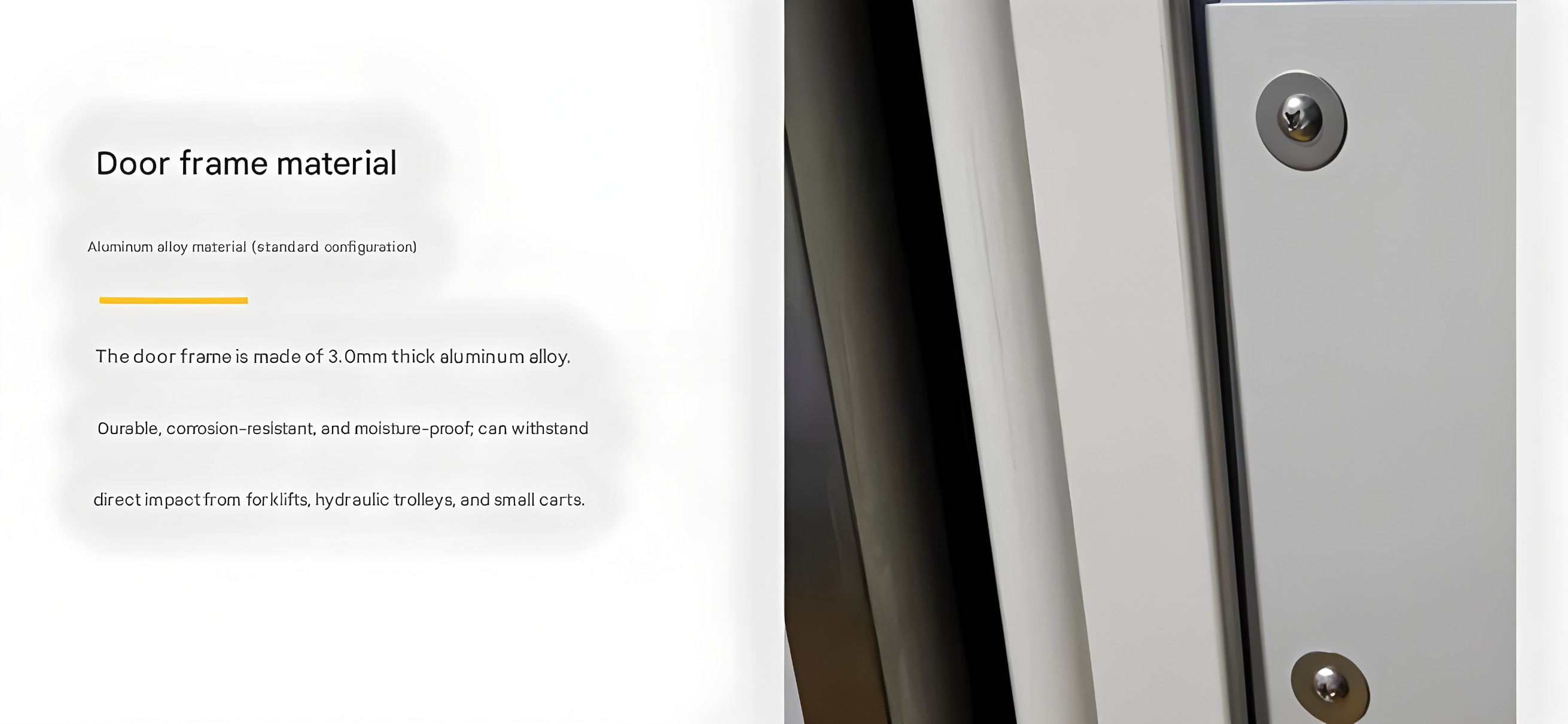

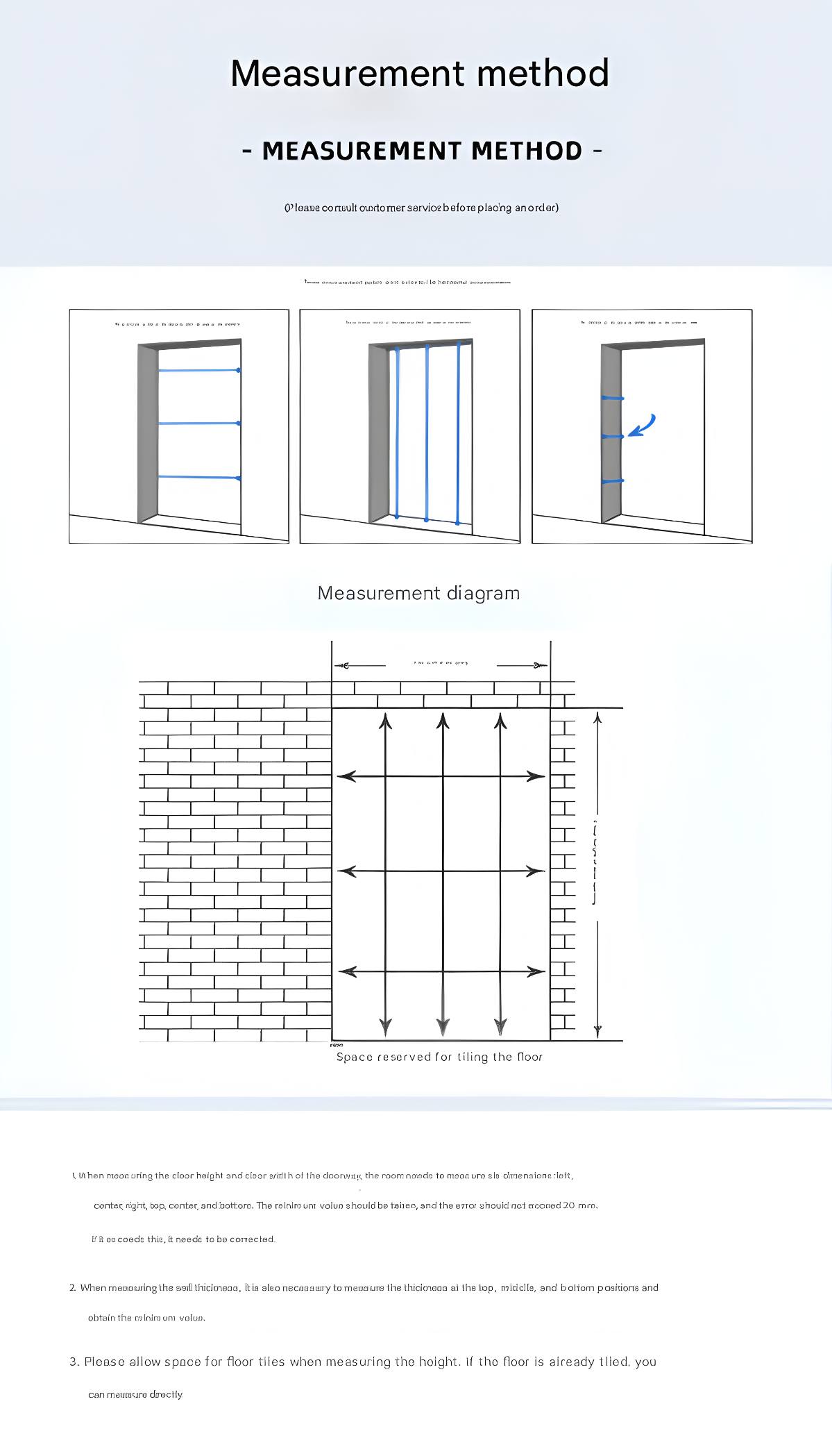

7. Easy Installation and High Adaptability

Simple structural design enables direct mounting on walls or door frames without complex civil modifications. Supports customization of sizes, colors, and thicknesses to fit various door opening specifications and meet individual needs.

8 .Cost-Effective with Outstanding Value

Compared to rigid industrial doors, it has lower purchase costs, simpler maintenance, and easier replacement, significantly reducing overall operational expenses for businesses.

Product Description

The flexible PVC anti-collision door is an ideal choice for high-frequency passage scenarios in industrial channels. Constructed with high-toughness PVC base material and reinforced rib structure, it offers excellent impact resistance and quick rebound, allowing rapid restoration after forklift collisions without deformation or damage.

The door body features no rigid edges, ensuring safety for personnel, vehicles, and goods during impacts. It combines lightweight design with quiet operation—opens easily upon touch and closes automatically, producing no noise disturbance.

Its sealing design effectively blocks dust, odors, and cold/hot air convection, helping maintain constant temperature and cleanliness in workshops. The smooth surface is easy to clean, resistant to acids/alkalis and moisture, making it suitable for diverse demanding environments such as food processing, cold chain storage, and pharmaceutical cleanrooms.

The product offers easy installation, customizable dimensions, low procurement and maintenance costs, and outstanding cost-effectiveness, providing enterprises with an efficient, safe, and economical passage solution.

Production Process

Exhibition & Package & Shipping

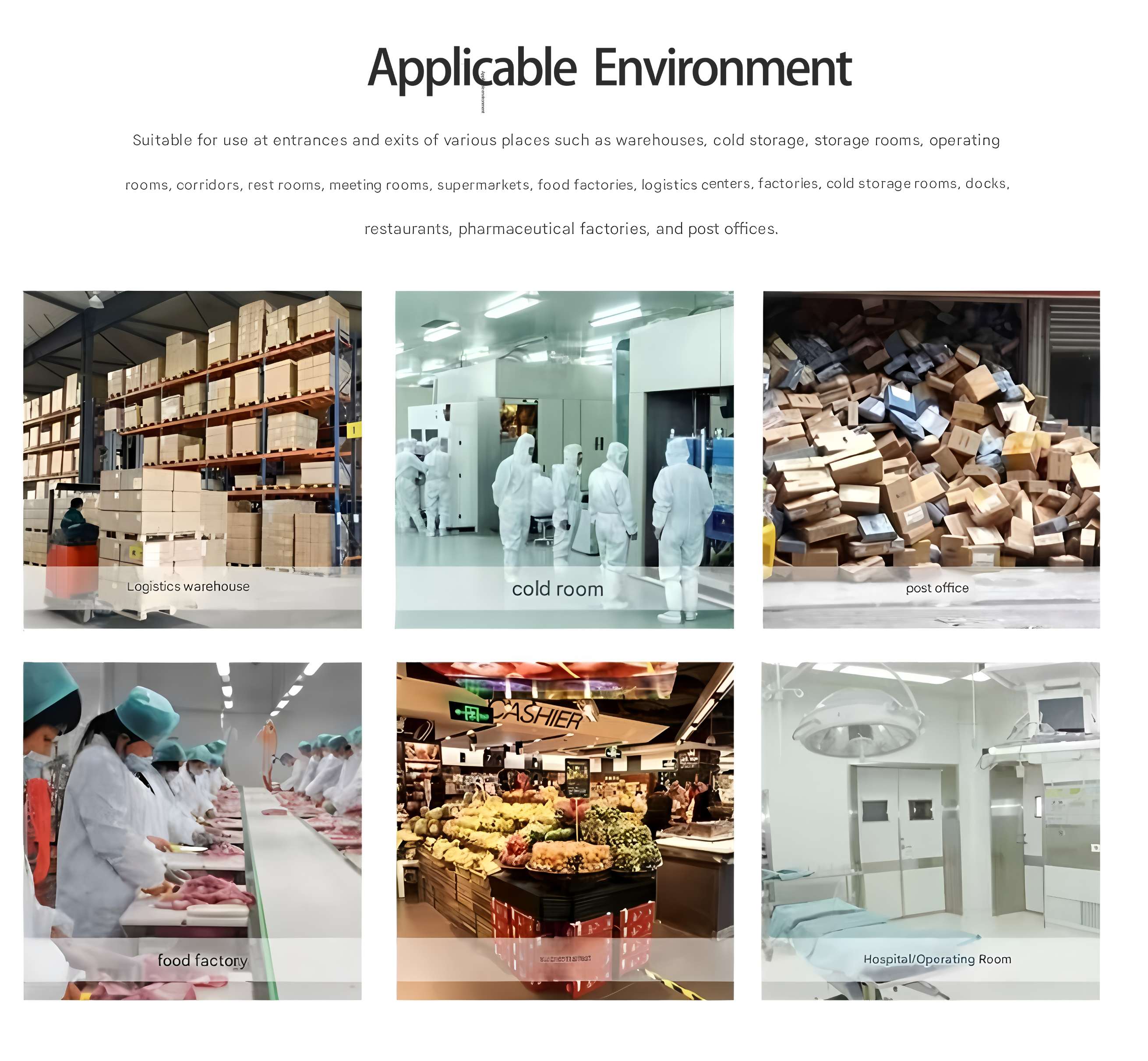

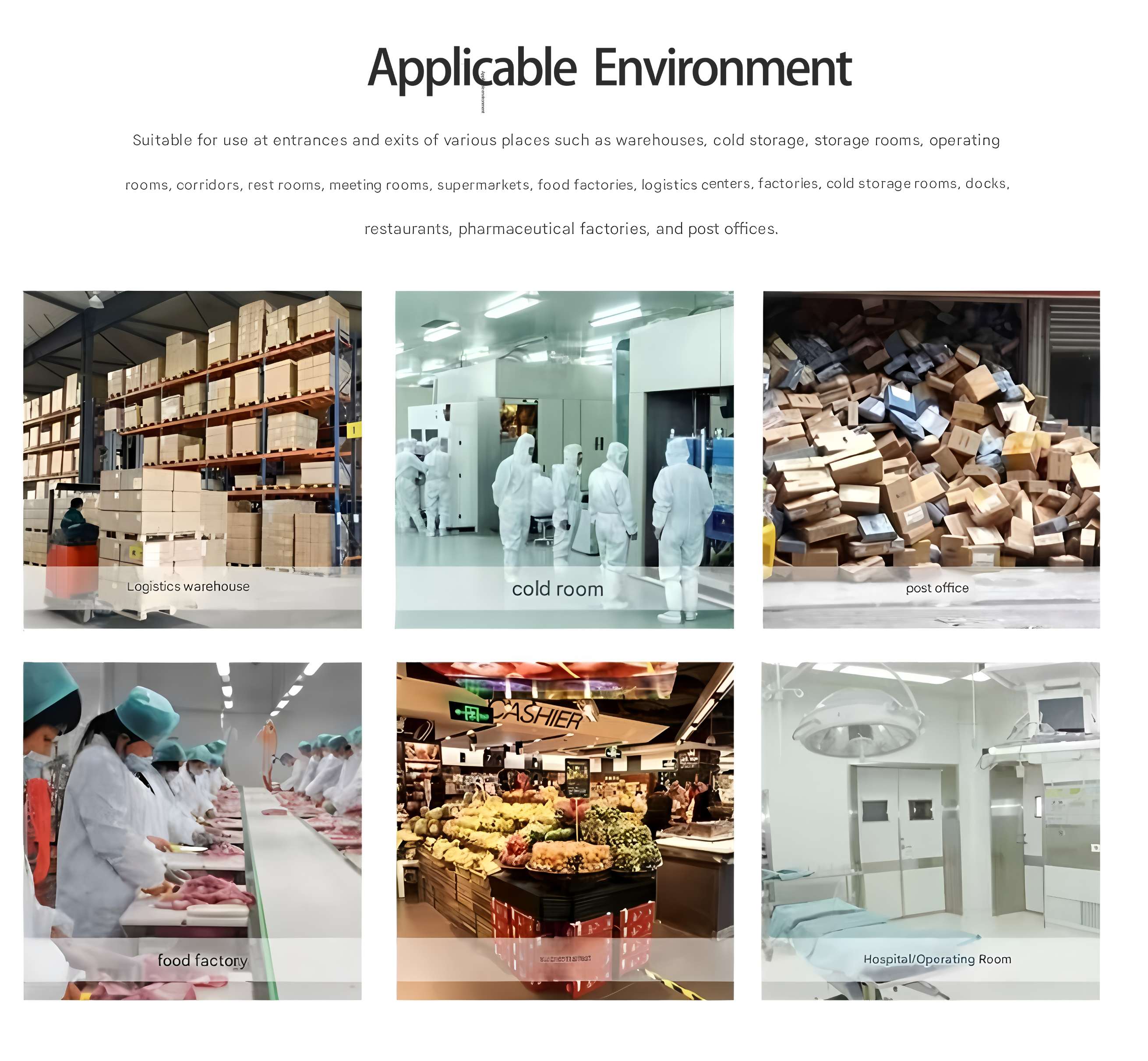

Product Applications

1. Food Processing Workshops

Suitable for passages between raw material areas, production zones, and packaging areas. Resistant to acids and alkalis, easy to clean, effectively blocks odors and dust between different zones, complies with food hygiene standards, and produces no debris upon collision, ensuring production safety.

2. Cold Chain Warehousing / Cold Storage

Resistant to high and low temperatures; the flexible material does not become brittle in low-temperature environments. When closed, it reduces cold/hot air convection, lowering energy consumption in cold storage. Quickly rebounds after frequent forklift impacts, maintaining efficient warehousing operations.

3. Pharmaceutical / Cleanroom Workshops

Meets clean environment requirements with superior sealing and dust prevention to block external contaminants. Smooth surface with no dead corners facilitates disinfection and sterilization, ideal for high-cleanliness scenarios such as pharmaceutical production and medical device assembly.

4. Logistics Sorting Centers / Warehouses

Ideal for sorting areas, loading/unloading zones, and goods circulation passages. Withstands high-frequency impacts from forklifts and hand carts, requires no electric power, opens upon touch, improves goods turnover efficiency, and reduces maintenance costs.

5. Chemical / Electronics Plants

Highly corrosion-resistant, withstands erosion from acid/alkali gases and humid environments, protecting internal equipment and materials. Eliminates spark risks from collisions associated with rigid doors, enhancing safety.

6. Supermarkets / Fresh Produce Distribution Centers

Used for separation between fresh refrigerated areas and sales passages, minimizing cold air loss. Lightweight and quiet operation does not disturb customer shopping experience. Easily restores shape after collisions, suitable for mixed personnel and vehicle traffic scenarios.

After-sales Service

1. Free Installation, Commissioning, and Training

We arrange a professional technical team to provide on-site free installation and commissioning of the door body and control system, ensuring operating parameters meet usage standards. Simultaneously, we offer one-on-one operational training for logistics and equipment management teams, covering daily opening/closing, linkage settings, basic troubleshooting, and more. Operation manuals and maintenance guides will be provided.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, while the entire unit has a 1-year warranty. During the warranty period, non-human-induced faults qualify for free repair and parts replacement.

3. Regular Inspections and Preventive Maintenance

During the warranty period, technicians will conduct on-site inspections every 6 months, checking door sealing performance, sensor sensitivity, motor operation status, etc. Aging wearable parts (such as brush seals) will be replaced promptly to eliminate potential faults. After the warranty expires, an annual maintenance contract can be signed for discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

Ensuring timely availability of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

We provide lifetime free technical consultation to resolve various issues during use. For future upgrades to door linkage functions (e.g., integration with new access control or fire systems), cost-price technical upgrade services are available, tailored to hospital intelligent transformation needs.

FAQS

1.Q: How much impact force can the flexible PVC anti-collision door withstand?

A: Constructed with high-toughness PVC base material and reinforced rib composite structure, it can withstand high-frequency impacts from conventional industrial forklifts (2-3 tons). It quickly rebounds and restores shape after collision, resisting deformation or damage. Specific impact resistance can be customized based on door opening size and door thickness to meet varying scenario requirements.

2.Q: Is this anti-collision door suitable for low-temperature environments?

A: Yes, it is fully suitable. The PVC material undergoes low-temperature modification for stable performance in -30°C to 60°C ranges, without becoming brittle, cracking, or softening. It is ideal for cold storage, cold chain warehousing, and similar low-temperature settings, while reducing cold/hot air convection for energy savings.

3.Q: Does installation require a professional team? Can I install it myself?

A: The installation process is simple and does not require a professional team. The product includes complete accessories and instructions. With its straightforward design, it can be directly fixed to walls or door frames without complex civil modifications. Typically, 2-3 people can complete the installation, significantly saving time and costs.

4.Q: How to clean and maintain it daily? Does it require special care?

A: No special care is needed; daily cleaning is extremely convenient. The smooth surface with no dead corners can be rinsed directly with water, sprayed with a high-pressure water gun, or wiped with neutral detergent. It resists bacterial growth and stain retention. Regularly check hinges and seals for integrity and tighten if loose.

5.Q: Can it be customized in different sizes and colors?

A: Full customization is supported. Door body dimensions can be tailored to actual opening width and height, with thickness options from 3-8mm. Colors include standard industrial shades like white, blue, yellow, or custom options based on workshop zoning needs for personalized and scenario-specific adaptation.

6.Q: Does the flexible PVC anti-collision door meet hygiene standards for food and pharmaceutical industries?

A: Yes, it complies. Made from food-grade PVC material with no odor or harmful substance release, the smooth surface is easy to clean and resists bacteria. It is suitable for high-hygiene environments like food processing workshops and pharmaceutical cleanrooms, fully meeting relevant industry standards.

7.Q: Without electric drive, is closing smooth? Will it fail to close?

A: Closing is smooth with no risk of failure. The product relies on its own counterweight and hinge spring force for automatic closing. Optimized design ensures uniform closing speed—opens upon touch and quickly resets after passage—without needing power, ideal for powerless or energy-saving scenarios.

8.Q: What are the advantages compared to traditional rigid industrial doors?

A: Core advantages lie in safety, economy, and convenience: ① Flexible material with no rigid edges prevents injury on collision; ② High impact resistance and easy rebound for low maintenance costs; ③ Lightweight and quiet operation without disturbing production; ④ Flexible installation and customization with lower purchase costs, offering far superior overall value.

Procurement advantages

1. Low Procurement Costs

Compared to traditional rigid industrial doors (such as metal or glass doors), flexible PVC material offers simpler raw material costs and production processes, resulting in significantly lower initial purchase investment.

2. Reduced Operation and Maintenance Costs

Highly resistant to frequent impacts with minimal risk of deformation or damage, greatly lowering repair and replacement frequency. Daily cleaning and maintenance are simple, requiring no professional personnel or special consumables, ensuring controllable long-term operating costs.

3. Flexible Customization

Supports full-dimensional customization of door opening size, thickness, and color, adapting to specific requirements in food processing workshops, cold storage, pharmaceutical cleanrooms, logistics warehouses, and other scenarios.

4. High Environmental Resistance

Resistant to acids/alkalis, moisture, and stable in high/low temperatures, eliminating the need for additional specialized doors in different environments and reducing procurement complexity.

5. Low Installation Barrier

Simple structural design with complete installation accessories and instructions, allowing in-house personnel to complete installation without professional construction teams, saving on service fees.

6. No Civil Engineering Modifications Required

Can be directly installed on existing walls or door frames, avoiding complex demolition or renovation work, shortening installation time without disrupting normal production operations.

7. Comprehensive Safety Protection

Flexible material with no rigid edges protects personnel, vehicles, and goods during collisions, reducing workplace accident rates and minimizing compensation and downtime losses.

8. Compliance with Industry Standards

Made from food-grade PVC material, easy to clean with no bacterial growth, fully meeting hygiene requirements in food and pharmaceutical industries and avoiding penalties due to non-compliance.

9. Effective Sealing and Insulation

When closed, effectively blocks cold/hot air convection, dust, and odors, helping maintain constant temperature and cleanliness in workshops while reducing energy consumption for air conditioning and refrigeration equipment over the long term.

10. No Electricity Dependency

Opens upon touch and closes automatically without requiring motors or other power equipment, saving on electricity usage and equipment maintenance costs.