Product Feature

I. Superior Fireproofing and Thermal Insulation Performance

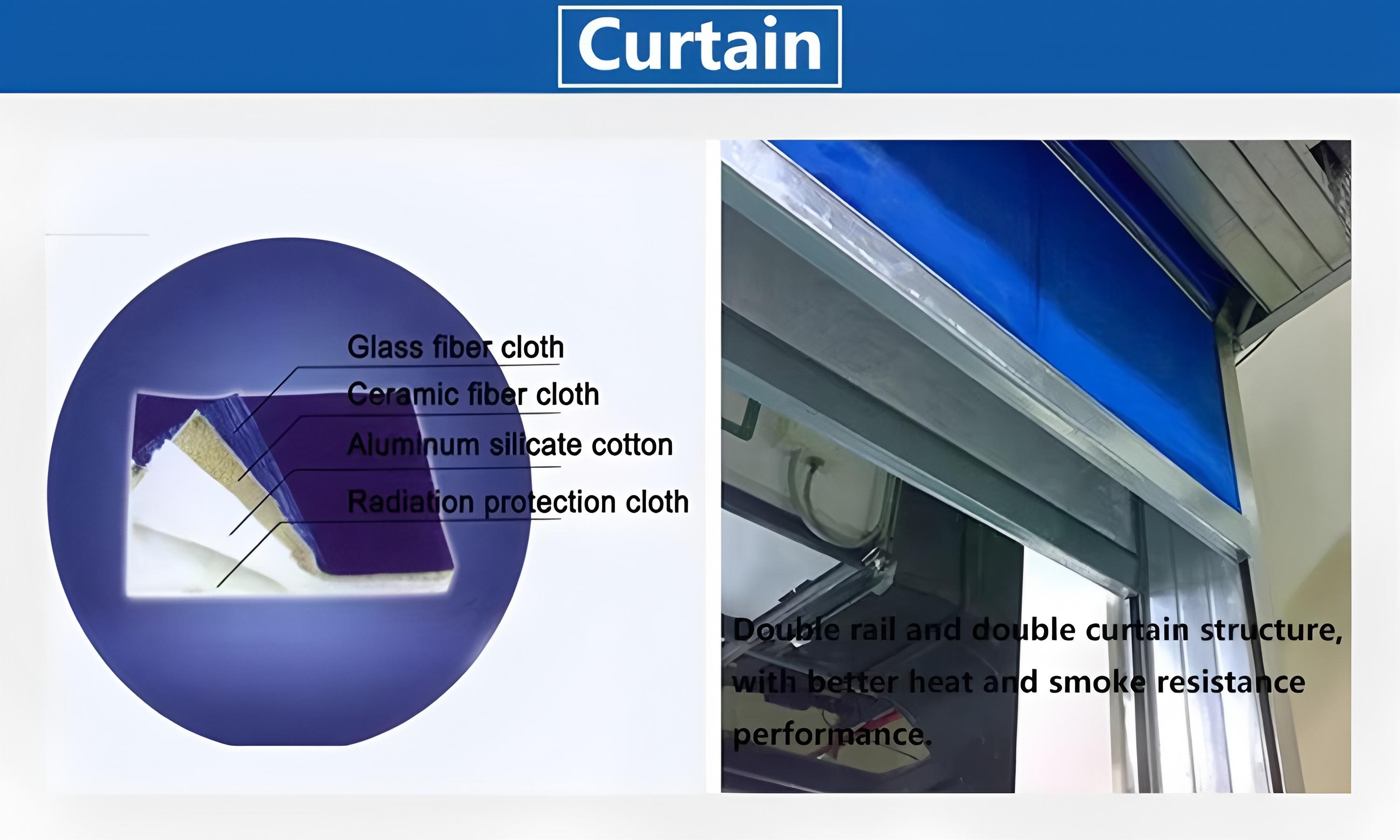

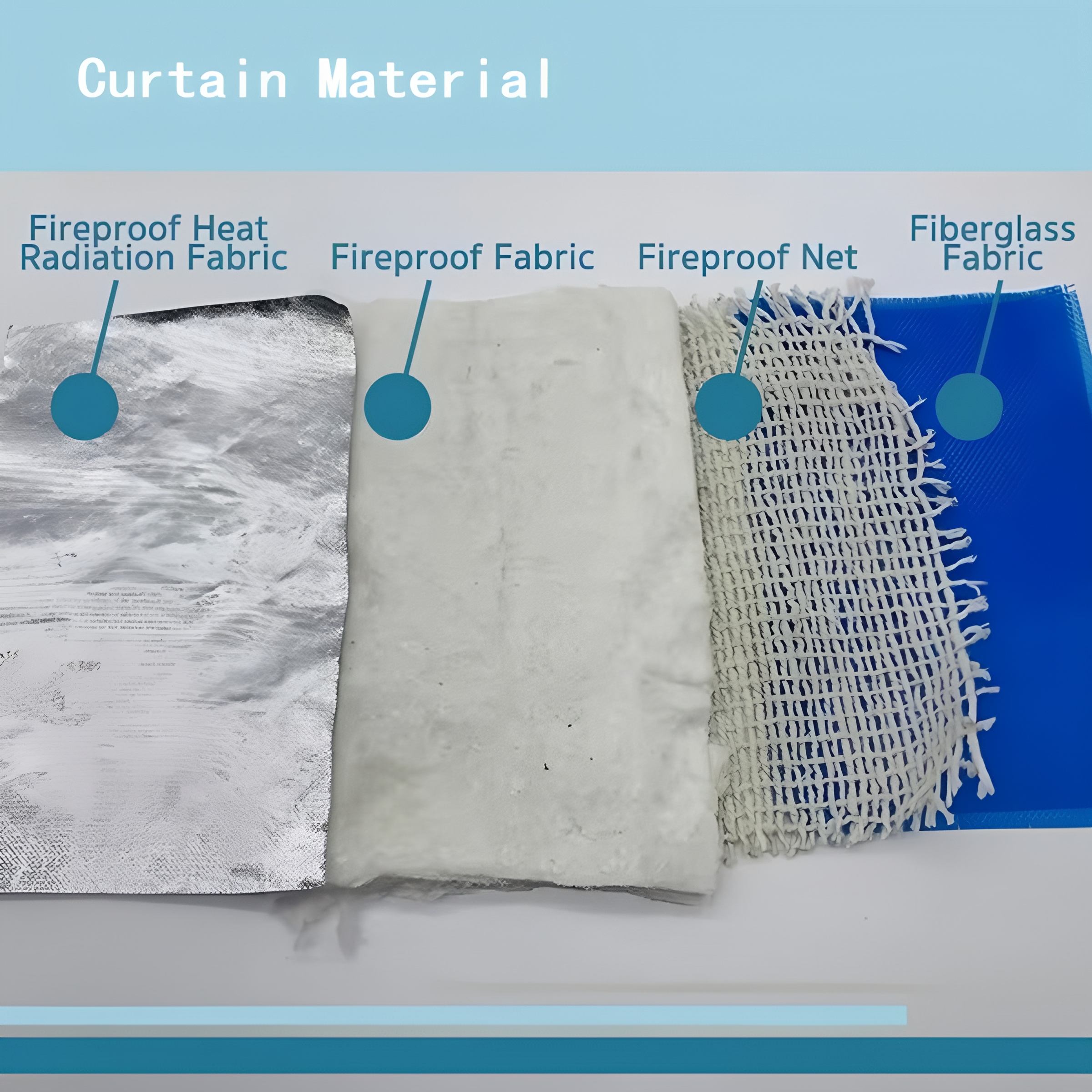

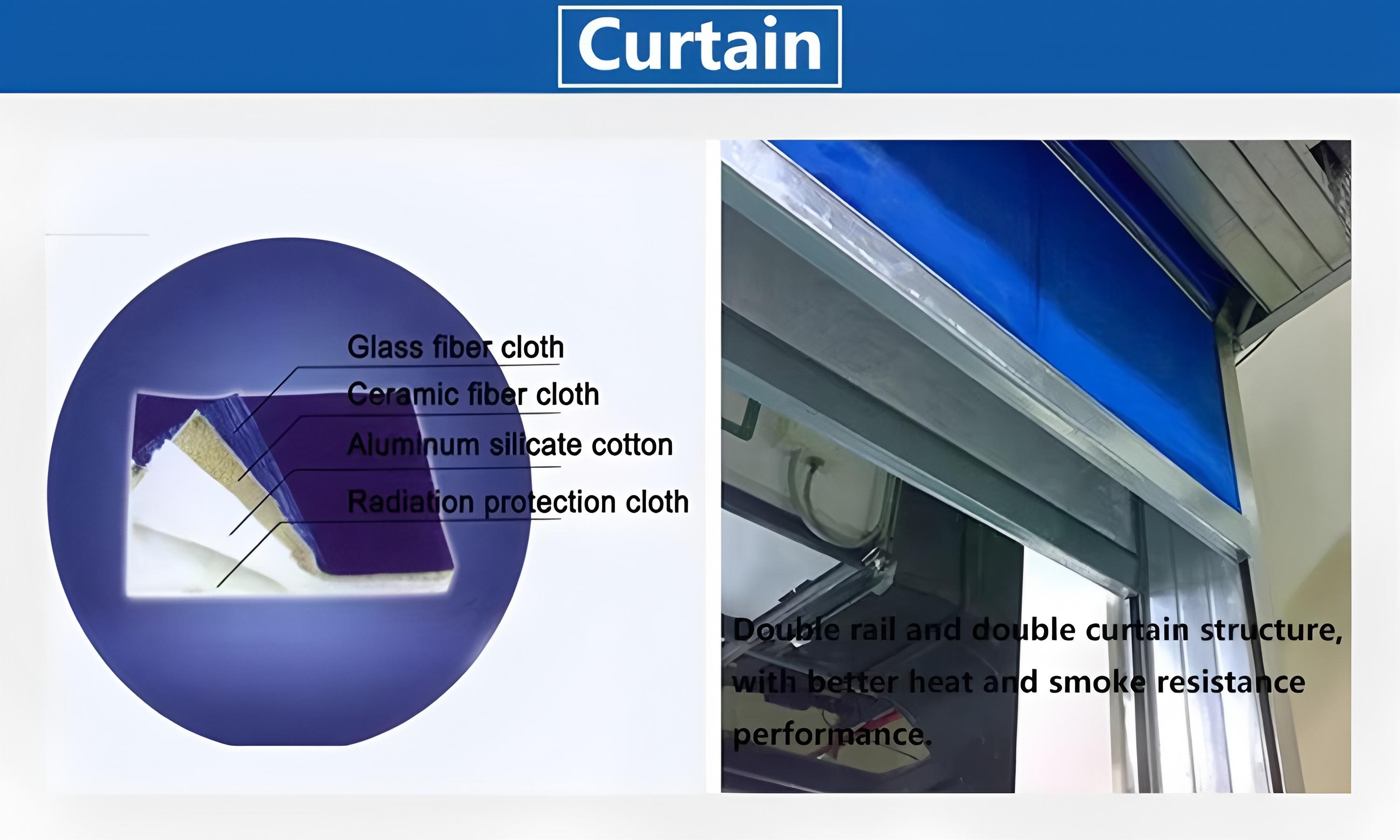

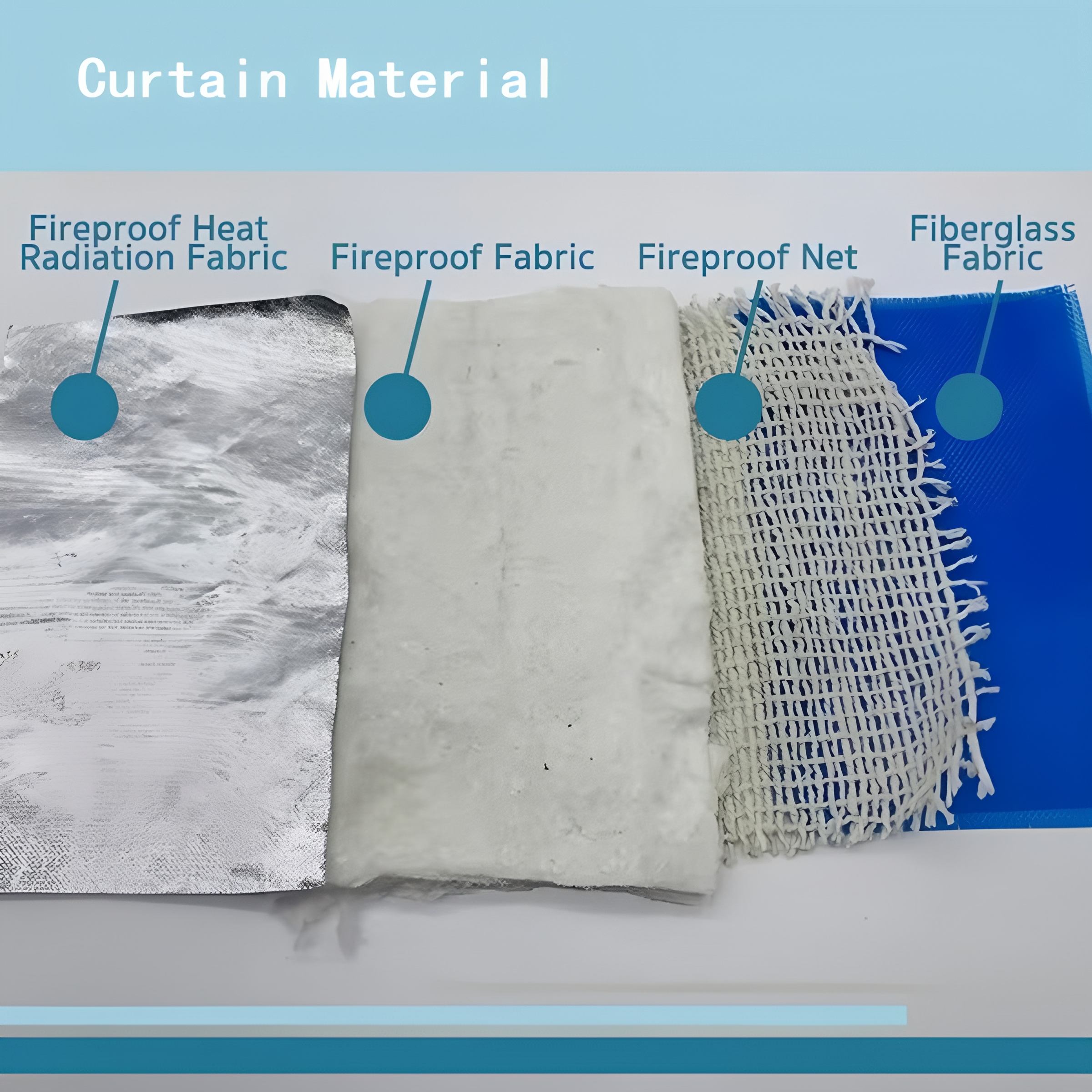

Utilizing high-performance inorganic fiber cloth as the core fire-resistant substrate, combined with special fireproof coatings and high-temperature-resistant sealing materials, it effectively blocks flame spread and high-temperature conduction. Certified by authoritative testing, the fire resistance limit reaches 4 hours or more, providing valuable time for personnel evacuation and property protection during a fire. Fully complies with national standards for fire roller shutters.

II. Lightweight, Environmentally Friendly, and Easy to Install

Compared to traditional steel fire roller shutters, the inorganic cloth material significantly reduces weight—to only 1/3–1/2 of steel products—greatly lowering structural load-bearing pressure and requirements on installation walls. The product uses formaldehyde-free and non-toxic volatile materials, aligning with green building principles. Its modular design simplifies transportation and installation, adapts to various door opening sizes, shortens construction periods, and reduces labor costs.

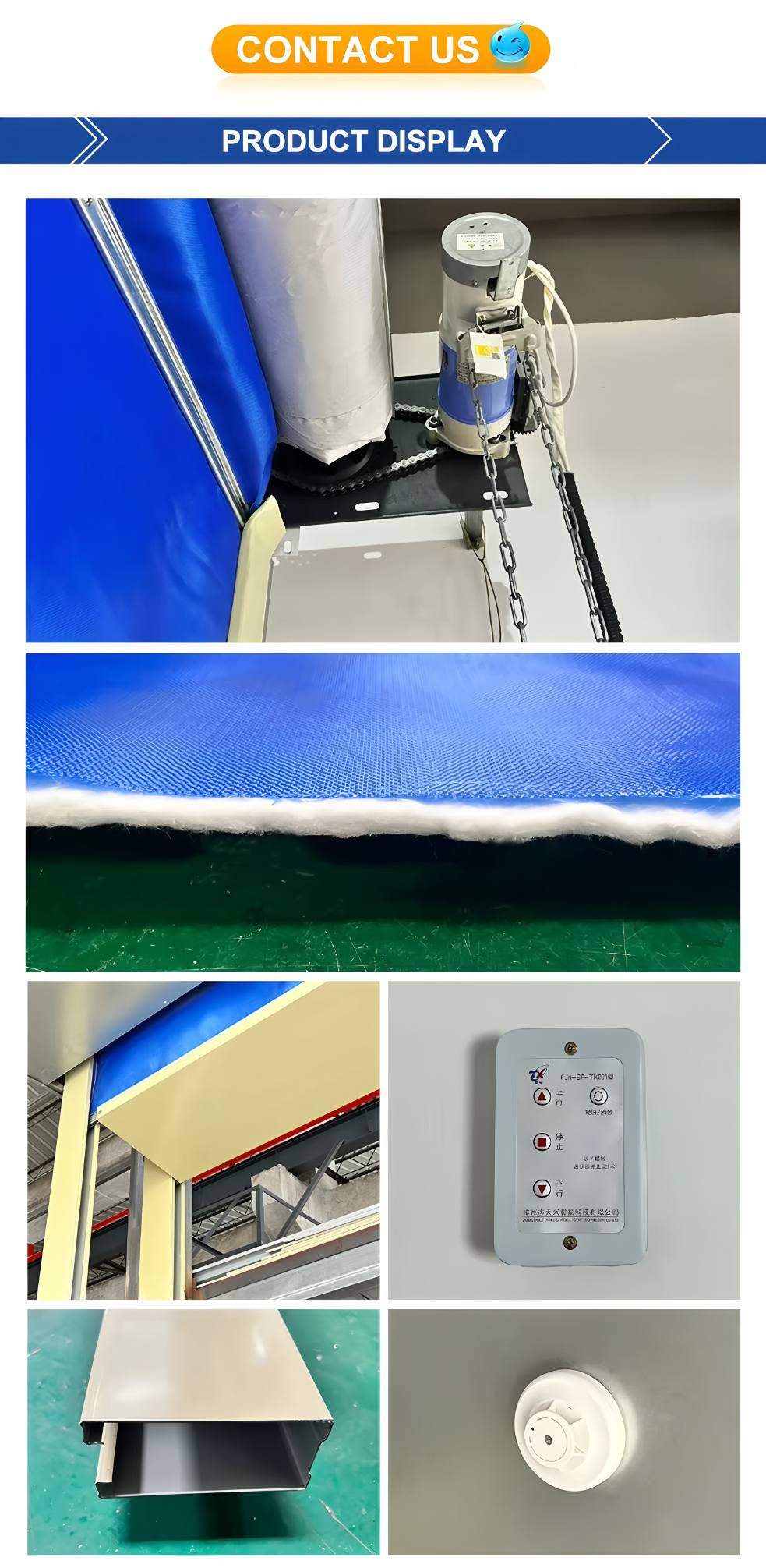

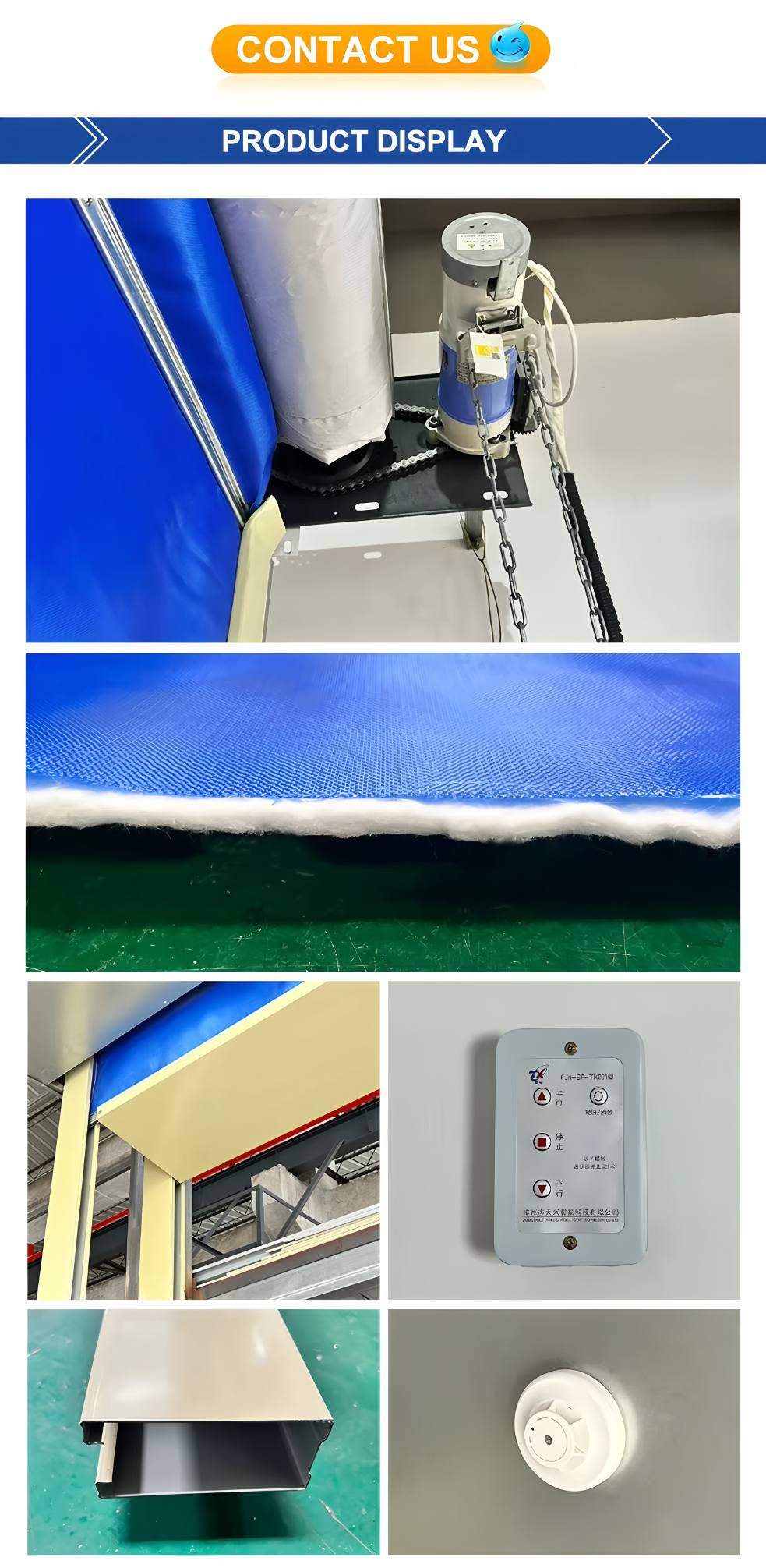

III. Smooth Operation with Low Noise

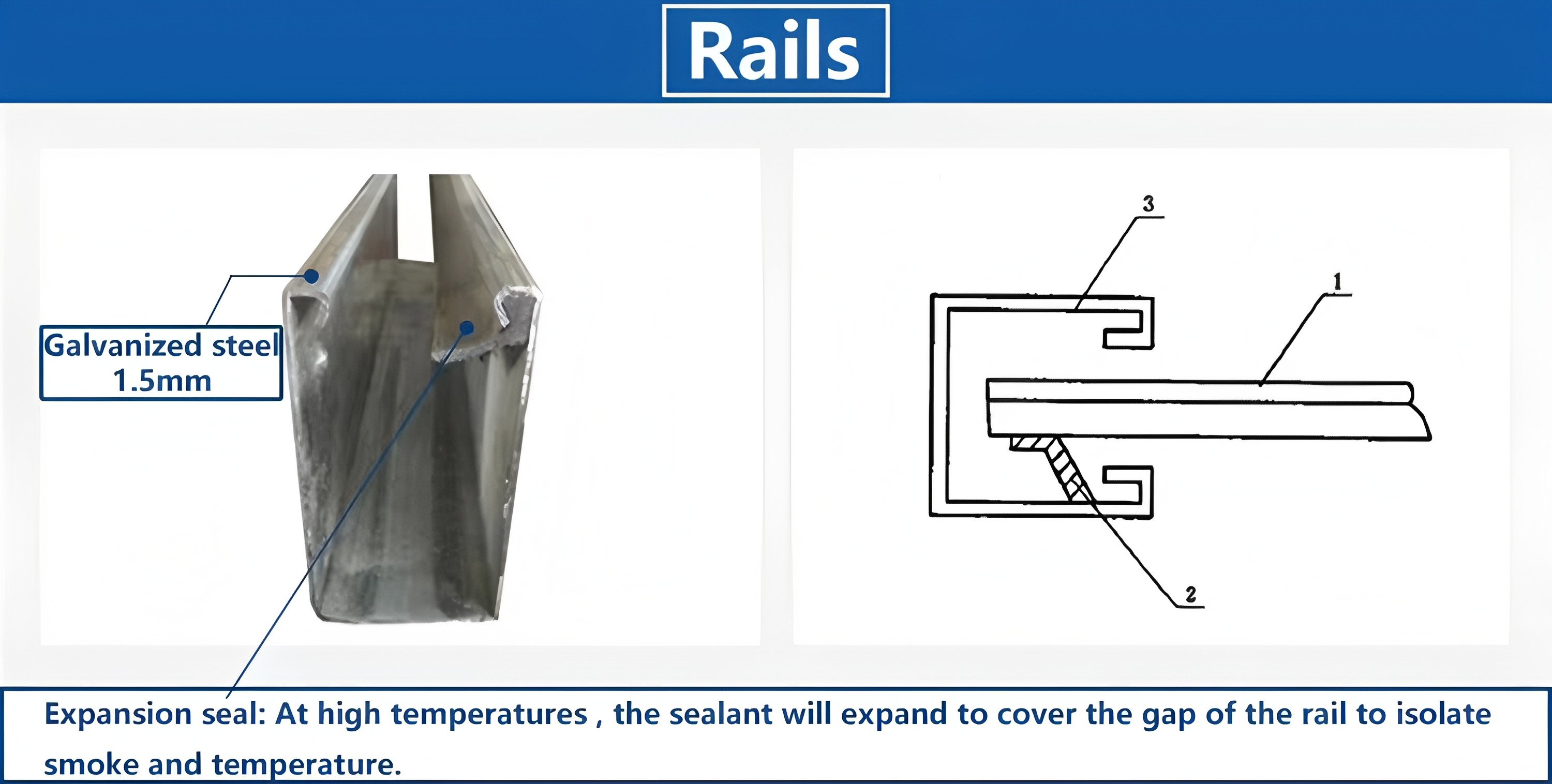

Equipped with a high-precision transmission system and silent guide mechanism, the door opens and closes smoothly without noticeable jamming. Operating noise is below 60 decibels—far superior to traditional roller shutters—making it suitable for noise-sensitive locations such as shopping malls, hospitals, office buildings, and underground parking garages, ensuring fire protection without compromising daily environmental comfort.

IV. Strong Corrosion Resistance and Weather Durability

The inorganic cloth substrate offers excellent resistance to corrosion and aging, effectively withstanding humid, acidic, or alkaline environments with minimal maintenance required. The outer protective fabric also provides superior resistance to sunlight and rain, maintaining stable performance over the long term in both indoor and semi-outdoor installations, with a service life exceeding 10 years.

V. Flexible Adaptation to Diverse Scenarios

Supports multiple control methods, including manual, electric, and linked control (integration with fire safety systems), meeting various fire management needs. The product can be customized for vertical lifting, lateral sliding, or other opening modes to accommodate large spans and high door openings. Additionally, the inorganic cloth can incorporate transparent vision windows, balancing fire protection with natural lighting requirements—ideal for commercial displays, passage partitions, and other diverse applications.

Product Description

The inorganic cloth fire roller shutter is a fire safety product that combines robust protection with practical convenience.

Its core utilizes high-performance inorganic fiber cloth substrate, paired with fireproof coatings and sealing structures, achieving a fire resistance limit of over 4 hours. It effectively blocks flames and high temperatures, providing critical time for emergency response during fires.

Compared to traditional steel roller shutters, its lightweight design significantly reduces structural load-bearing pressure, enabling easier installation and shorter construction periods.

Equipped with a silent transmission system, it operates smoothly with low noise, making it ideal for noise-sensitive environments such as shopping malls, hospitals, and office buildings.

The product offers strong corrosion resistance and weather durability, suitable for both indoor and outdoor use with minimal maintenance costs.

It supports manual, electric, and fire-linked control modes, with customizable opening methods and sizes to flexibly meet diverse architectural needs. It is an ideal choice for green buildings and fire safety compliance.

Production Process

Exhibition & Package & Shipping

Product Applications

I. Commercial Complexes and Public Venues

Suitable for fire compartment partitioning in commercial complexes such as shopping malls, supermarkets, and shopping centers—e.g., between individual stores or separating atria from retail areas. Its smooth operation and low noise characteristics avoid disrupting the customer shopping experience. It also supports customization for large-span sizes to accommodate the open layouts of commercial spaces. Additionally, it can be widely applied in evacuation passages and equipment room entrances in public venues like libraries, sports arenas, and exhibition centers, achieving efficient fire separation without occupying excessive space.

II. Medical and Educational Facilities

Hospitals’ inpatient buildings, outpatient departments, and pharmacies have high requirements for environmental quietness and hygiene. The inorganic cloth fire roller shutter’s silent operation and environmentally friendly, odor-free features make it a perfect fit. In schools, kindergartens, teaching buildings, laboratories, and dormitories, it ensures the safety of teachers and students. Its excellent fireproofing and thermal insulation performance buys critical time for personnel evacuation during fires and effectively blocks flame spread.

III. Underground Structures and Transportation Hubs

Underground parking garages, underground shopping malls, and metro stations feature enclosed spaces, poor ventilation, and often humid conditions. The inorganic cloth fire roller shutter’s strong corrosion resistance and weather durability adapt well to damp underground environments without easily rusting or deteriorating. It can also link with fire safety systems to automatically close during fires, creating fire compartments and preventing smoke spread. Furthermore, in transportation hubs such as airport terminals and high-speed rail stations—in waiting halls and baggage sorting areas—it enables effective fire separation and safety management.

IV. Industrial and Warehousing Facilities

Suitable for boundaries between production areas and raw material/finished goods warehouses in factories, as well as entrances to clean workshops and hazardous material storage areas in industries like chemicals, electronics, and food processing. Its fireproof performance effectively contains potential fire risks during production or storage. The lightweight material imposes minimal load on industrial steel structures. Models with customizable transparent vision windows also meet requirements for natural lighting and internal visibility in workshops.

V. Residential Building Applications

In high-rise residences and apartment buildings, inorganic cloth fire roller shutters can be installed in fire elevator lobbies, stairwell entrances, and equipment shaft areas as essential fire separation facilities to ensure building fire safety. Their easy installation and space-saving design suit the compact layouts of residential buildings without affecting daily resident access or living space.

After-sales Service

1. Free Installation, Commissioning, and Training

A professional technical team provides on-site free installation and commissioning of the door body and control system, ensuring that operating parameters meet usage standards. In addition, one-on-one operational training is provided to logistics and equipment management teams, covering daily opening/closing, linkage settings, basic troubleshooting, and more, with operation manuals and maintenance guidelines distributed.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, and the complete unit with a 1-year warranty. During the warranty period, non-human-induced faults are repaired or parts replaced free of charge.

3. Regular Inspections and Preventive Maintenance

Within the warranty period, a technician conducts one on-site inspection every 6 months to check door sealing performance, sensor sensitivity, motor operation status, etc., promptly replacing aging wearable parts (such as brush seals) and addressing potential issues. After the warranty expires, an annual maintenance agreement can be signed to receive discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

Ensures timely availability of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

Offers lifetime free technical consultation to resolve various issues encountered during use. For future upgrades to door linkage functions (e.g., integration with new access control or fire safety systems), cost-price technical upgrade services are available, suitable for intelligent transformation needs in hospitals and similar facilities.

FAQS

1. Q: What is the core difference between fire-rated rolling shutter doors and ordinary rolling shutter doors?

A: The core difference lies in fire resistance performance and certification standards. Fire-rated rolling shutter doors are made of fire-retardant materials (such as fireproof fabric, aluminum silicate fiber composite panels, etc.), must pass national fire product certification, and have fireproof, heat-insulating, and smoke-isolating functions. In the event of a fire, they can descend according to a preset program to block the spread of fire. Ordinary rolling shutter doors only focus on anti-theft and sunshade functions, lack fire resistance performance, do not have fire protection certification, and cannot be used for fire compartment separation.

2. Q: How are the fire ratings of fire-rated rolling shutter doors classified?

A: According to the national standard "Fire Shutter Doors" (GB 14102-2005), fire-rated rolling shutter doors are mainly divided into Special Grade, Grade A, and Grade B:

- Special Grade fire-rated rolling shutter:** Fire endurance limit ≥4.0h.

- Grade A fire-rated rolling shutter:** Fire endurance limit ≥3.0h, suitable for high-risk areas such as fire walls in fire compartments and flammable/explosive sites.

- Grade B fire-rated rolling shutter:** Fire endurance limit ≥1.5h, suitable for areas with slightly lower fire performance requirements, such as evacuation passages and elevator lobbies.

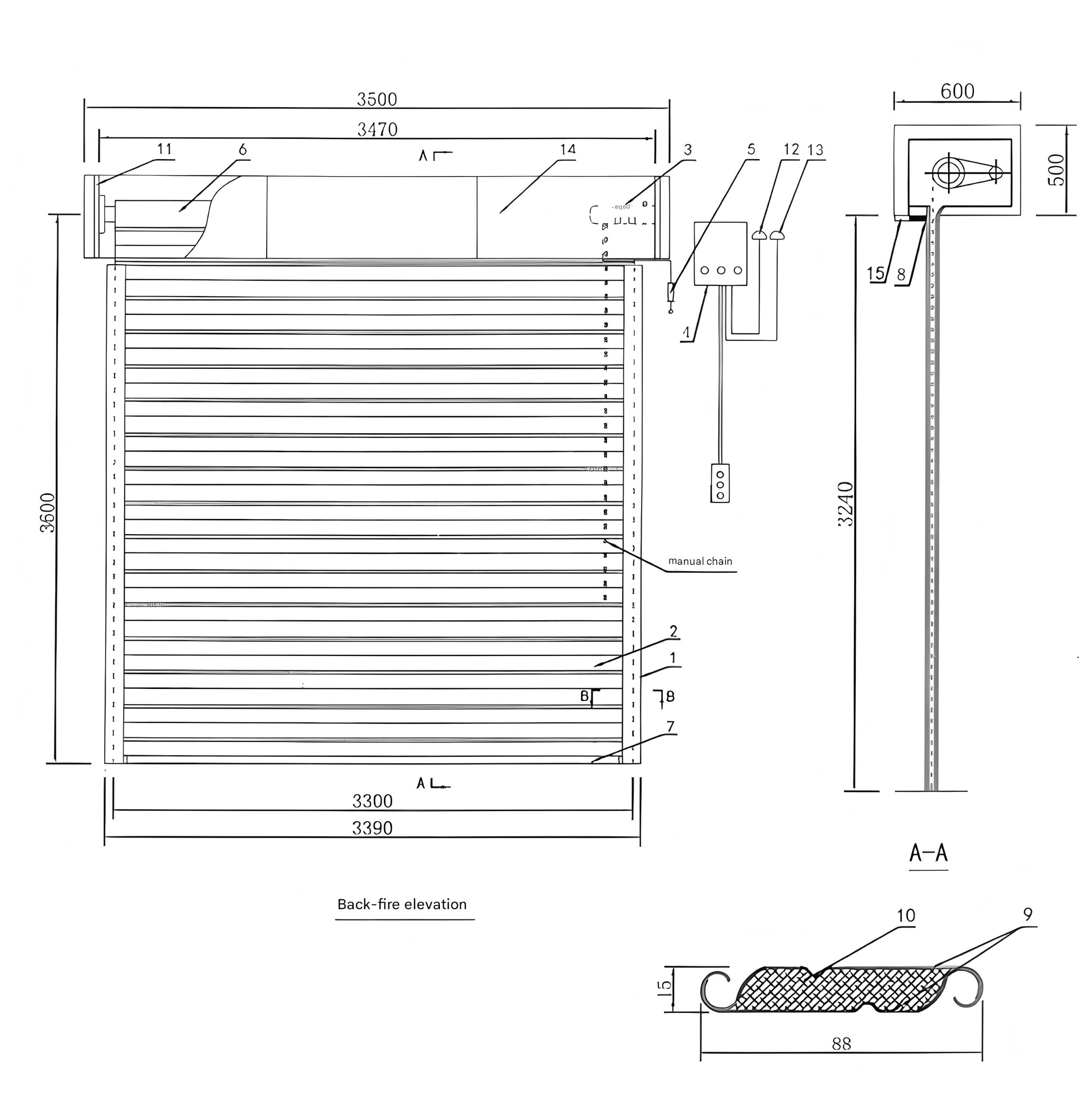

3. Q: Do fire-rated rolling shutter doors close automatically or manually in the event of a fire?

A: They feature both automatic and manual control functions.

- Automatic control: Linked with the building's fire automatic alarm system. When detectors sense a fire, the shutter descends in two steps (first step: descends to 1.8m above the ground and pauses to facilitate personnel evacuation; after a delay, descends fully to the ground to completely seal the fire compartment).

- Manual control:Equipped with on-site manual control buttons for manually operating the shutter's ascent, descent, and stop; also features a manual pull chain for opening/closing in case of power outage.

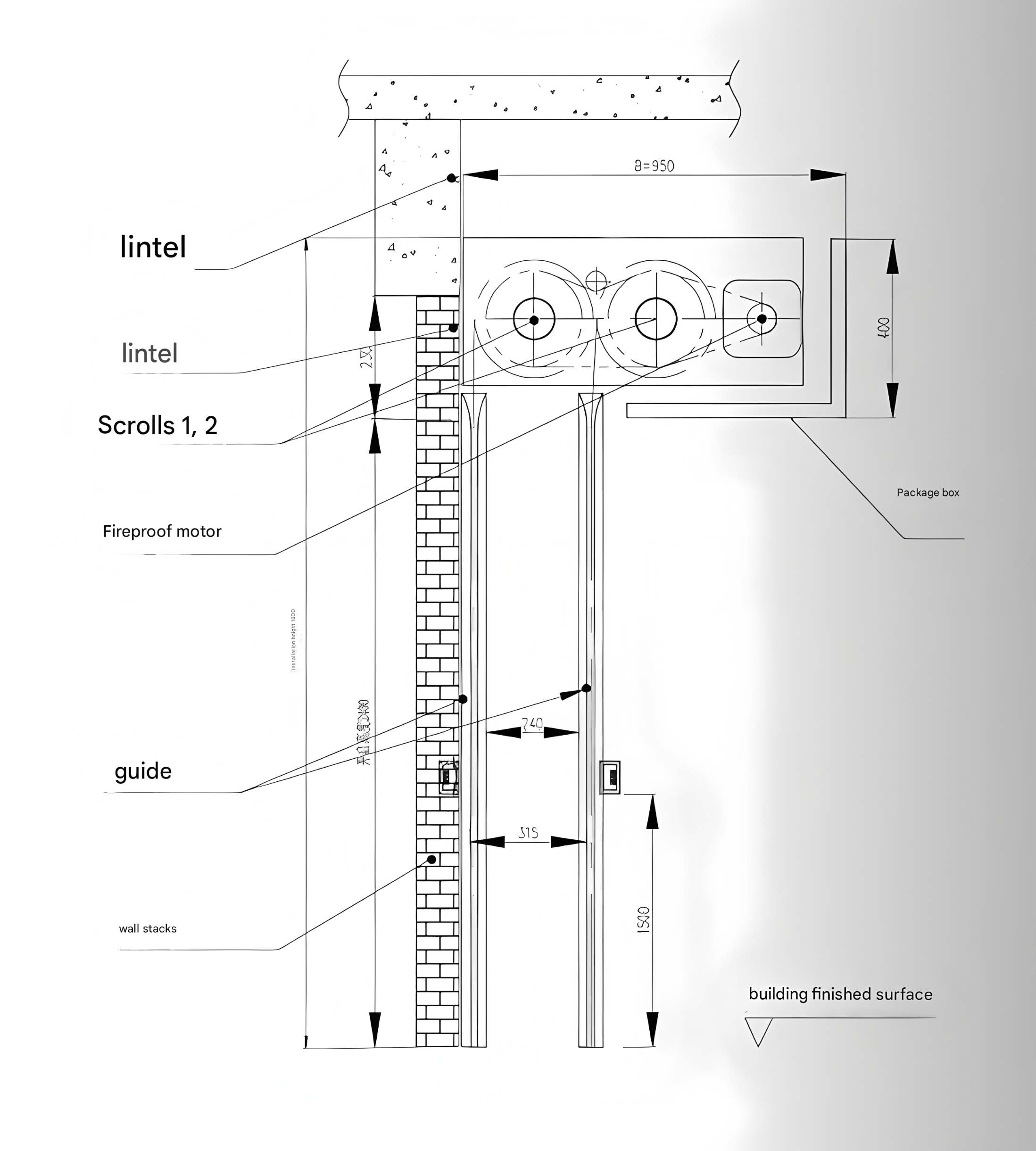

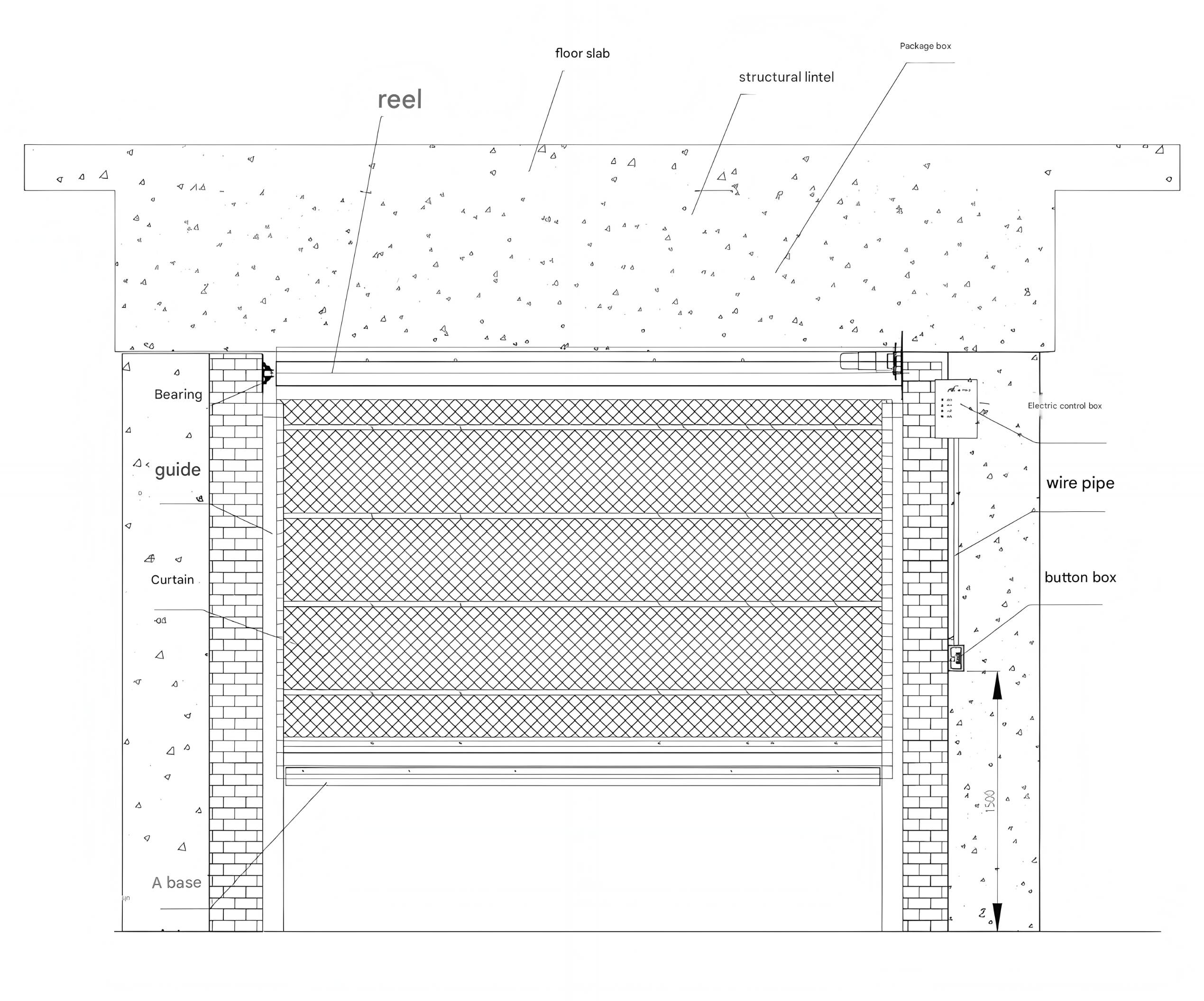

4. Q: What are the requirements for the door opening when installing a fire-rated rolling shutter door?

A: There are three main requirements:

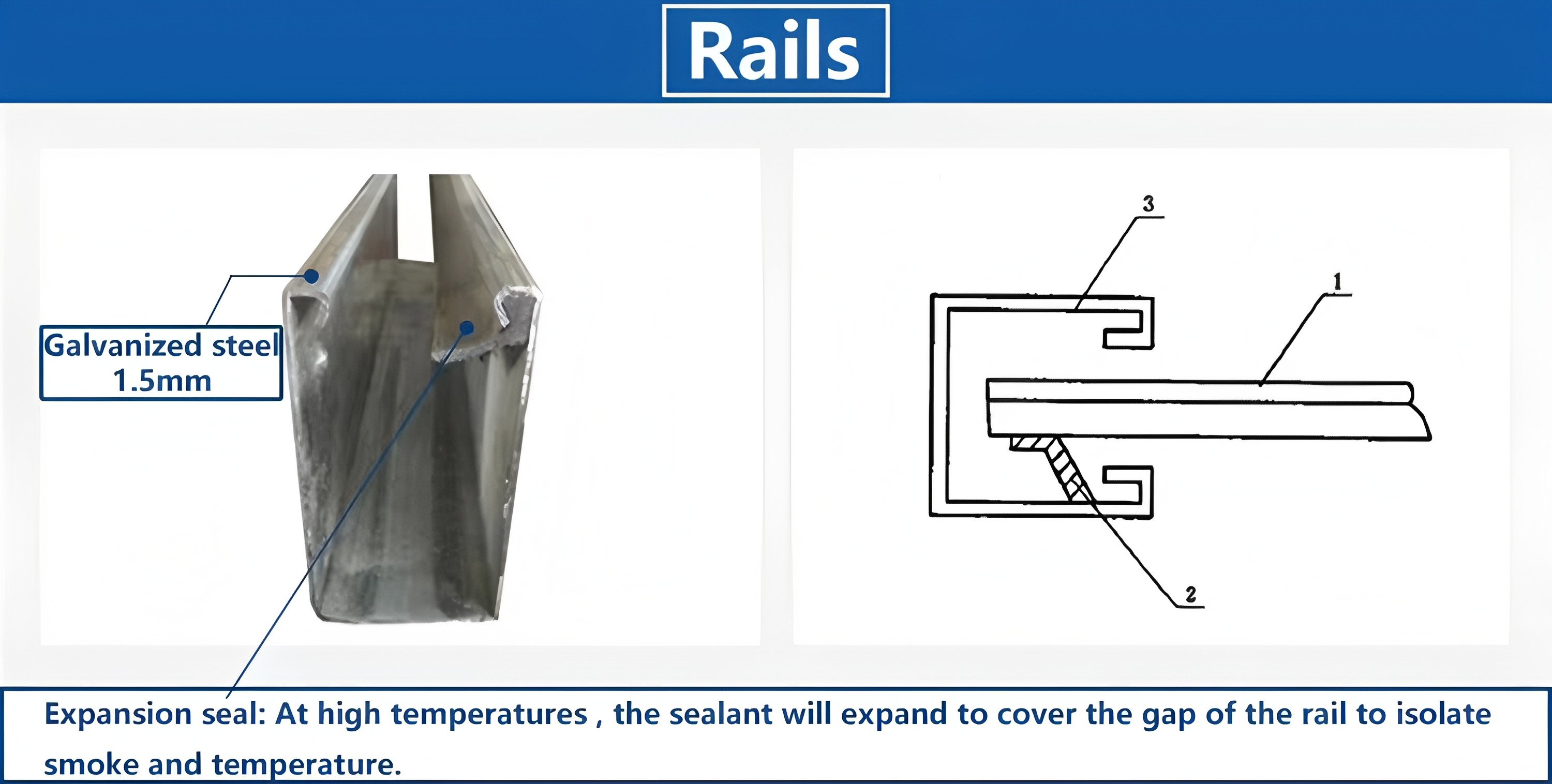

- Door opening size: Determined based on the shutter model, with ≥150mm installation space reserved on both sides and ≥300mm space above for the reel installation.

- Door opening verticality: Left-right vertical deviation ≤5mm to avoid jamming during operation.

- Installation environment: A sturdy steel structural bracket must be pre-installed above the door opening to fix the reel and motor, ensuring sufficient load-bearing capacity.

5. Q: What should be noted in the daily use of fire-rated rolling shutter doors?

A: Daily use should follow the following specifications:

- Strictly prohibit stacking debris under the shutter to ensure the ascent/descent channel is unobstructed.

- Regularly test the automatic control function (monthly linkage test once), checking if the motor, control box, and limit switches are normal.

- Avoid frequent manual forced opening/closing to prevent deformation of the shutter body guide rails or motor damage.

- If there are stains on the shutter surface, wipe with a neutral cleaner and avoid using strongly corrosive chemical agents.

6. Q: Can fire-rated rolling shutter doors still be used after a power outage?

A: Yes. Fire-rated rolling shutter doors are equipped with a backup power supply (which can maintain control box and motor operation for a period after power outage) or a manual pull chain device. In case of power outage, the shutter can be manually opened/closed via the pull chain to meet emergency needs during a fire.

Procurement advantages

1. Balancing Passage and Protection

Replaces traditional fire walls by meeting fire separation requirements while not affecting daily personnel and vehicle passage. Particularly suitable for open layouts in large-span spaces such as shopping malls, factories, and underground garages.

2. Adaptable to Multiple Scenarios and Environments

Optional materials available (fireproof fabric, steel composite panels, inorganic fiber composite panels, etc.), with excellent temperature resistance, corrosion resistance, and wind resistance. Can adapt to special conditions such as high-temperature workshops, damp underground garages, and flammable/explosive warehouses.

3. Stable Operation with Low Noise

Uses quiet motors + precision guide rail design for smooth, jam-free operation. Noise level below 60dB, making it suitable for noise-sensitive locations such as hospitals, schools, and office buildings.

4. Low Maintenance Costs

Wearable parts (such as steel wire ropes and seals) have strong universality and low replacement costs. Only simple cleaning and functional testing required monthly; annual professional maintenance costs are far lower than similar fire protection facilities, offering high cost-effectiveness for long-term use.

5. Long Service Life

The door body frame is made of galvanized steel or stainless steel for rust and corrosion resistance. Motors come with an extended warranty period; under normal use, service life can reach 10-15 years, reducing the cost of frequent replacements.

6. Flexible Size Customization

Can be custom-produced according to customer door opening dimensions (width 1-20m, height 1-20m). Supports special-shaped door openings (curved, corner designs) to meet the needs of unique architectural structures.