Product Feature

1. Efficient Thermal Insulation and Sealing

The door body uses high-density insulation materials such as polyurethane foam, combined with double sealing strips around the door frame, effectively blocking cold and hot air convection to reduce cold storage energy consumption. It also prevents external moisture infiltration, avoiding frost and ice buildup inside the storage.

2. Intelligent Sensor Activation

Equipped with radar, geomagnetic, or pull-rope sensors, the door automatically opens and closes based on signals from forklifts or personnel, eliminating the need for manual operation and improving warehousing efficiency. Opening/closing speeds and delayed closing times can be adjusted to suit different scenario requirements.

3. Stable and Durable Drive System

Powered by an industrial-grade reduction motor for smooth, low-noise operation, it adapts to a wide temperature range of **-30°C to +50°C**, meeting the long-term demands of high- and low-temperature cold storage. The motor features overload protection, with automatic rebound upon obstruction to prevent equipment damage or personnel injury.

4. Structural Design Tailored for Cold Chain Operations

The door frame is made of stainless steel or galvanized steel sheets for rust and corrosion resistance, capable of withstanding humid cold storage environments. The door panel surface is smooth and easy to clean, complying with hygiene standards in food, pharmaceutical, and other industries.

5. Multi-Layer Safety Protection

Standard features include anti-collision strips, emergency stop buttons, and audible/visual warning devices. Certain models offer optional infrared anti-pinch sensors for comprehensive protection of personnel and equipment during passage. Manual opening is supported in case of power failure to handle unexpected outages.

Product Description

This electric sliding cold storage door is specially designed for cold chain warehousing, food processing, pharmaceutical low-temperature storage, and similar applications, with outstanding core advantages.

The door body features high-density polyurethane foam insulation, paired with double sealing strips, effectively blocking heat exchange, reducing energy consumption, and preventing frost buildup inside the storage. Driven by an industrial-grade reduction motor, it operates smoothly with low noise, adapting to a wide temperature range of -30°C to +50°C. It includes automatic rebound upon obstruction for enhanced safety and reliability.

Supporting multiple sensing modes such as radar and geomagnetic induction, the door opens and closes automatically without manual operation, perfectly suited for frequent forklift traffic. The stainless steel frame is corrosion-resistant and easy to clean, fully complying with hygiene standards in the food and pharmaceutical industries. In case of power failure, manual opening is available to meet emergency needs.

This door is an ideal choice for efficient, energy-saving cold chain storage solutions.

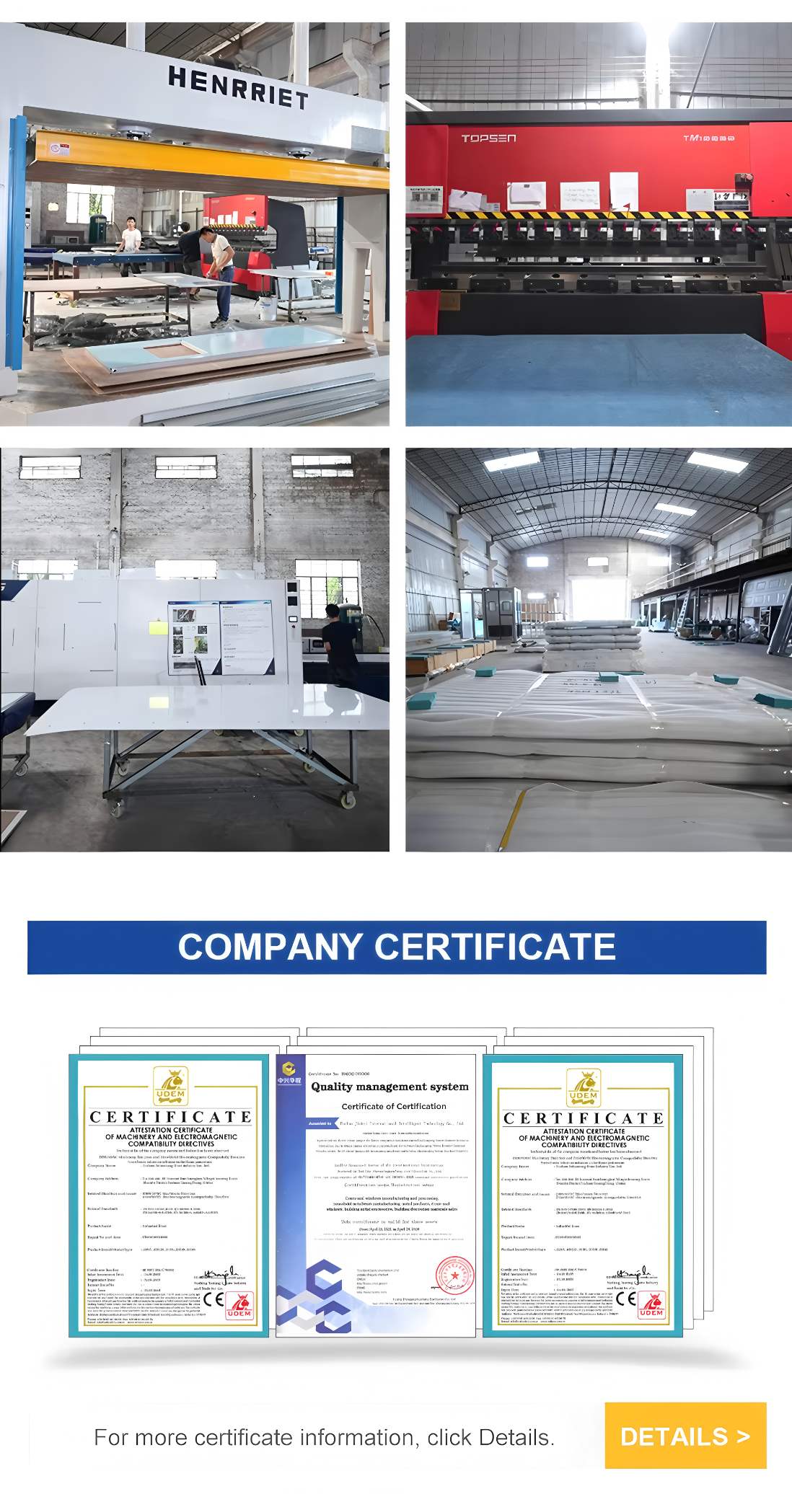

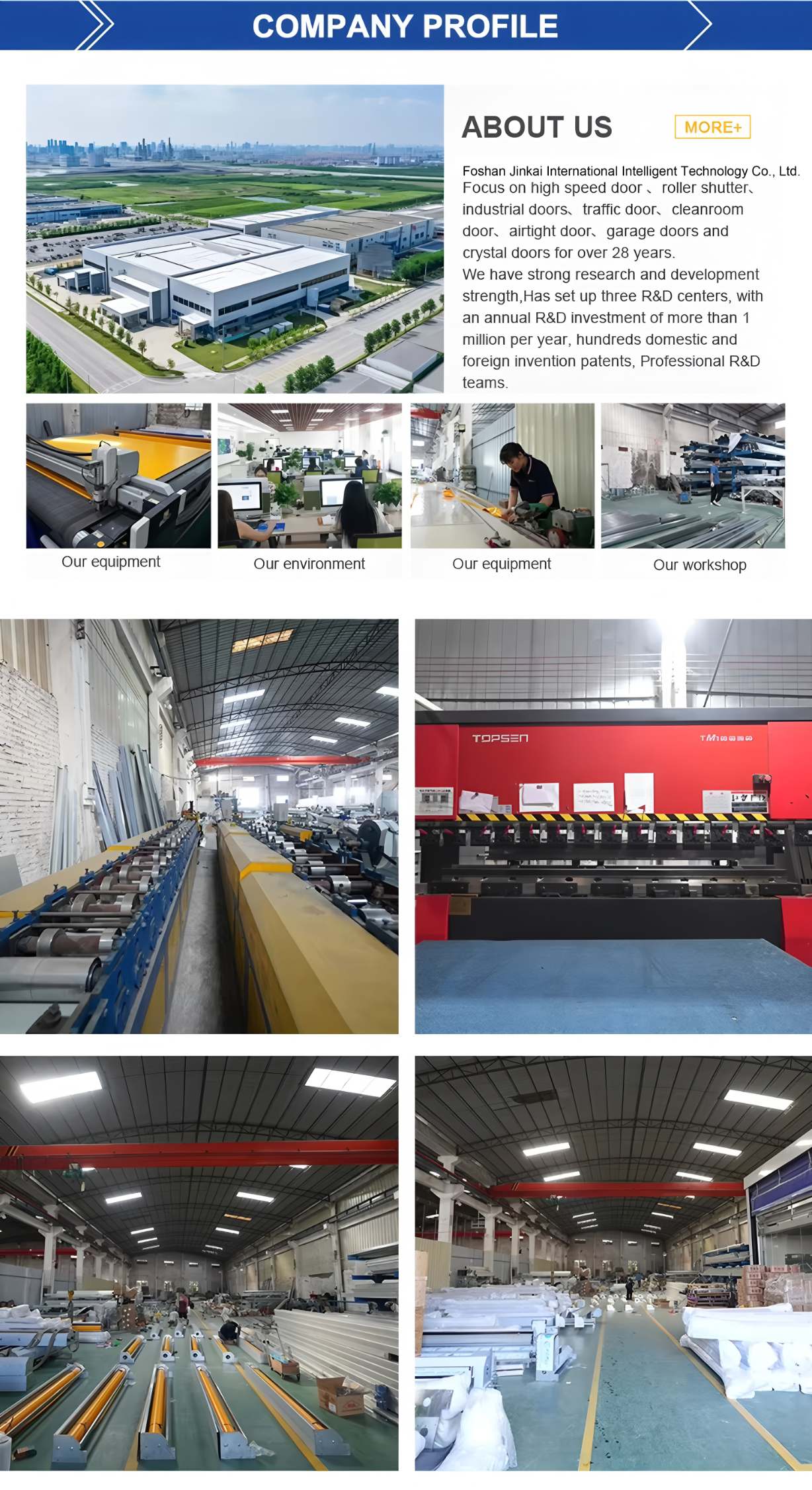

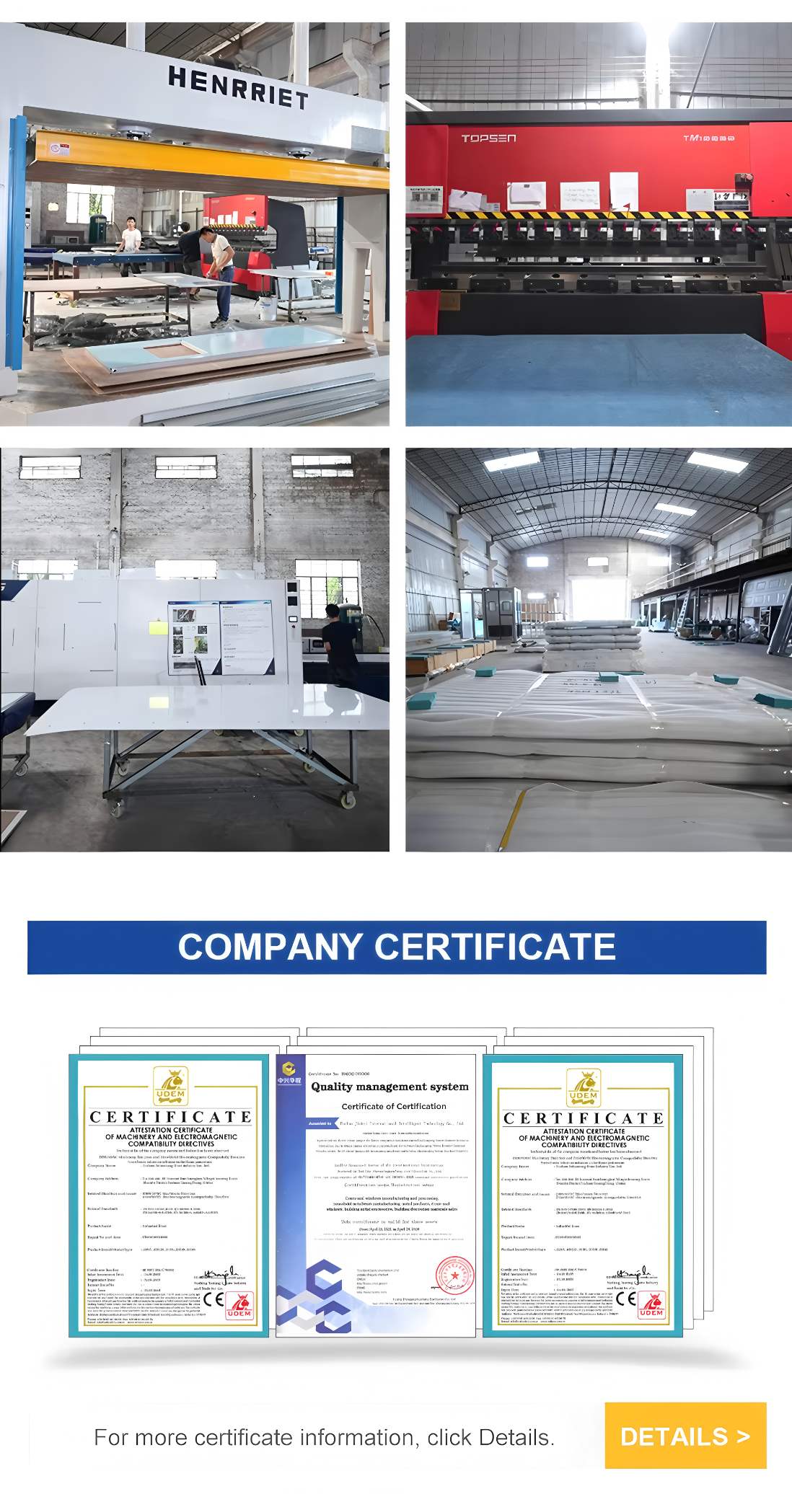

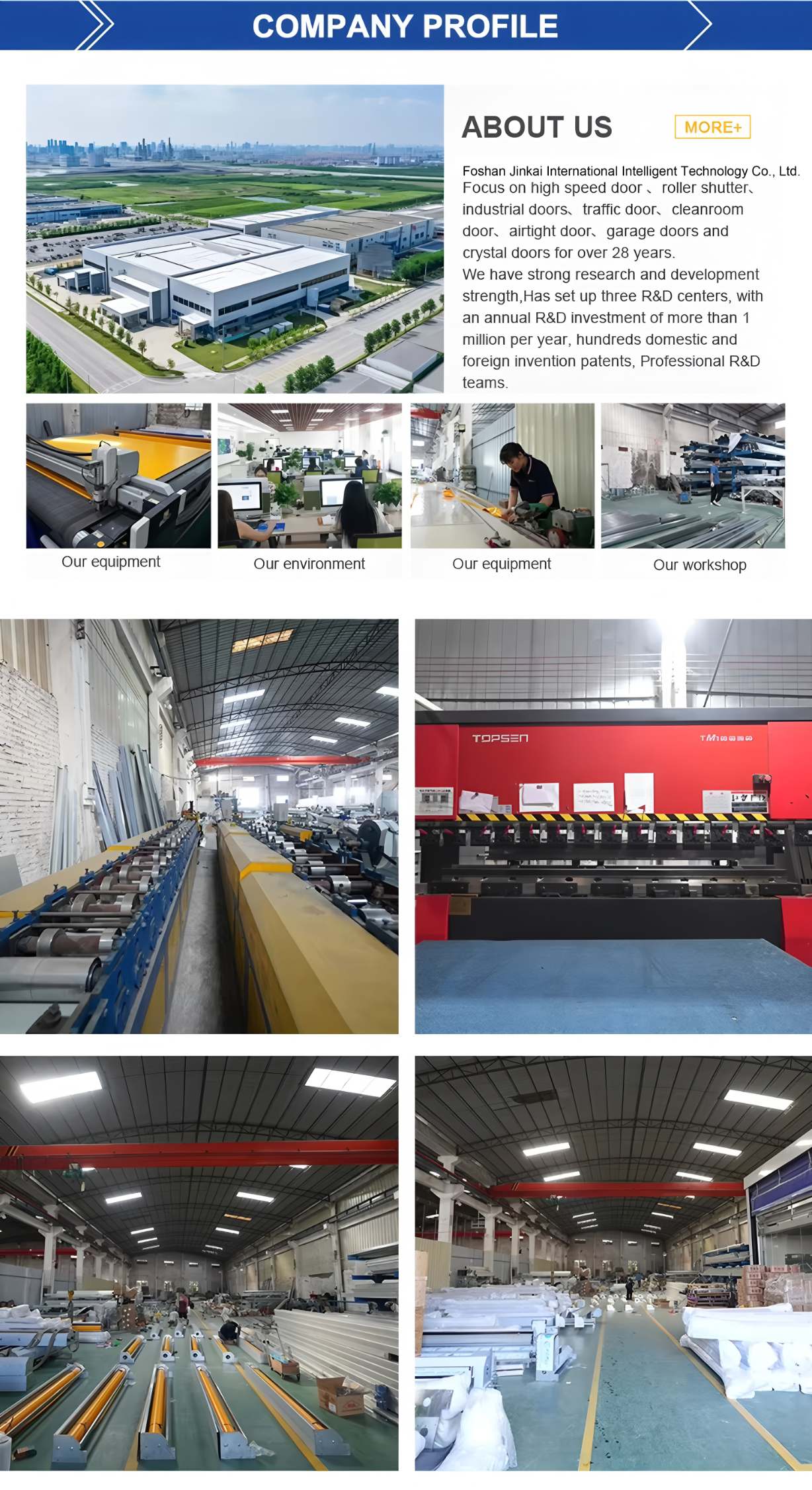

Our Workshop

Exhibition & Package & Shipping

Product Applications

1.Food Cold Chain Warehousing

Fresh and frozen storage facilities, low-temperature refrigerated warehouses, cold chain logistics transfer hubs. Suitable for frequent forklift access, minimizing cold air loss.

2.Food Processing Workshops

Quick-freezing food production lines, meat processing workshops, fruit and vegetable pre-cooling rooms. Meets requirements for hygienic cleaning and constant-temperature operations.

3.Pharmaceutical Low-Temperature Storage

Vaccine cold storage, biopharmaceutical refrigerated warehouses, low-temperature pharmaceutical warehouses. Complies with GMP standards in the pharmaceutical industry, ensuring stable storage environment.

4.Chemical Raw Material Low-Temperature Storage

Warehouses for chemical raw materials requiring low-temperature and light-protected storage. Corrosion-resistant materials withstand certain chemical environment erosion.

5.Supermarket Cold Chain Back-of-House

Fresh produce cold storage and frozen goods stocking areas in large supermarkets. Intelligent sensing improves restocking efficiency.

6.Cold Chain Distribution Centers

Sorting cold storage in regional cold chain distribution hubs. Suitable for high-frequency loading and unloading scenarios.

After-sales Service

1. Free Installation, Commissioning, and Training

Our professional technical team will visit your site to provide free installation and commissioning of the door body and control system, ensuring that all operating parameters meet usage standards. At the same time, we offer one-on-one operational training for logistics and equipment management teams, covering daily opening/closing operations, interlock settings, basic troubleshooting, and more. Operation manuals and maintenance guidelines will also be provided.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, while the complete unit has a 1-year warranty. During the warranty period, any non-human-induced faults will be repaired or have parts replaced free of charge.

3. Regular Inspections and Preventive Maintenance

During the warranty period, a technician will visit every 6 months to perform one inspection, checking door sealing performance, sensor sensitivity, motor operating condition, etc. Aging wearable parts (such as brush seals) will be replaced in a timely manner to eliminate potential issues. After the warranty period expires, an annual maintenance agreement can be signed to enjoy discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

We ensure timely availability of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

We provide lifetime free technical consultation to address any issues encountered during use. For future upgrades to door interlock functions (such as integration with new access control or fire safety systems), cost-price technical upgrade services are available to meet the needs of hospital intelligent transformation projects.

FAQS

1. Q: How effective is the insulation of this door? What is the lowest temperature cold storage environment it can handle?

A: The door body is filled with a high-density polyurethane insulation layer and equipped with double sealing strips, achieving a cold air loss rate as low as 5% or below. It adapts to a wide temperature range of -30°C to +50°C, fully meeting the demands of ultra-low-temperature cold storage.

2. Q: Can the door's operating speed be adjusted? Will frequent opening and closing affect its service life?

A: It supports 3-level speed adjustment for opening and closing, suitable for different scenarios involving forklifts or personnel. The drive motor uses industrial-grade wear-resistant gears, with a designed service life of ≥80,000 cycles, ensuring stable operation even under high-frequency use.

3. Q: How do you open the door during a power outage? Is there an emergency opening/closing mechanism?

A: It comes standard with a manual clutch device—simply pull the clutch handle during a power outage to manually push or pull the door. Optionally, a UPS emergency power supply can be added, allowing 1-2 automatic open/close operations even without power.

4. Q: What dimensions need to be reserved before installation? Do you provide on-site measurement services?

A: Reserve space for the door opening dimensions, side installation areas, and top motor mounting position—specific parameters can be found in the product installation manual. We offer free on-site measurement services, with a professional team creating a customized installation plan based on site conditions.

5. Q: Does the door have an anti-pinch function? Will it automatically stop if it encounters an obstacle?

A: Standard features include infrared anti-pinch sensors and obstruction rebound function. If an obstacle is detected during operation, the door immediately stops and reverses. It is also equipped with audible and visual warning devices to enhance passage safety.

Procurement Advantages

1. Energy Saving and Consumption Reduction, Lowering Operating Costs

High-density polyurethane insulation filling + double sealing strips, resulting in cold loss rate as low as 5% or below, significantly reducing the start-stop frequency of cold storage compressors, and substantially lowering electricity costs over long-term use.

2. Intelligent Adaptation, Improving Operational Efficiency

Supports multiple sensing modes including radar, geomagnetic, and pull-rope; doors open and close automatically when forklifts or personnel pass through, eliminating the need for manual operation. Adjustable door opening and closing speeds adapt to high-frequency access scenarios, reducing waiting time during loading and unloading.

3. Stable and Durable, Suitable for Harsh Environments

Industrial-grade reduction motor, resistant to low temperatures and moisture, capable of stable operation in a wide temperature range of -30°C to +50°C. Door frame made of stainless steel or galvanized steel sheet, rust-proof and corrosion-resistant, offering long service life and low maintenance costs.

4. Safety Protection, Mitigating Operational Risks

Standard configuration includes infrared anti-pinch sensors, obstacle rebound function, emergency stop button, and audio-visual warning devices. In case of power outage, the door can be opened manually to handle unexpected power failures, providing comprehensive protection for the safe passage of personnel and equipment.

5. Flexible Customization, Meeting Diverse Needs

Supports full-dimensional customization of door size, materials, insulation thickness, sensing methods, etc., suitable for various scenarios such as food cold chain, pharmaceutical storage, and chemical low-temperature warehouses. Complies with industry hygiene and safety standards.