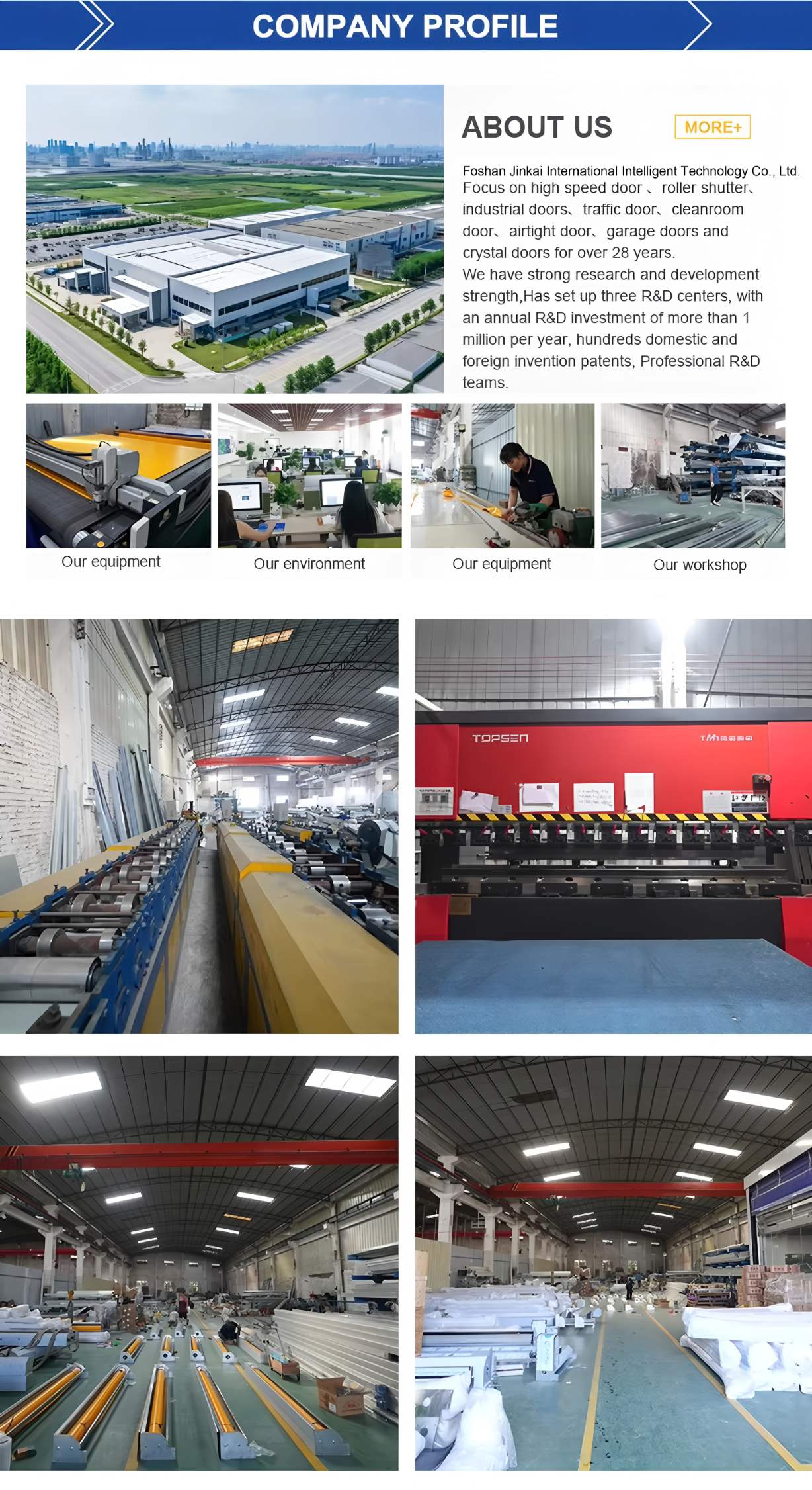

Product Feature

1. High Impact Resistance & Damage Prevention

Made from high-strength tempered glass or PC polycarbonate sheets, resistant to collisions and abrasion. Ideal for high-frequency industrial scenarios involving forklift traffic and cargo handling, it is not prone to cracking or shattering under external impacts.

2. Clear Visibility & Excellent Light Transmission

Light transmittance exceeds 85% with no visual distortion, allowing clear observation of personnel and vehicle movement on both sides of the door. This enables early risk prediction and prevents collisions during door opening and closing.

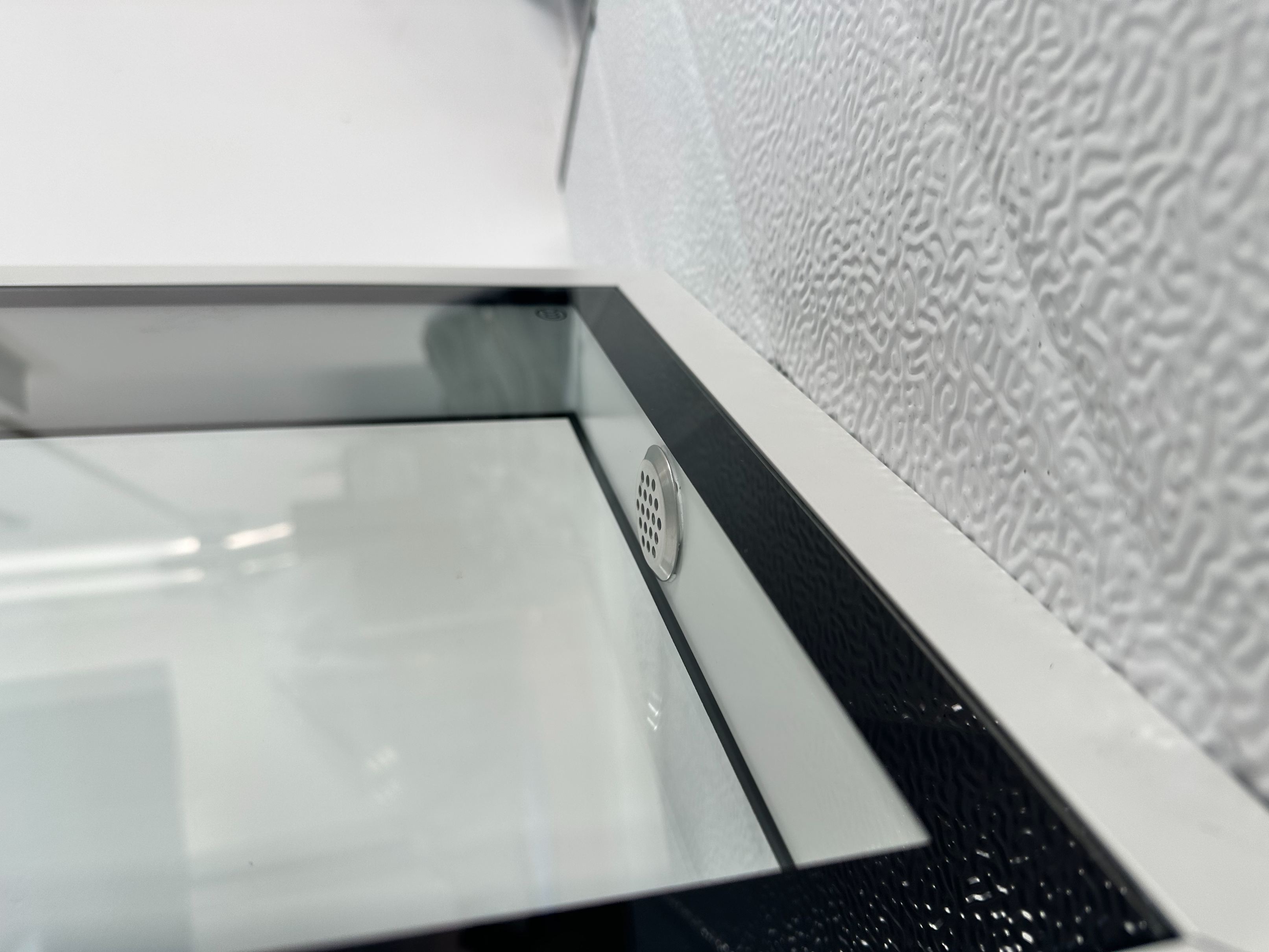

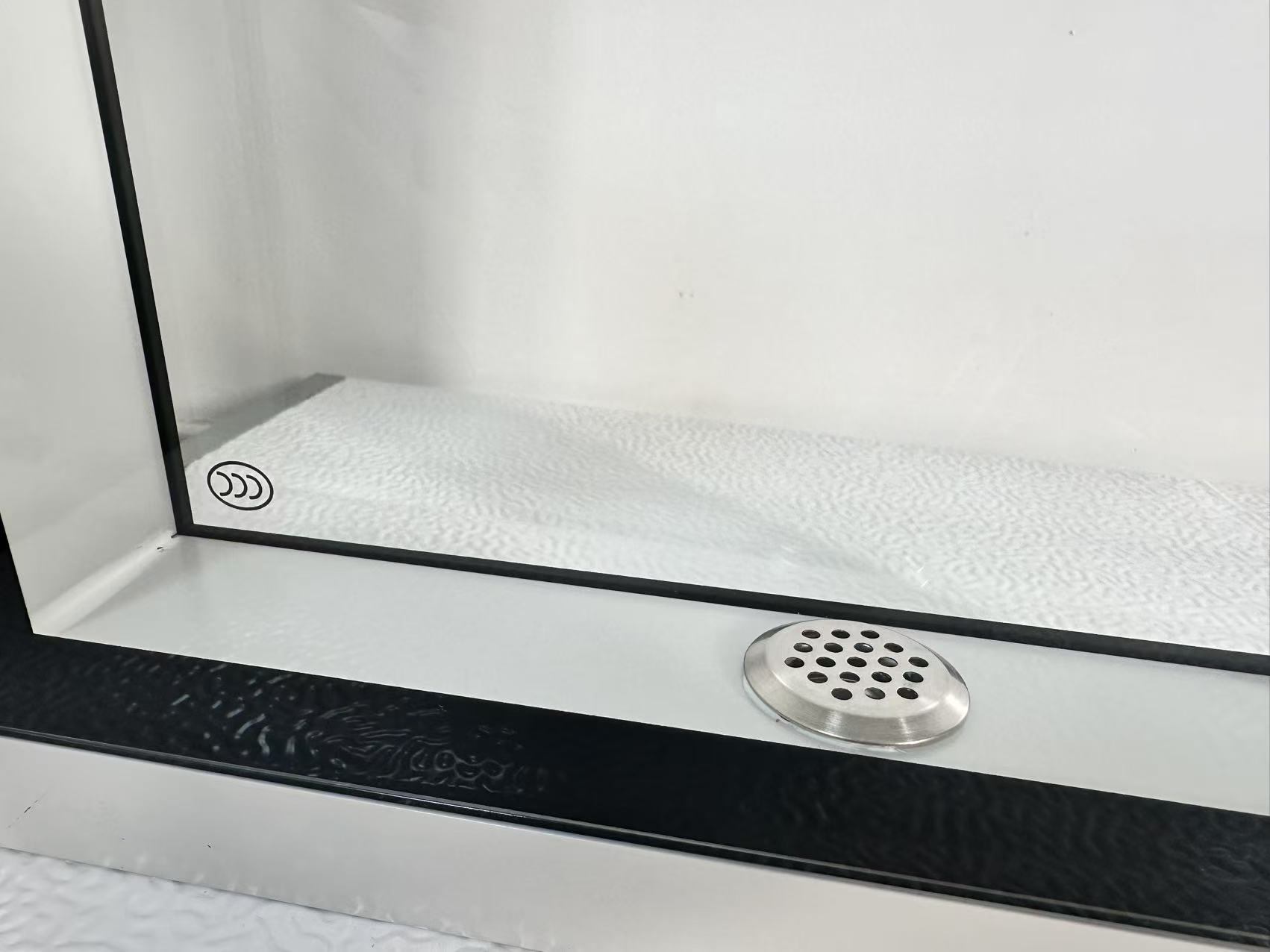

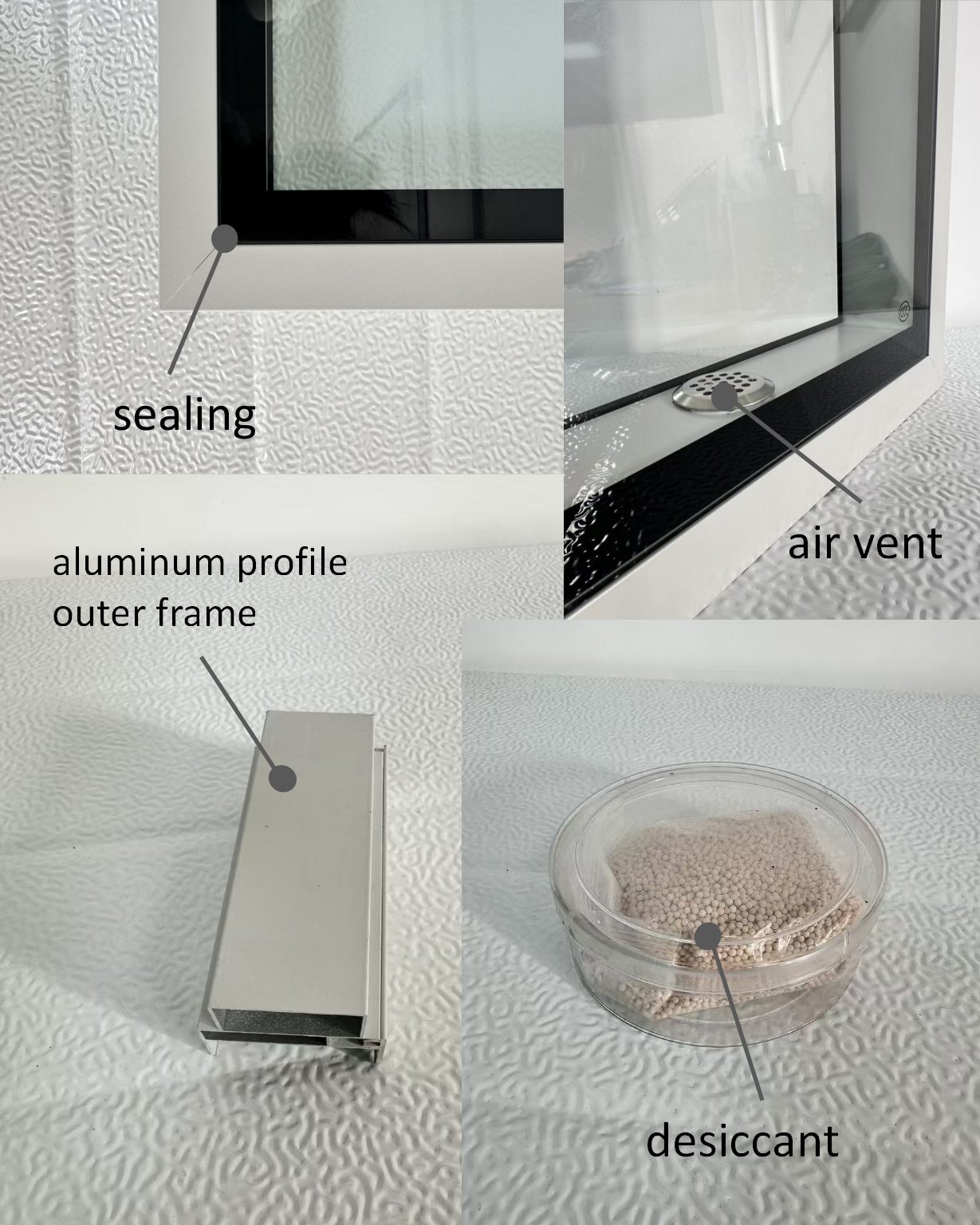

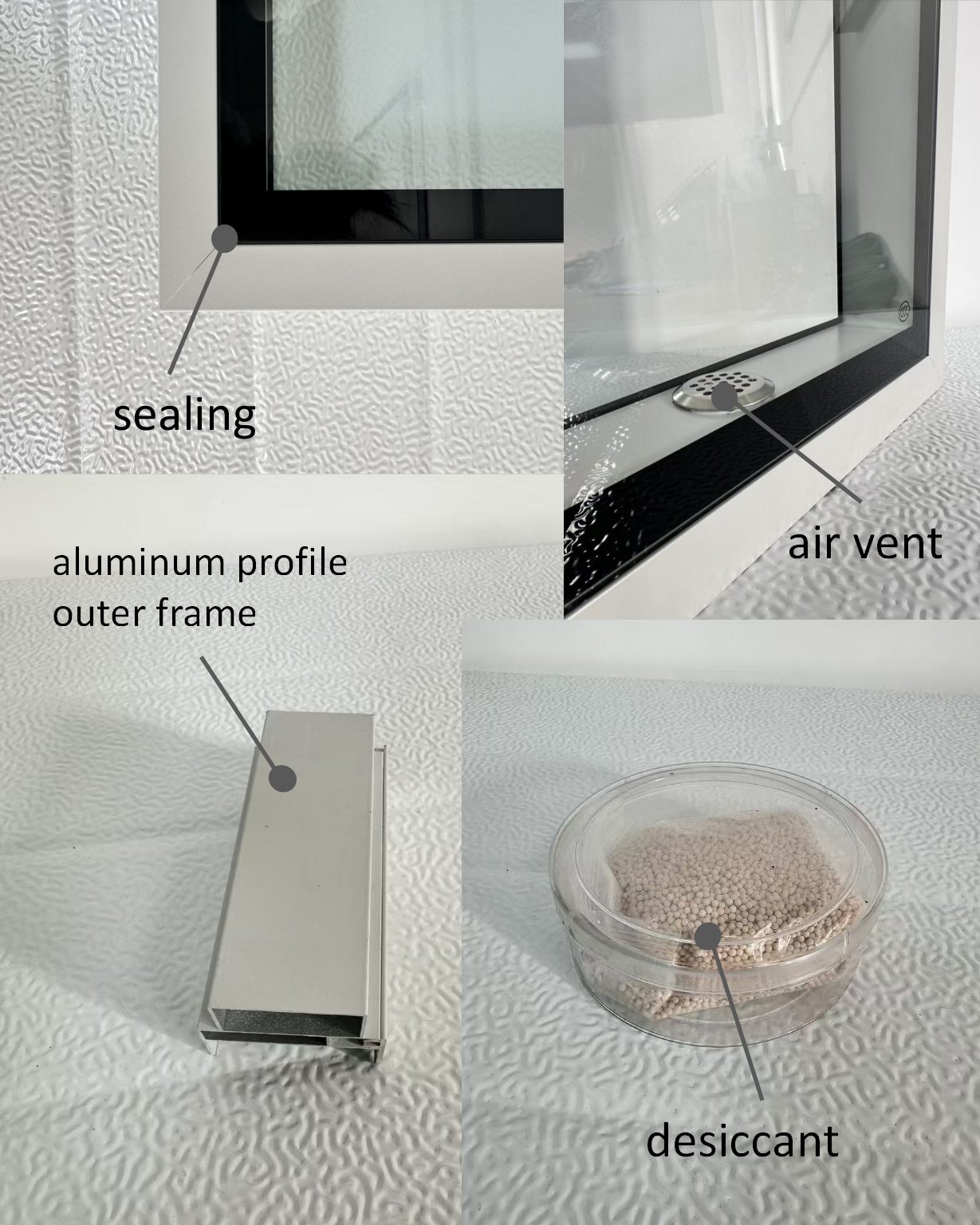

3. Sealed Dust-Proof & Waterproof/Moisture-Proof

Equipped with professional sealing strips around the edges that fit tightly with the door frame, effectively blocking dust, rainwater, and moisture from entering the facility. Suitable for industries with high cleanliness requirements, such as food processing and electronics manufacturing.

4. Easy Installation & Strong Compatibility

Standardized mounting hole dimensions allow seamless integration with mainstream industrial doors such as PVC rapid doors, stainless steel impact doors, and industrial sectional doors. Supports factory pre-installation or retrofitting without major structural modifications to the door body.

5. Safety Protection & User-Friendly Design

Edges are rounded and polished to prevent injuries from bumps. Certain models offer optional anti-fog coating to address fogging in low-temperature, high-humidity environments, ensuring all-day clear visibility.

Product Description

Our industrial door observation window is engineered for high-intensity workshop environments, blending durability, safety and practicality in one compact design.

Crafted from premium tempered glass or PC endurance board, it boasts exceptional impact resistance, resisting collisions from forklifts and heavy cargo. With over 85% light transmittance, it delivers distortion-free visibility, allowing real-time monitoring of personnel and vehicle movement to prevent accidents.

Equipped with professional sealing strips, it effectively blocks dust, rain and moisture, ideal for clean rooms in food and electronics industries. The standardized size ensures easy installation on PVC high-speed doors, stainless steel crash doors and other industrial door types, with no major structural modifications required. Rounded edges eliminate collision risks, while optional anti-fog coating guarantees clear vision in humid conditions.

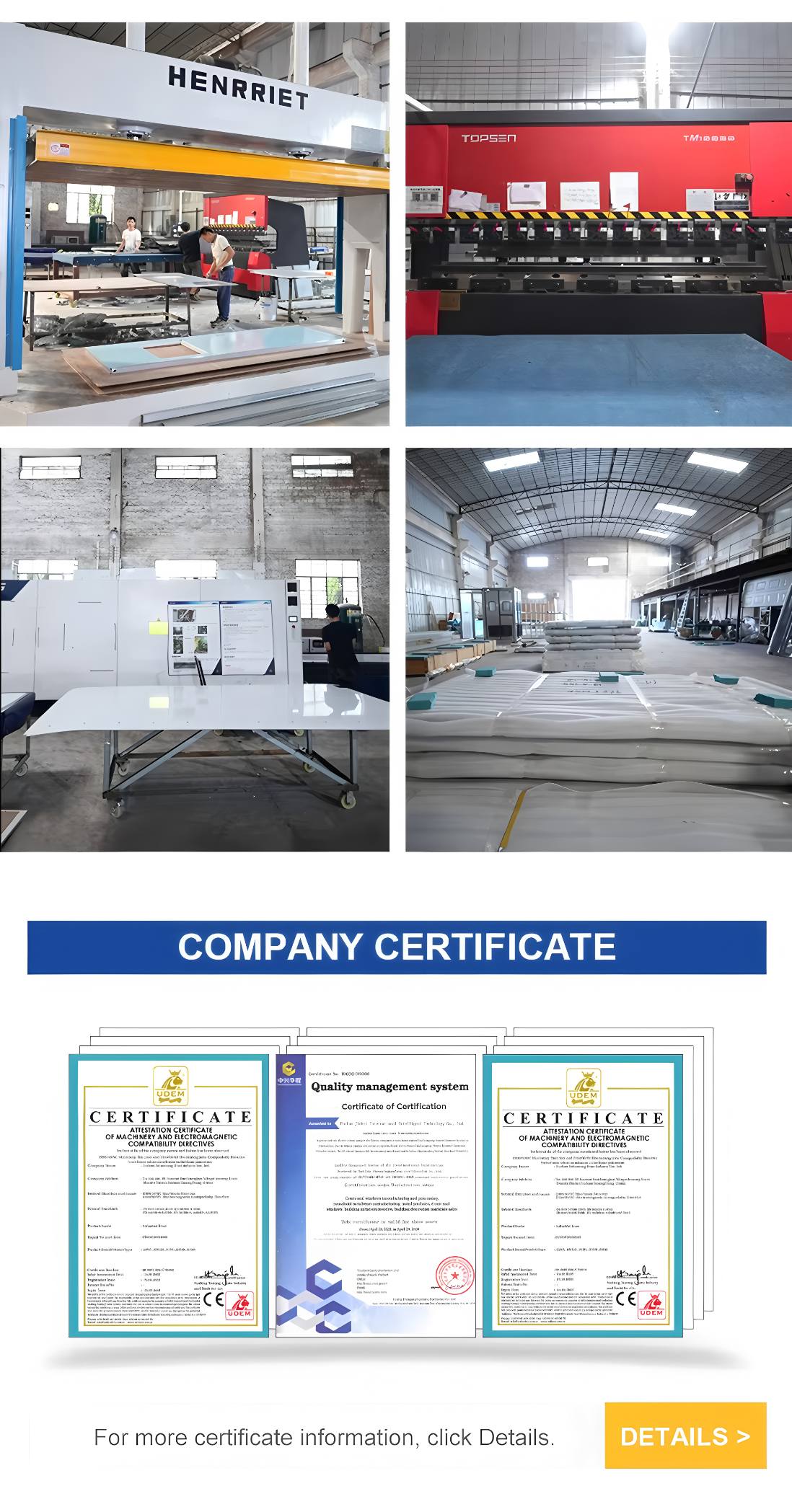

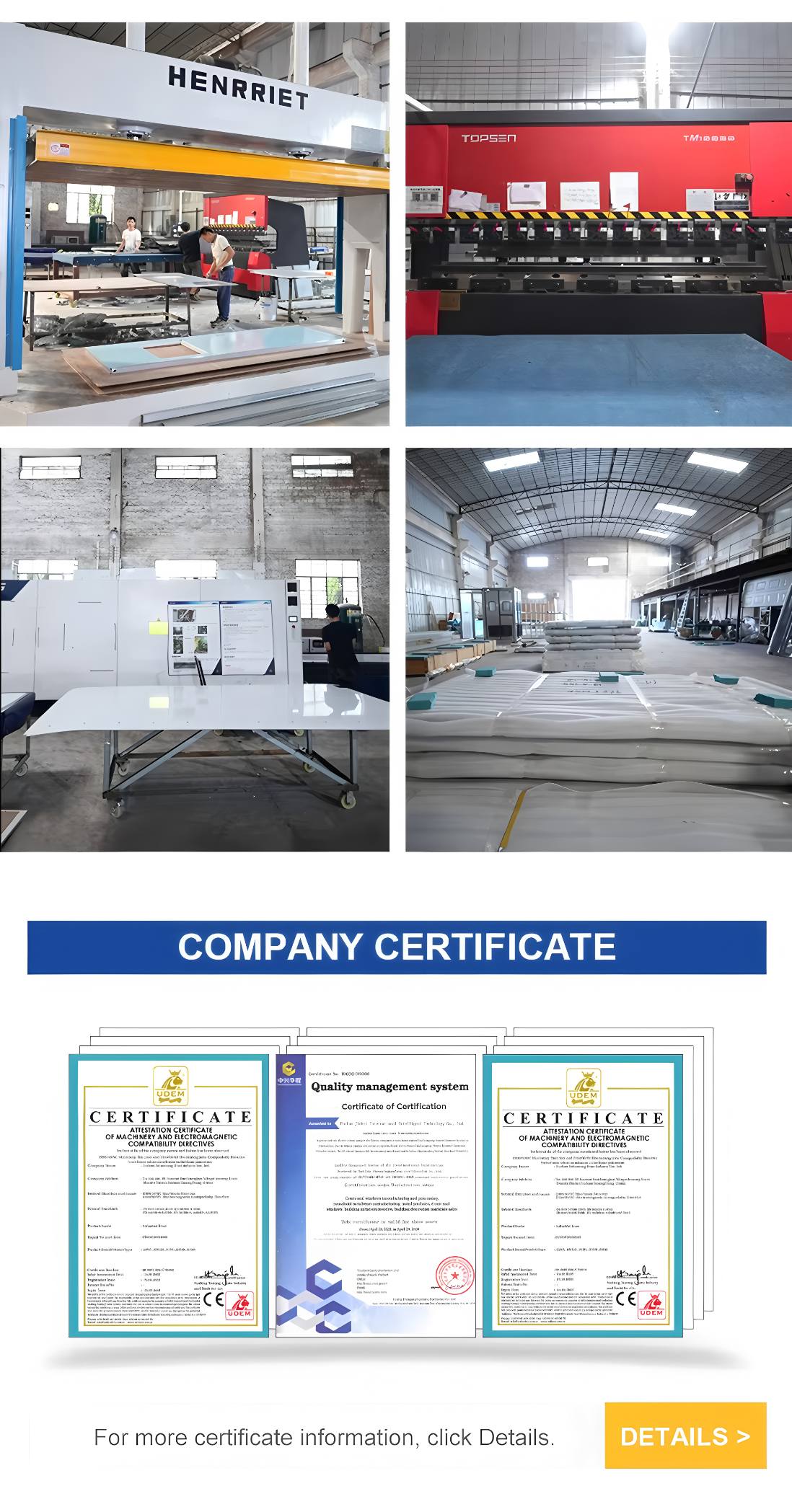

Production Process

Package & Shipping

Product Applications

1. Food Processing Workshop

Compatible with PVC rapid doors and stainless steel anti-collision doors. The observation window allows real-time monitoring of material transport and personnel movement inside and outside the door. The sealed dust-proof design prevents dust from contaminating ingredients, ensuring the cleanliness of the production environment.

2. Electronic Component Factory

High requirements for environmental cleanliness and anti-static protection. The observation window provides clear monitoring of forklift operations and cargo transfer on both sides of the door, enabling early avoidance of collision risks while blocking external dust from entering the workshop and affecting precision component production.

3. Cold Chain Warehousing and Logistics Center

Paired with rapid doors designed for cold storage. The observation window allows viewing of cargo stacking and loading/unloading progress inside the warehouse without opening the door, reducing cold air loss and energy consumption. Certain anti-fog models address visibility blurring issues in low-temperature, high-humidity environments.

4. Automotive Manufacturing and Assembly Workshop

Frequent movement of forklifts and AGV robots within the workshop. The observation window clearly predicts the movement trajectories of equipment on both sides of the door, preventing collisions with vehicles or robotic arms during door opening and closing, thereby enhancing production line safety.

5. Pharmaceutical Clean Workshop

Complies with GMP production standards. The observation window enables real-time monitoring of personnel and material flow inside and outside the door. The sealed waterproof design prevents moisture and dust intrusion, ensuring the sterility and stability of the pharmaceutical production environment.

After-sales Service

1. Free Installation, Commissioning, and Training

Our professional technical team will visit your site to provide free installation and commissioning of the door body and control system, ensuring that all operating parameters meet usage standards. At the same time, we offer one-on-one operational training for logistics and equipment management teams, covering daily opening/closing operations, interlock settings, basic troubleshooting, and more. Operation manuals and maintenance guidelines will also be provided.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, while the complete unit has a 1-year warranty. During the warranty period, any non-human-induced faults will be repaired or have parts replaced free of charge.

3. Regular Inspections and Preventive Maintenance

During the warranty period, a technician will visit every 6 months to perform one inspection, checking door sealing performance, sensor sensitivity, motor operating condition, etc. Aging wearable parts (such as brush seals) will be replaced in a timely manner to eliminate potential issues. After the warranty period expires, an annual maintenance agreement can be signed to enjoy discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

We ensure timely availability of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

We provide lifetime free technical consultation to address any issues encountered during use. For future upgrades to door interlock functions (such as integration with new access control or fire safety systems), cost-price technical upgrade services are available to meet the needs of hospital intelligent transformation projects.

FAQS

1. Q: Is tempered glass or PC polycarbonate better for the observation window?

A: Tempered glass offers higher hardness and superior light transmittance, making it suitable for clean workshops with minimal forklift collisions. PC polycarbonate provides better impact resistance, ideal for heavy-duty industrial scenarios with frequent handling and forklift traffic. You can choose based on your needs; we also support customized double-layer composite materials.

2. Q: What if there is air or dust leakage after installation?

A: First, check whether the sealing strips are aged or misaligned. They can be replaced with EPDM sealing strips and re-compressed. If the gap between the frame and the door body is too large, fill it with specialized sealant to ensure a tight fit.

3. Q: How to prevent fogging on the observation window in low-temperature, high-humidity environments?

A: Choose models with anti-fog coating, or opt for a double-layer hollow structure to reduce the temperature difference between inside and outside and prevent condensation. For daily cleaning, use neutral detergents to avoid damaging the anti-fog coating.

4. Q: Can it be adapted to non-standard size industrial doors?

A: Yes. Provide parameters such as door opening dimensions and frame material, and we support customization of non-standard specifications to match various door types, including PVC rapid doors and stainless steel impact doors, without requiring major modifications to the door body.

5. Q: How long is the warranty for the observation window? Can human-induced damage be repaired?

A: Standard warranty is 12 months, covering quality issues related to materials and workmanship. Human-induced damage (e.g., impact or improper installation) can be repaired for a fee, with replacement parts charged at cost price and after-sales response within 24 hours.

6. Q: How about the light transmittance and impact resistance?

A: Light transmittance ≥85% with no distortion. Both tempered glass and PC polycarbonate resist collisions from forklifts and cargo, are not prone to shattering, and are suitable for high-frequency industrial operations.

Procurement Advantages

1. Cost-Effective with High Value

Factory-direct supply eliminates middleman markups, with tiered discounts for bulk purchases. Free samples are provided (customer covers shipping only), reducing upfront selection and trial costs.

2. Diverse Materials with On-Demand Customization

Supports material options such as tempered glass, PC polycarbonate sheets, and double-layer hollow anti-fog structures. Customizable for non-standard sizes, anti-static or anti-fog coatings, and compatible with various door types including PVC rapid doors and stainless steel impact doors.

3. Stable Delivery with Transparent Timelines

Standard models are in ample stock for shipment within 3-5 working days. Customized orders have clear production cycles (7-10 working days), with full order progress tracking available to avoid delays in workshop renovation schedules.

4. Quality Assurance and Worry-Free After-Sales

Products pass impact resistance and sealing performance tests for industrial door accessories, with a 12-month warranty. The after-sales team responds within 24 hours, offering free installation guidance. Human-induced damage qualifies for replacement parts at cost price.

5. One-Stop Supporting Solutions for Ease and Efficiency

Complementary accessories such as industrial door sealing strips and reinforced frames can be purchased together. We provide technical solutions for door opening and installation compatibility, eliminating the need to coordinate with multiple suppliers.