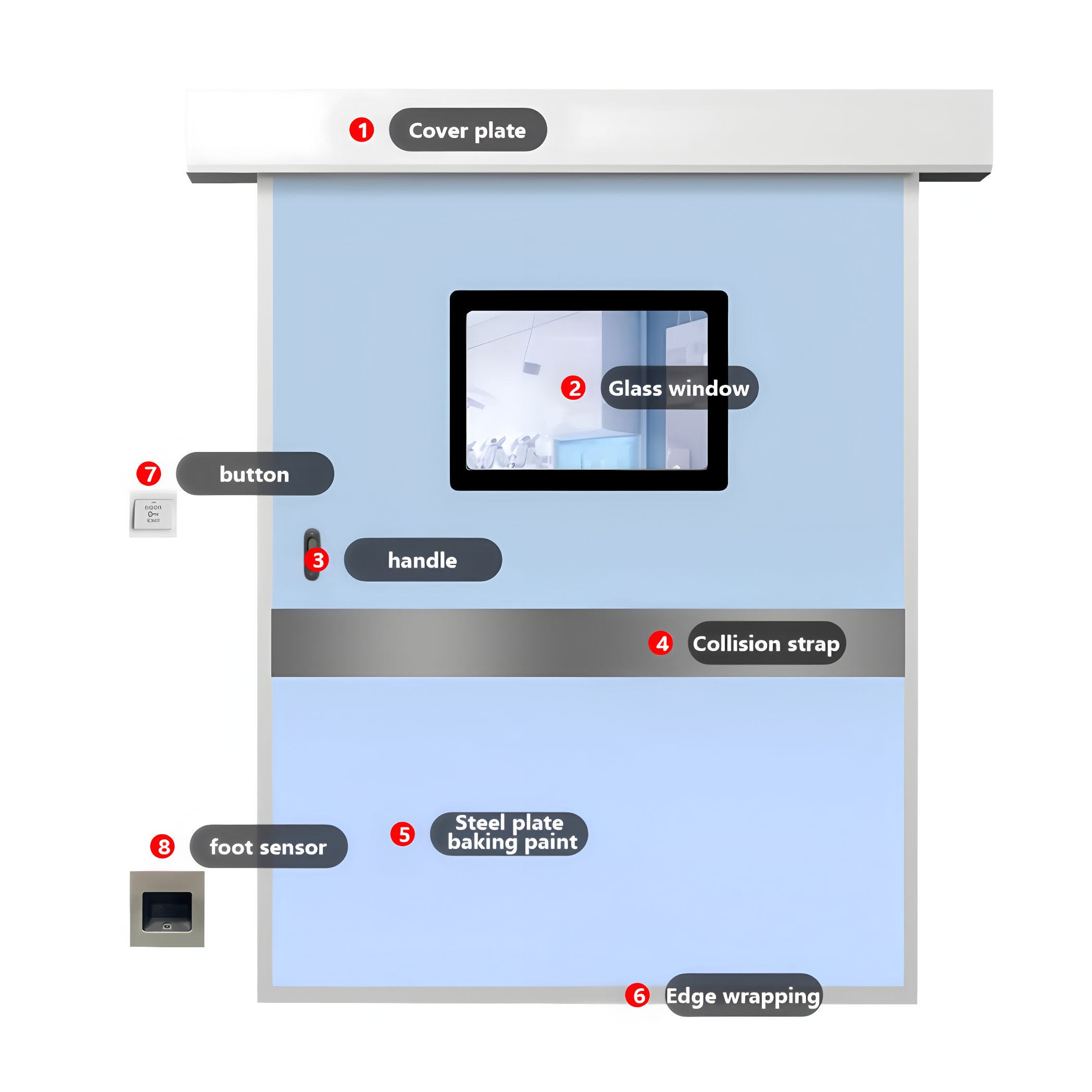

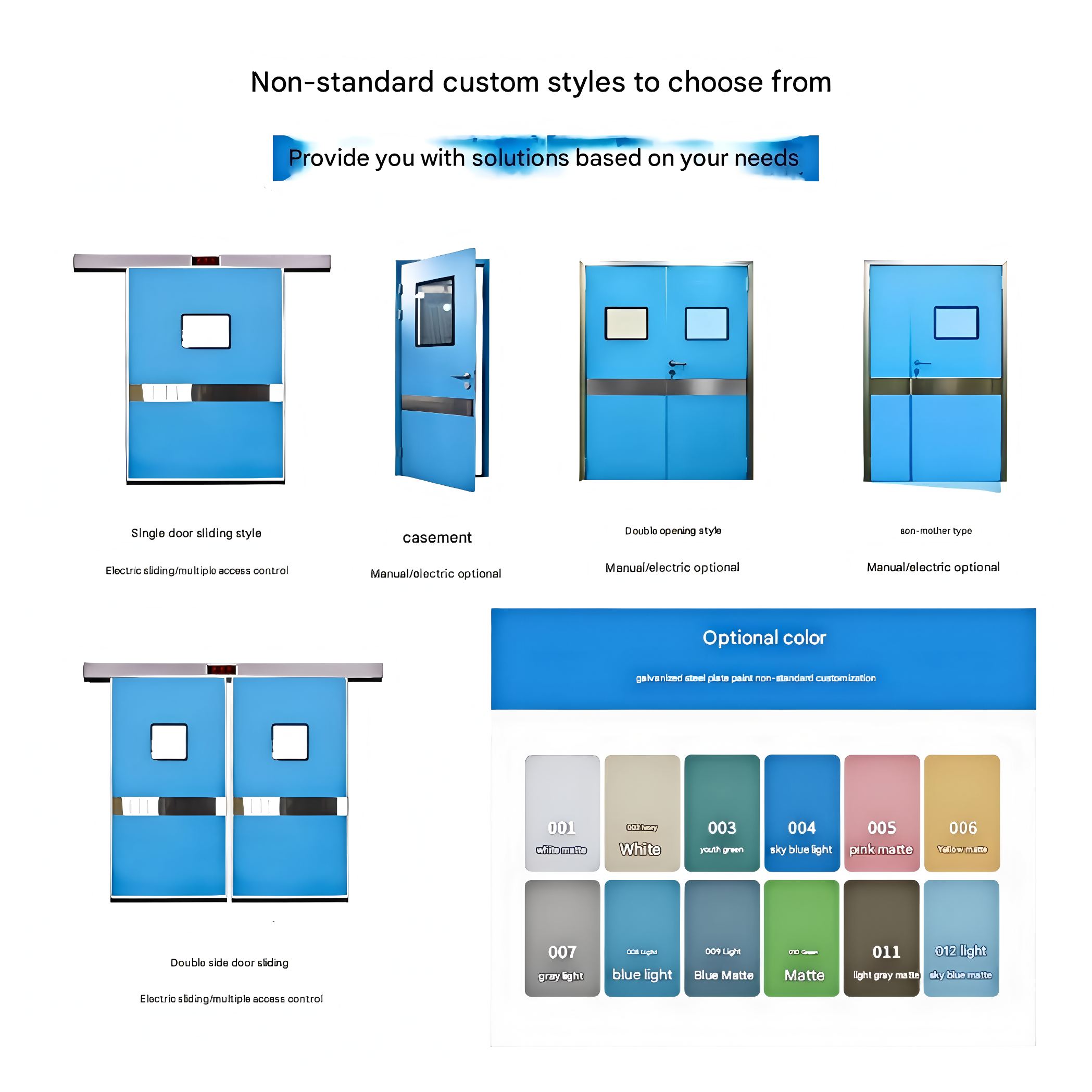

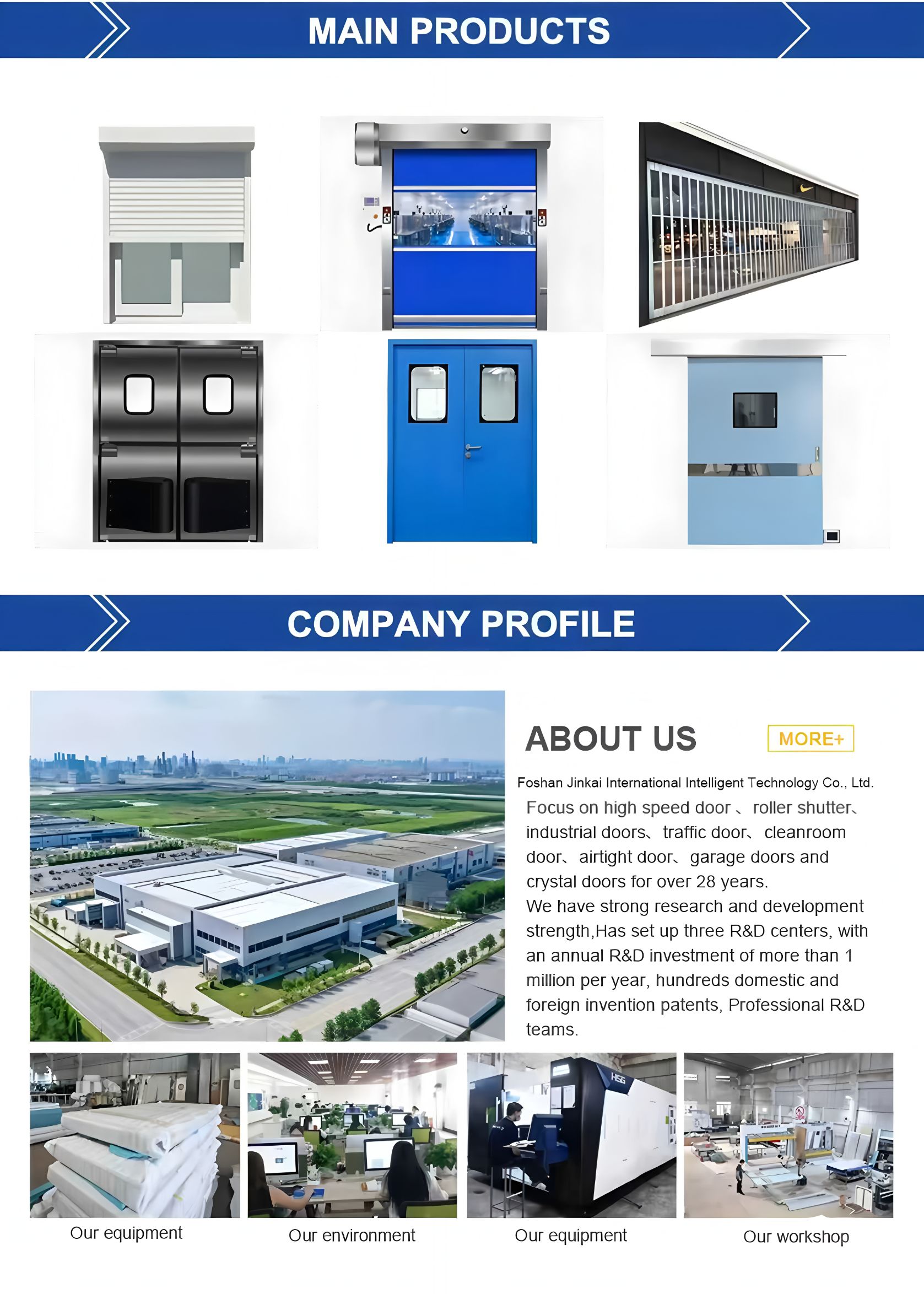

Product Feature

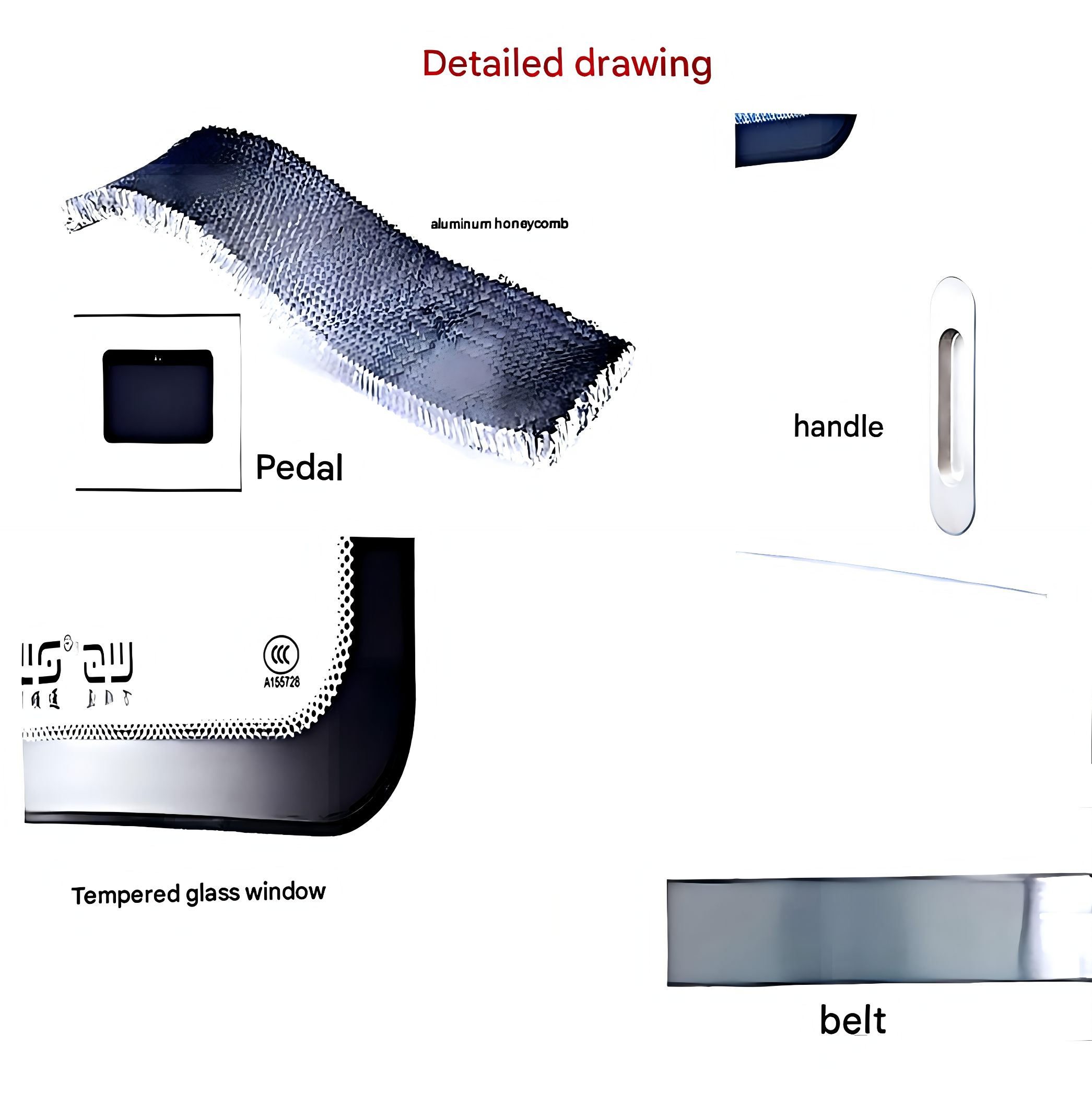

1. High-Level Sealing Protection

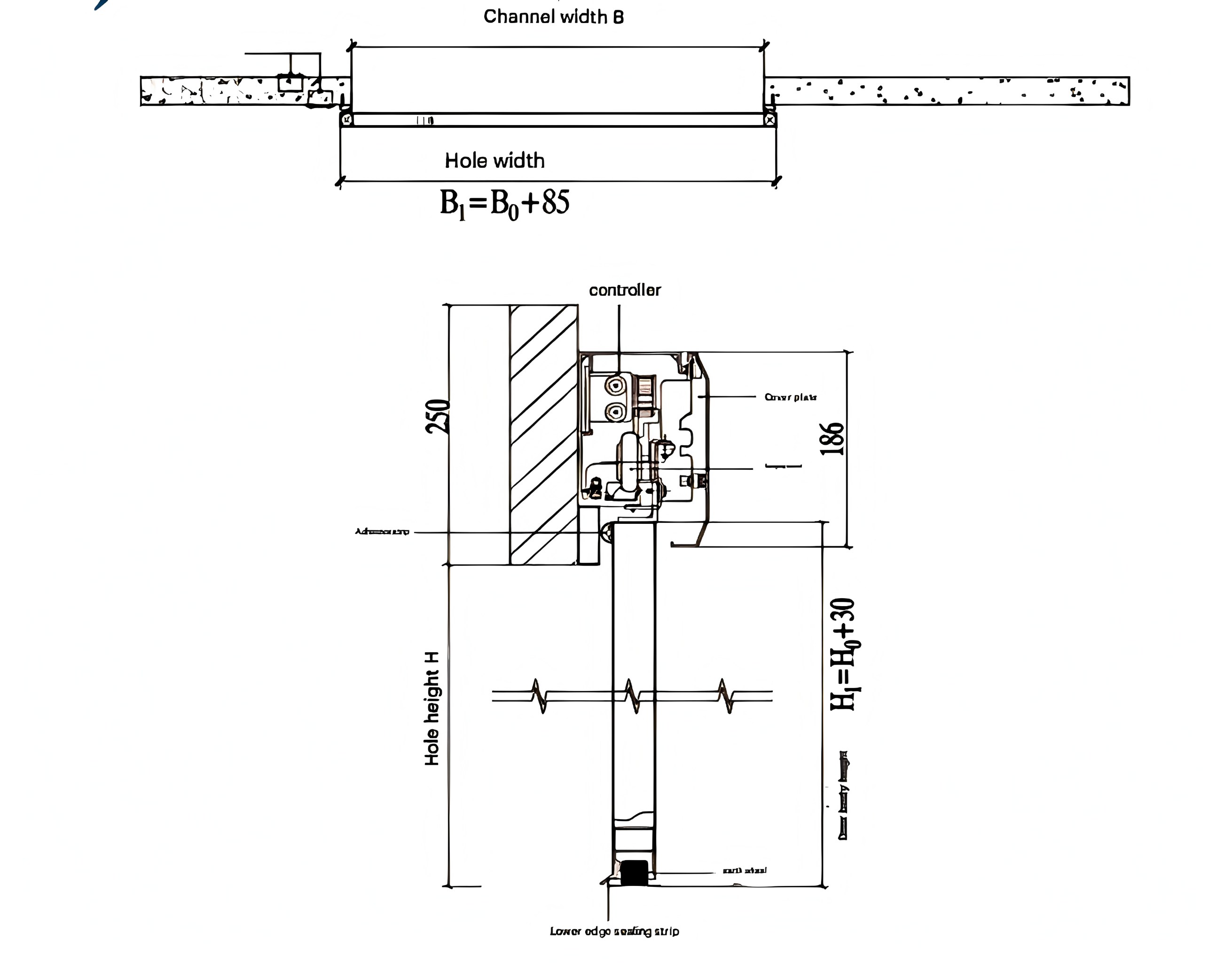

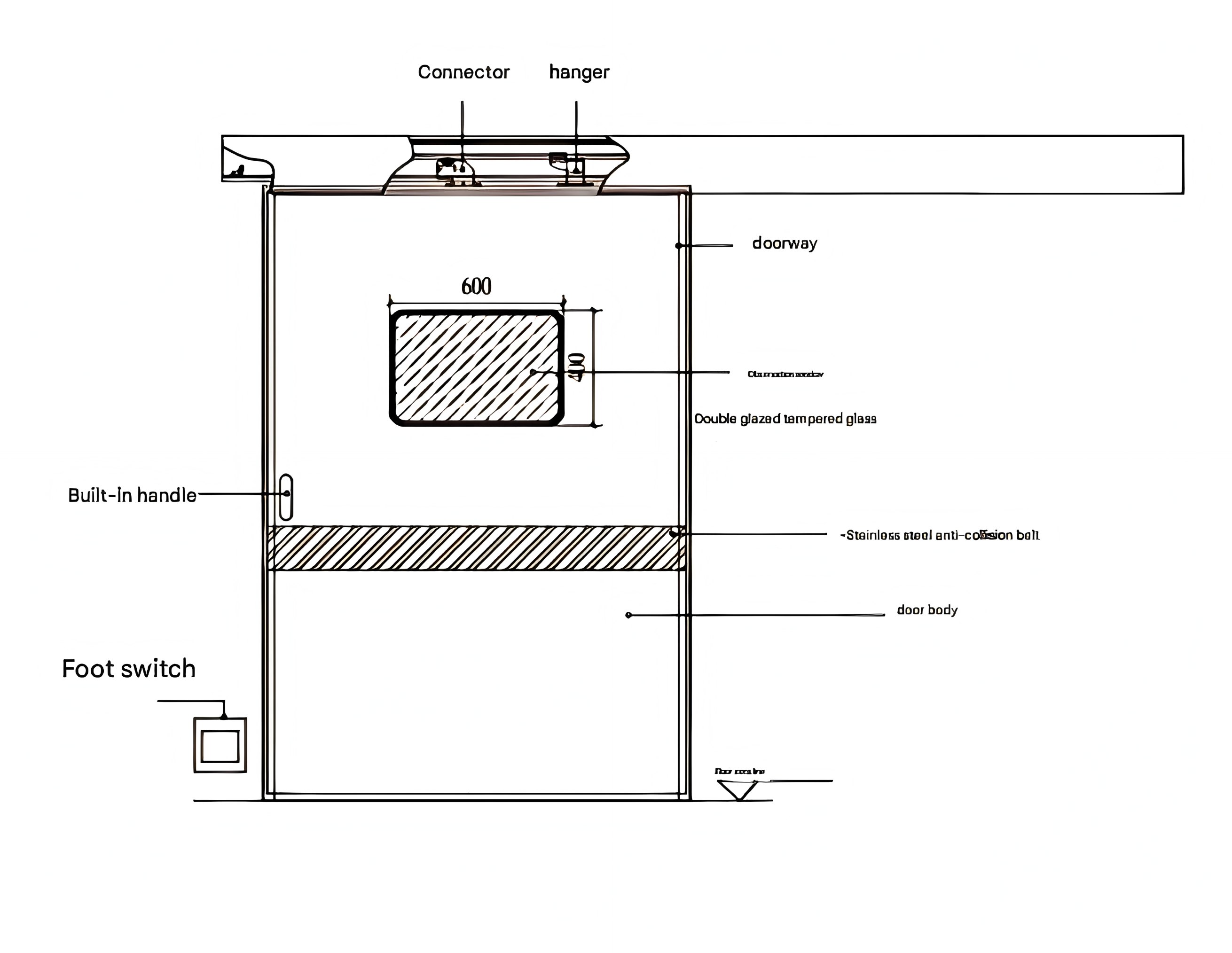

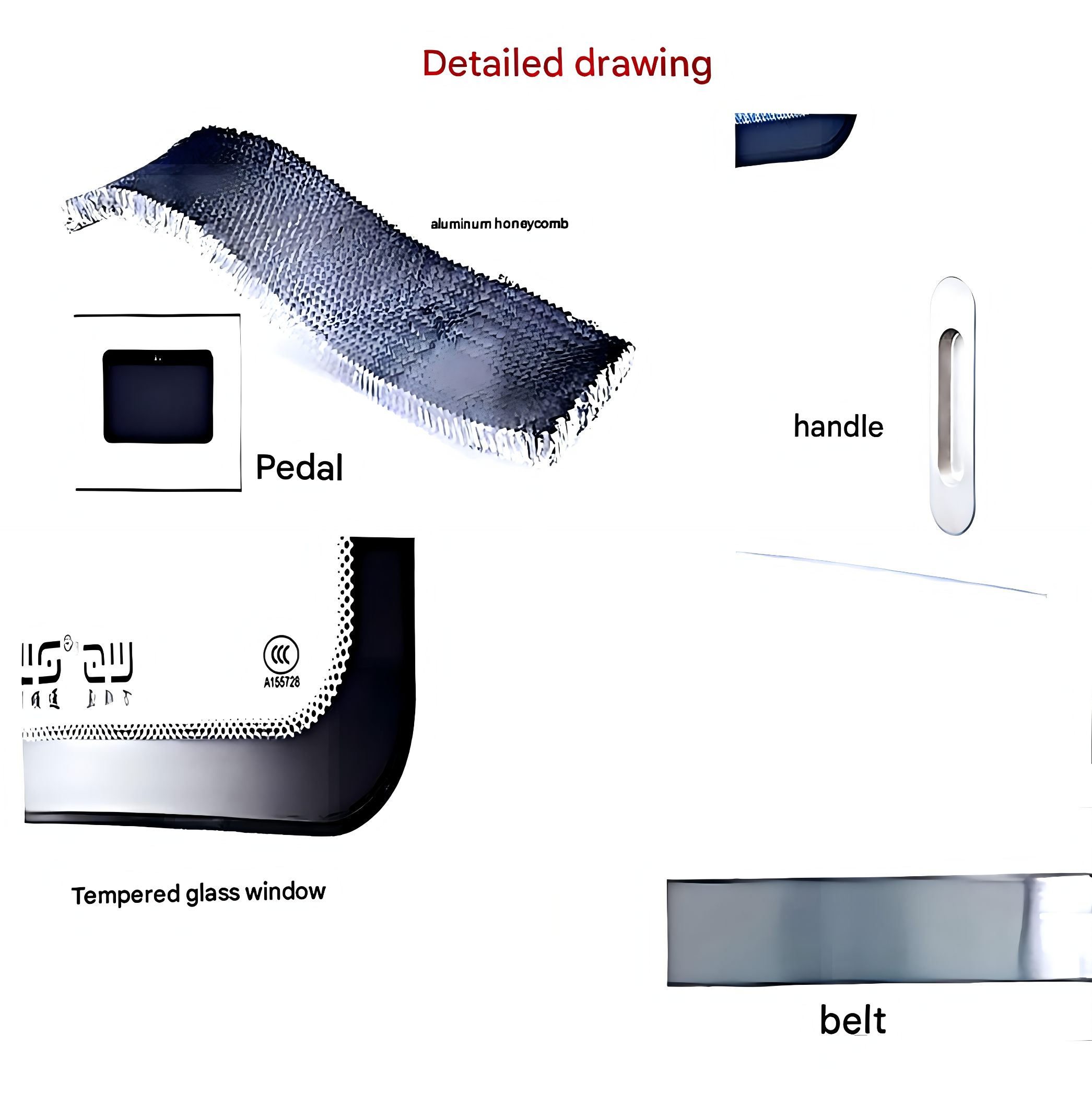

The door frame, door panel edges, and bottom are equipped with EPDM (ethylene propylene diene monomer) rubber sealing strips or adjustable brush seals, providing multi-directional blocking of dust, moisture, and cold/hot air convection. This makes it suitable for scenarios with high environmental isolation requirements, such as cleanrooms and cold-chain storage facilities.

2. Intelligent Automation

Control supports multiple triggering methods, including radar, geomagnetic, and infrared beam sensors. It can integrate with workshop PLC systems, access control, and fire safety systems to achieve unattended automatic opening and closing. It also allows customizable settings for door opening/closing delays and operating speeds to match production line rhythms.

3. Superior Safety Protection Performance

Standard features include infrared safety light curtains and anti-pinch sensors; the door will immediately stop or reverse operation upon detecting obstacles. Certain models are equipped with emergency manual operation devices, allowing manual pushing/pulling during power outages to ensure the safety of personnel and equipment.

4. High Space Utilization

Adopts a lateral sliding opening mechanism, requiring no overhead lifting space or front swing clearance. It is ideal for installation in locations with limited headroom above the door opening but ample side space, without affecting workshop equipment layout or passage planning.

5. Energy-Saving, Low-Consumption, and High Durability

Excellent sealing performance combined with rapid opening and closing functions reduces cold/hot air exchange between indoor and outdoor environments, lowering energy consumption for air conditioning and heating. The door frame and tracks are made of galvanized steel or stainless steel, offering corrosion and rust resistance, adaptability to humid and dusty industrial environments, and low maintenance costs.

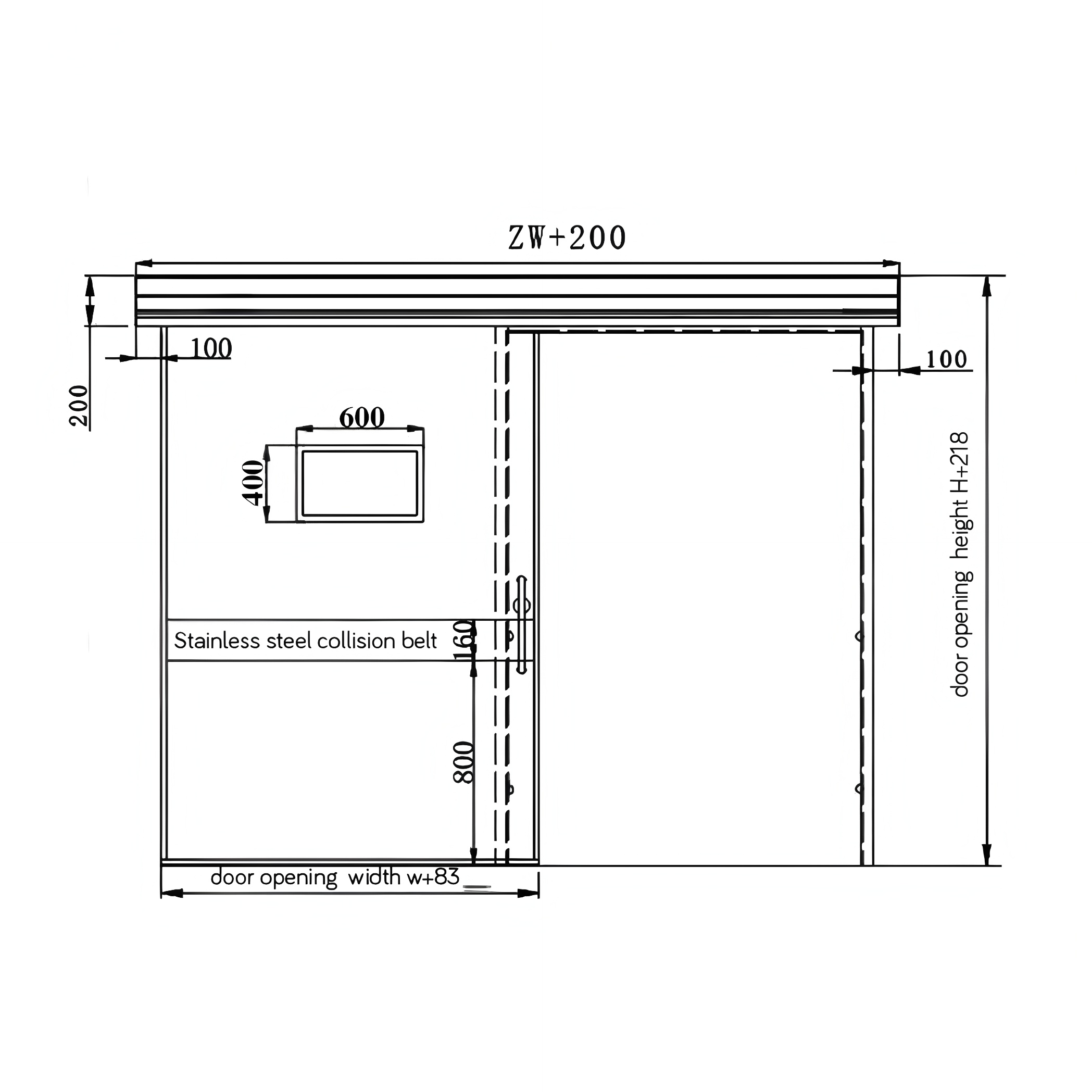

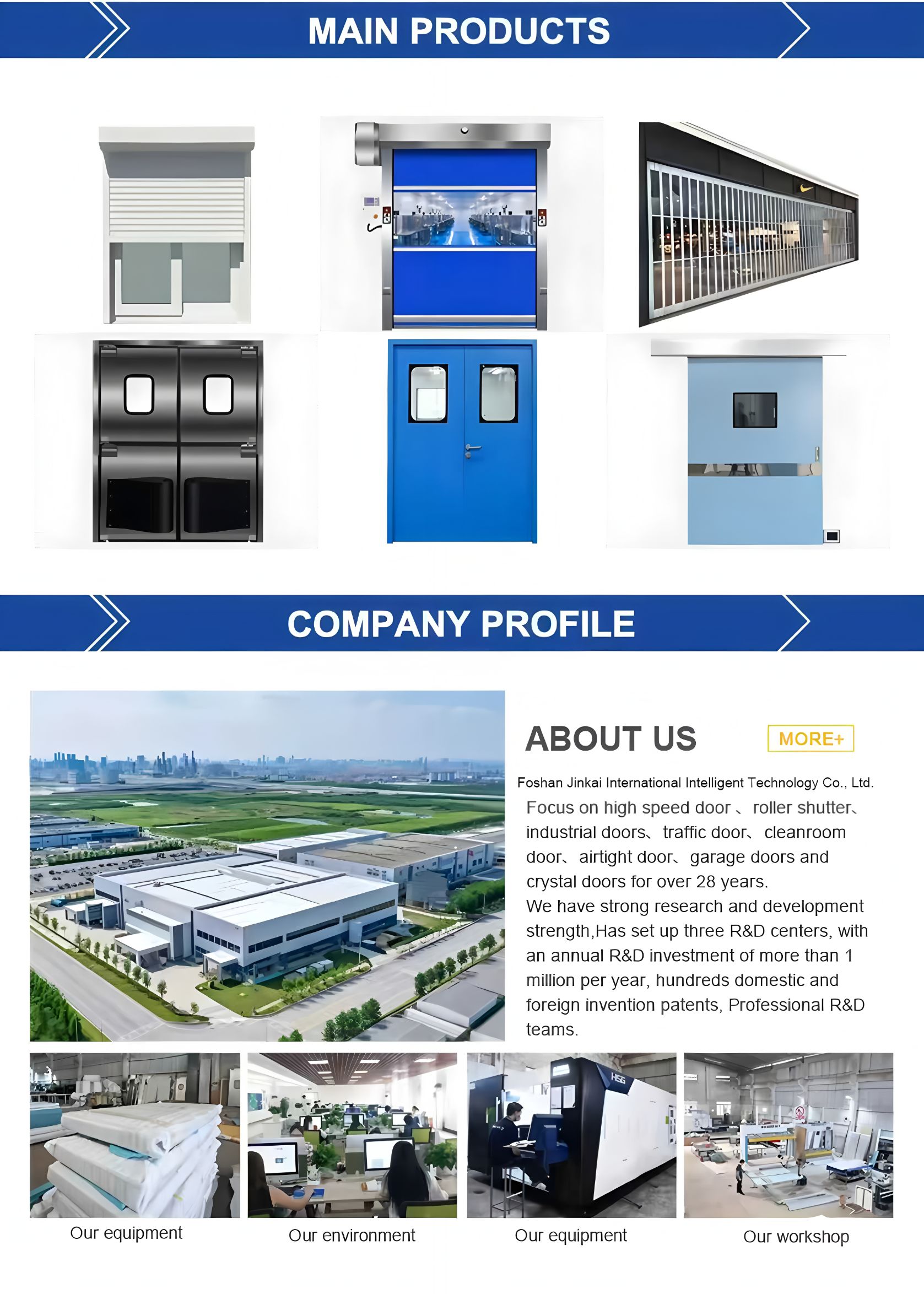

Product Description

This automatic sealed sliding door is an ideal choice for efficient isolation and intelligent access in industrial environments. It is specifically designed for scenarios with stringent environmental control requirements, such as cleanrooms, cold-chain storage facilities, and dust-intensive workshops.

The door features a multi-directional sealing structure with EPDM rubber sealing strips and an adjustable bottom seal pad, effectively blocking dust, moisture, and cold/hot air convection. Combined with rapid opening and closing functions, it significantly reduces energy loss.

The intelligent control system supports multiple triggering methods, including radar and geomagnetic sensors, and can integrate with PLC and fire safety systems for unattended automated operation. Standard infrared safety light curtains and anti-pinch sensors ensure the safety of personnel and equipment.

The lateral sliding design requires no additional clearance space, making it suitable for confined installation areas. The door frame and tracks are constructed from galvanized steel or stainless steel, offering excellent corrosion resistance and easy maintenance. This provides a stable and reliable environmental isolation solution for industrial production.

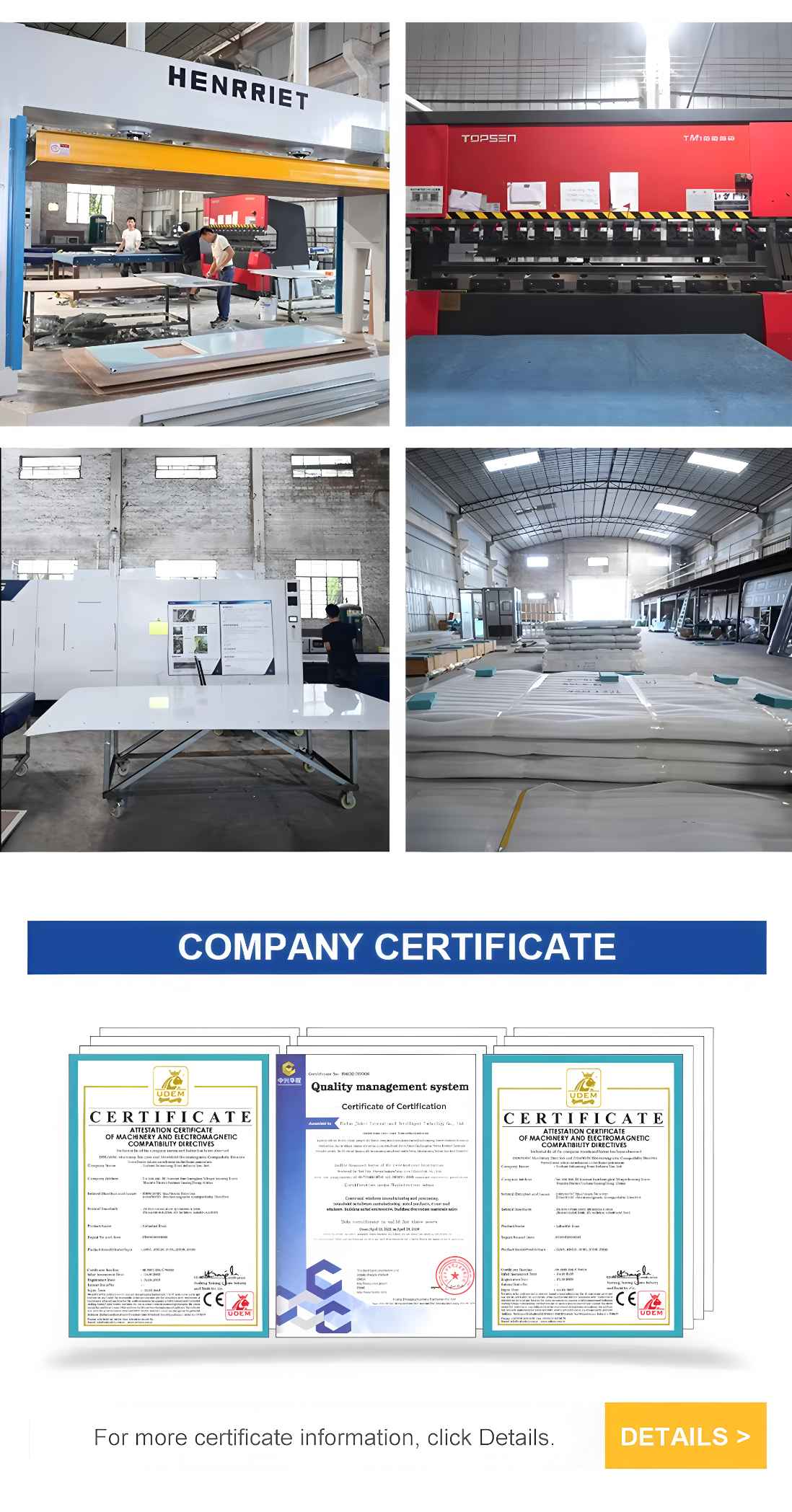

Production Process

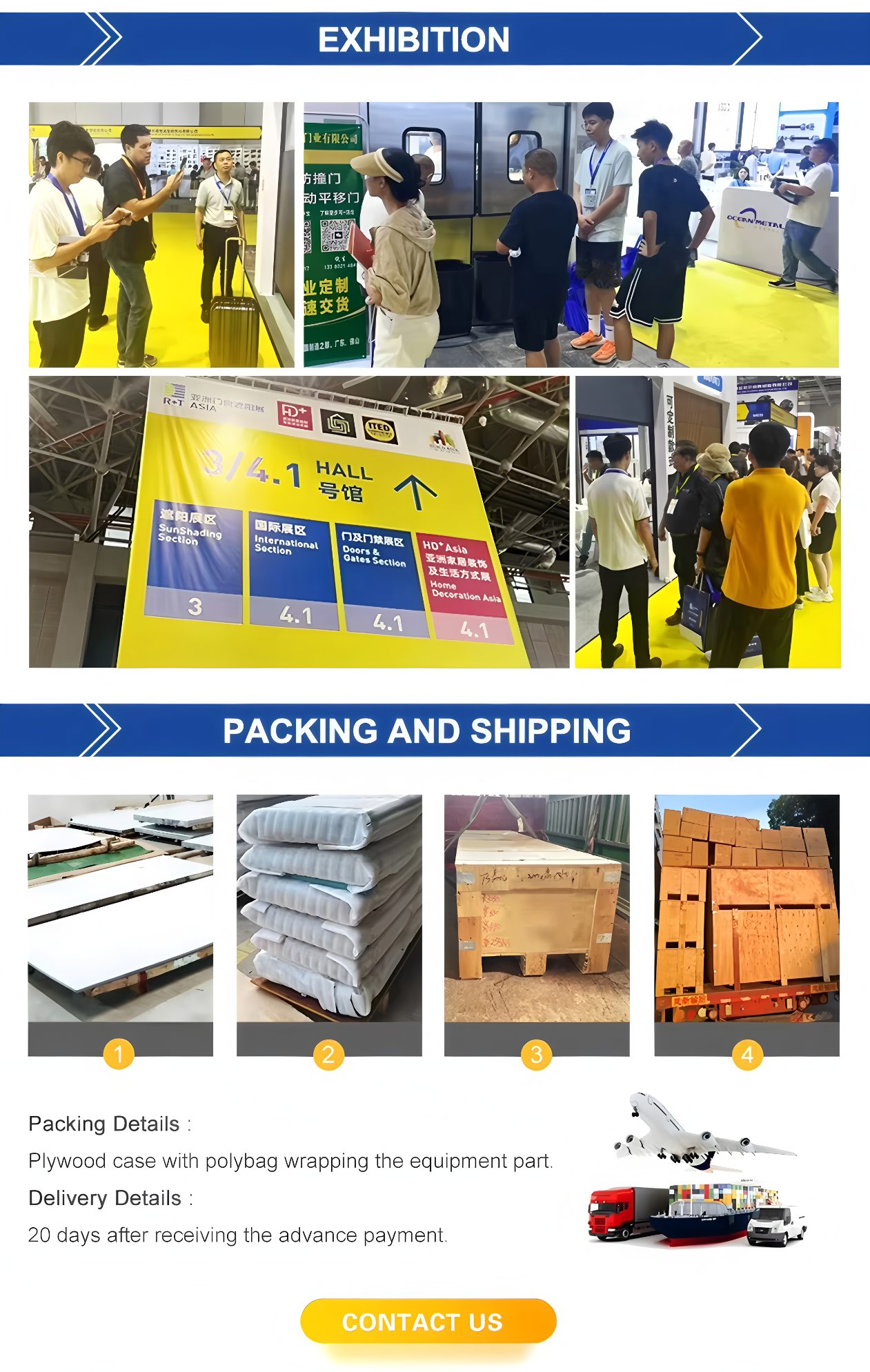

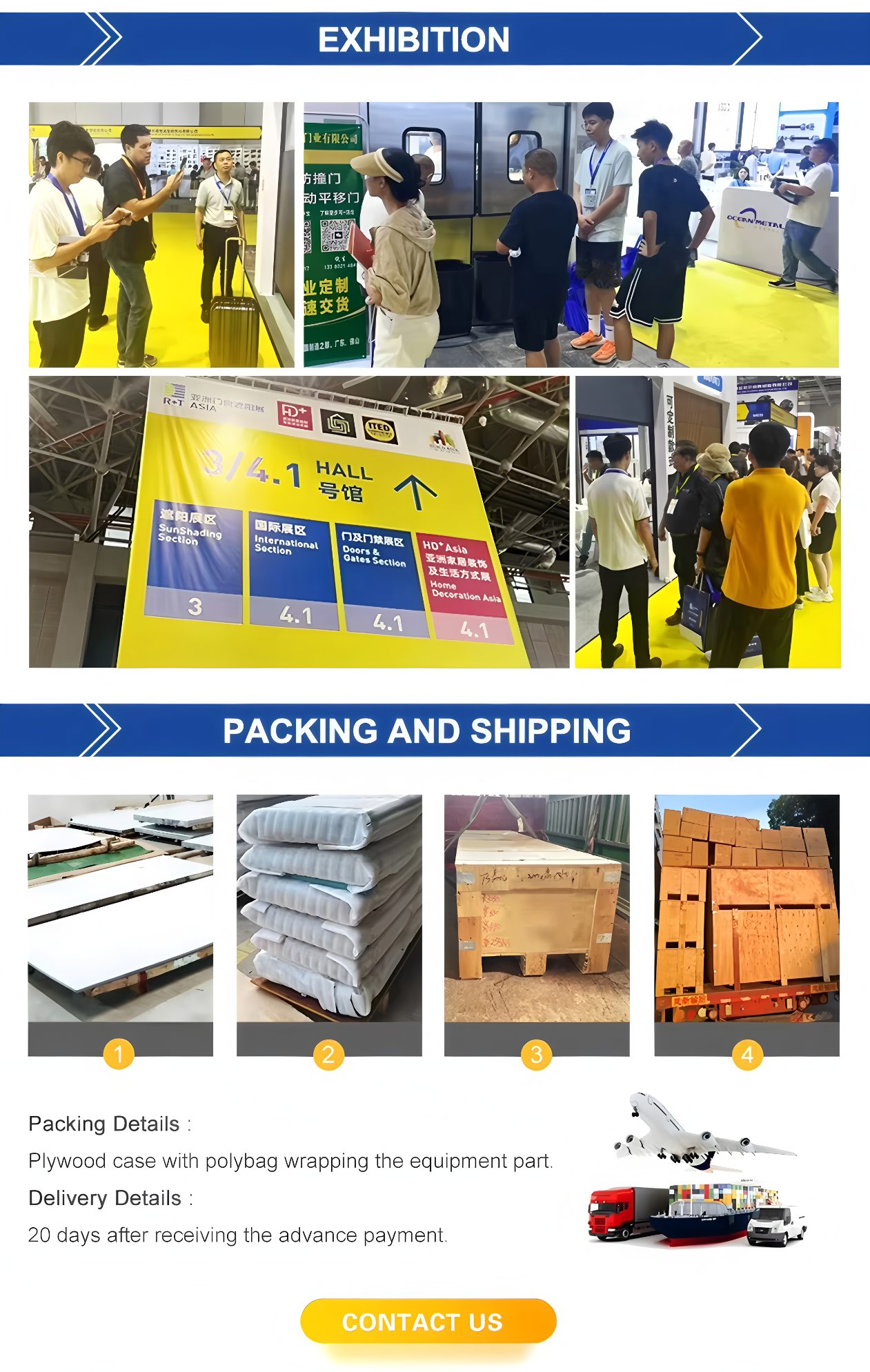

Exhibition & Package And Shipping

Product Applications

1. Hospital Clean Departments

Operating rooms, ICU wards, laboratory departments, PCR laboratories, and other areas with extremely high requirements for sterile environments, dust prevention, constant temperature, and humidity. The door effectively blocks the spread of pathogens and dust, maintaining indoor cleanliness and complying with infection control standards in medical environments.

2. Hospital Special Functional Areas

Pharmacies, vaccine storage rooms, cold-chain reagent warehouses, and other spaces requiring thermal insulation and moisture protection. The sealing structure reduces cold/hot air convection, ensuring the safe storage of medicines and reagents. For soiled passages and medical waste processing rooms, it provides sealed isolation to prevent the spread of odors and pathogens.

3. Food and Pharmaceutical Production Workshops

Food processing clean workshops, pharmaceutical GMP production workshops, health product filling lines, etc. These meet requirements for dust prevention, insect control, and cross-contamination prevention in production environments. Combined with automated integration, they adapt to the flow rhythm of unmanned production lines.

4. Precision Manufacturing and Electronics Workshops

Semiconductor production workshops, chip R&D laboratories, precision instrument assembly areas, etc. These effectively isolate dust, static electricity, and external temperature/humidity fluctuations, providing a stable environmental guarantee for high-precision production and experiments.

5. Chemical and Dust-Intensive Workshops

Chemical raw material storage rooms, powder coating production workshops, metal grinding workshops, etc. These block the leakage of corrosive gases and dust, protecting operators' health while preventing the spread of pollutants from the workshop to other areas.

After-sales Service

1. Free Installation, Commissioning, and Training

We arrange a professional technical team for on-site free installation and commissioning of the door body and control system, ensuring that operating parameters meet the usage standards of special functional areas. At the same time, we provide one-on-one operational training for the equipment management team, covering daily opening/closing, linkage settings, simple troubleshooting, and more. Operation manuals and maintenance guides will be provided.

2. Extended Warranty and Rapid Response

Core components (motor, sealing strips, sensors) come with a 2-year warranty, and the complete unit has a 1-year warranty. During the warranty period, non-human-induced damage faults are repaired or parts replaced free of charge.

3. Regular Inspections and Preventive Maintenance

During the warranty period, a technician will conduct an on-site inspection every 6 months to check door sealing performance, sensor sensitivity, motor operating status, etc. Aging wearable parts (such as brush seals) will be replaced in a timely manner to eliminate potential faults. After the warranty period, an annual maintenance agreement can be signed to enjoy discounted inspections + priority repair services, extending the door's service life.

4. Ample Spare Parts Inventory

Ensuring timely supply of replacement parts for repairs.

5. Lifetime Technical Support and Upgrade Services

We provide lifetime free technical consultation to address various issues encountered during use. For future upgrades to door linkage functions (such as integration with new access control or fire safety systems), cost-price technical upgrade services are available to adapt to hospital intelligent transformation needs.

FAQS

1. Payment Terms

Q: What are the payment terms for cooperation? Do you support installment payments or letters of credit?

A: Standard payment terms are 50% advance payment + 50% payment upon passing pre-shipment inspection. For large clients such as hospitals, installment payments can be negotiated: production starts after receipt of the advance payment, with the balance paid after on-site installation and commissioning are qualified. Overseas orders support mainstream settlement methods such as letters of credit (L/C) and telegraphic transfer (T/T), with specific terms flexibly adjusted based on the contract amount.

2. Delivery Cycle

Q: How long does it take from order placement to completion of installation? Can rush orders be prioritized?

A: The production cycle for standard-specification doors is 15-20 working days. For customized sizes or special linkage functions (e.g., integration with hospital access control systems), the cycle extends to 30-40 working days. Rush orders are supported; upon payment of a rush fee, production can be prioritized, with the fastest completion in 10 working days to meet urgent hospital procurement needs.

3. Installation and After-Sales Service

Q: Does it include on-site installation? How are subsequent faults handled?

A: The quotation includes free on-site measurement, design, installation, and commissioning services. We will arrange a professional team to visit the site, develop a customized solution based on the hospital's door opening dimensions and installation environment, ensuring the door is fully compatible with medical areas.

4. Qualifications and Certifications

Q: Does the product comply with relevant standards for medical environments? What certifications do you have?

A: This product fully complies with the Technical Code for Hospital Clean Operating Departments (GB50333), and has passed ISO9001 quality management system certification and CE certification (applicable to overseas orders). Sealing performance has been verified by third-party testing agencies, effectively blocking the spread of pathogens and dust. Relevant certification documents can be provided in electronic format for verification before contract signing.

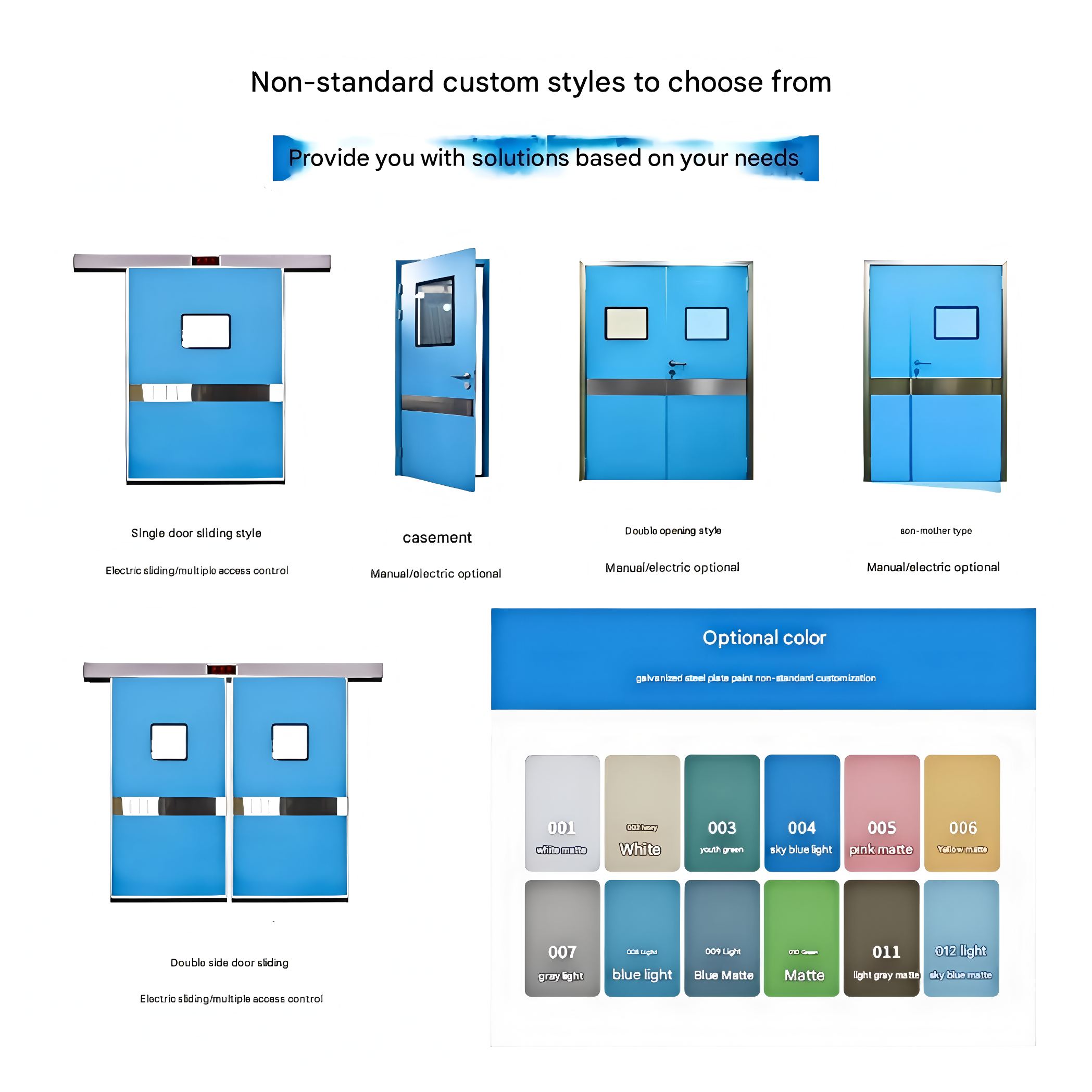

5. Customization

Q: Can it be customized according to the hospital's special door opening sizes and linkage requirements?

A: Full-size customization is supported. We can tailor the door body dimensions and installation solutions based on special door openings in areas such as hospital operating rooms or PCR laboratories. Linkage function customization is also available, such as integration with hospital access card systems, fire alarm systems, or air conditioning control systems, enabling intelligent linkage in medical workflows.

6. Product Noise Level and Hospital Suitability

Q: What is the product's noise level? Does it meet hospital quiet environment requirements?

A: The operating noise of this medical automatic sealed sliding door is **≤50 decibels**, fully complying with hospital quiet environment standards. The door features a precision silent roller track system paired with a low-noise DC reduction motor, ensuring no frictional abnormal sounds during operation. Shock-absorbing sealing strips are installed at the contact areas between the door panel and tracks, further reducing noise from mechanical vibrations. This noise level is well below the hospital ward and clinic daytime ≤55 dB and nighttime ≤45 dB environmental noise requirements, making it suitable for use in areas with extremely high quietness demands, such as operating rooms and ICUs, without disturbing medical operations or patient rest.

Procurement Advantages

1. Compliant with Medical Infection Control Standards

The multi-directional sealing structure effectively blocks the spread of pathogens, dust, and odors, meeting the environmental requirements of clean areas such as operating rooms, ICUs, and PCR laboratories. It reduces the risk of cross-infection and complies with hospital infection management regulations.

2. Intelligent Linkage Adapted to Medical Workflows

Supports multiple triggering methods, including radar sensing and access card swiping, and can integrate with hospital access control systems, air conditioning systems, and fire safety systems. In the event of a fire, it automatically opens escape passages; when medical staff or trolleys approach, it opens and closes rapidly without affecting emergency transport efficiency.

3. Safety Protection to Ensure Patient and Staff Safety

Standard-equipped with infrared safety light curtains and anti-pinch sensors, the door immediately stops or reverses upon detecting obstacles during operation, preventing collisions with medical staff, patients, or medical trolleys. In case of power outage, it can be manually pushed or pulled to meet passage needs in emergencies.

4. Energy-Saving and Cost-Reducing for Lower Operational Expenses

Excellent sealing performance minimizes cold/hot air exchange between clean areas and the outside, reducing energy consumption of air conditioning systems. The door frame and tracks are made of stainless steel or galvanized materials, offering corrosion resistance and easy cleaning, with long maintenance intervals that reduce hospital long-term maintenance costs.

5. Strong Space Adaptability and Flexible Installation

The lateral sliding opening design requires no overhead lifting space, allowing installation in areas with limited headroom above door openings, such as consultation rooms, wards, and laboratories. It does not occupy valuable indoor medical space and adapts to the complex architectural layouts of hospitals.